January 2018 Issue

January 2018

Digital EditionFeatures

Featured articles from the January 2018 issue of Modern Machine Shop

Shop Hits Home Run with Toolpath Simulation Software

Wolcott Design Services needed to improve efficiency during high-mix, low-volume runs. HMCs and Vericut tool simulation software by CGTech improved efficiency, spindle utilization and revenue.

Read More

An Automation System for a Job Shop Environment

A flexible robotic part-loading and unloading system enables a small Indiana shop to boost production without a large investment.

Read More

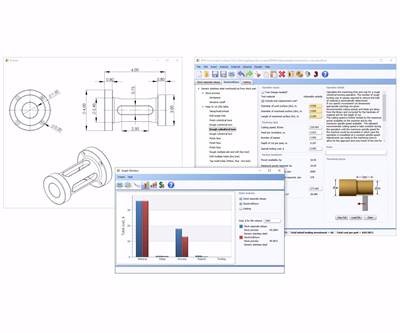

Cost Analysis Software Uses Data-Driven Model

Boothroyd Dewhurst announces the availability of DFM Concurrent Costing 3.0.

Read More

What Does It Take to Succeed at Machining Hogouts?

Beyond the machining capacity, other important factors relate to the people and the understanding of the process.

Read More

What to Know About Surface Finish Measurement

Texture is viewed differently by different manufacturing professionals, but the parameters for describing it are standard.

Read More

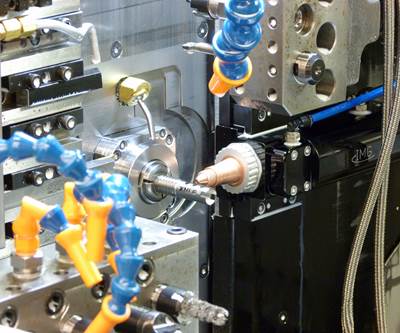

Laser Lathes Consolidate Medical Manufacturing

Laser cutting and welding capability can make Swiss-type lathes an ideal complement to equipment that hasn’t traditionally shared space with production machinery.

Read More

Adding Tilt to Trunnion-Table Turning

A modified gantry structure and other design attributes help consolidate setups even further on these five-axis machining centers. Includes video.

Read More

Machined Parts Supplier Musts and Plusses

A retired vice president of manufacturing for an oil and gas drilling equipment OEM describes the traits he looked for in potential new machining vendors as he worked to bolster the company’s supply chain.

Read MoreThe Effect of Lot Size on Productivity

The more parts to be produced, the more elaborate the manufacturing process. Here are some other important considerations that can impact productivity.

Read More

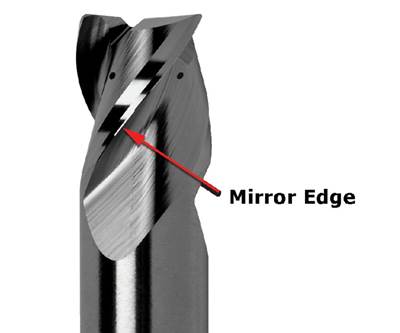

An End Mill Designed to Control Chatter

This end mill design enables it to vibrate at the same frequency as the workpiece, preventing vibration from turning into chatter.

Read More

The Link Between Gaging and Tool Cost Savings

New software delivers the next step for Renishaw’s programmable gaging system: a mechanism for changing cutting tools when they are truly at the end of their life, not after an arbitrary number of pieces have been run.

Read More

.jpg;maxWidth=300;quality=90)