February 2018 Issue

February 2018

Digital EditionFeatures

Featured articles from the February 2018 issue of Modern Machine Shop

Why Tie Payroll Hours to Machine Tool Hours?

J&R Machine uses machine-monitoring data not just to track machine uptime, but also to create a financial index that helps it shape decisions related to equipment, processes, staffing, sales and business in general.

Read More

What Is Roller Burnishing?

This process enables fast and repeatable finishing of metal surfaces to mirror-like quality, but without removing any metal.

Read More

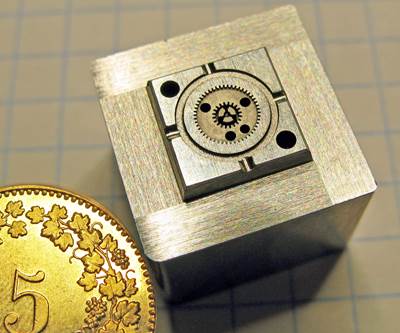

Moving Past Micro-EDM Boundaries

To push past the limits of conventional EDM equipment, this German injection molding company adopted atypical micro-EDM “milling” technology to machine small molds for tiny, critical, injection-molded parts.

Read More

CAD/CAM System Automates NC Programming

Release 5 of Tebis America’s version 4.0 CAD/CAM system is designed to help users accelerate processes without functional restrictions.

Read More

Tooling up for Deep-Hole Machining

Imparting complex geometry on the inside (and the outside) of workpieces requires the right equipment, the right cutting tools and the expertise to make the most of both.

Read More

The Value of PVD Coatings for Medical Devices

Applying a PVD coating to medical devices can offer both aesthetic and functional advantages. Here are answers to some frequently asked questions.

Read More

How to Check Roundness Between Centers

A centers-based method can be useful for checking for out-of-roundness without the need for a dedicated roundness machine.

Read More

Cybersecurity for Job Shops

Small and medium-size machining job shops can take steps to protect computerized or networked assets such as CNC machines from cyber attacks.

Read More

Face Drivers, Live Centers Now Offered

LMC Workholding now offers face drivers and live centers from Tecnologie FRB, a company which designs and manufactures products incorporating advanced technology in turning, gear cutting and grinding.

Read More

.jpg;maxWidth=300;quality=90)