Share

How do you finish the surface of a metal part to a mirror-like sheen without putting it through an abrasive process like grinding? For some applications, roller burnishing could do the trick without actually removing any metal from part.

In basic terms, burnishing is a method for polishing a surface, such as metal, through sliding contact with a harder object. The burnishing tools offered by Cogsdill Tool for machining metal use highly polished tapered steel rollers, as you can see in the photo above.

Different Approaches to Finer Roughness Values

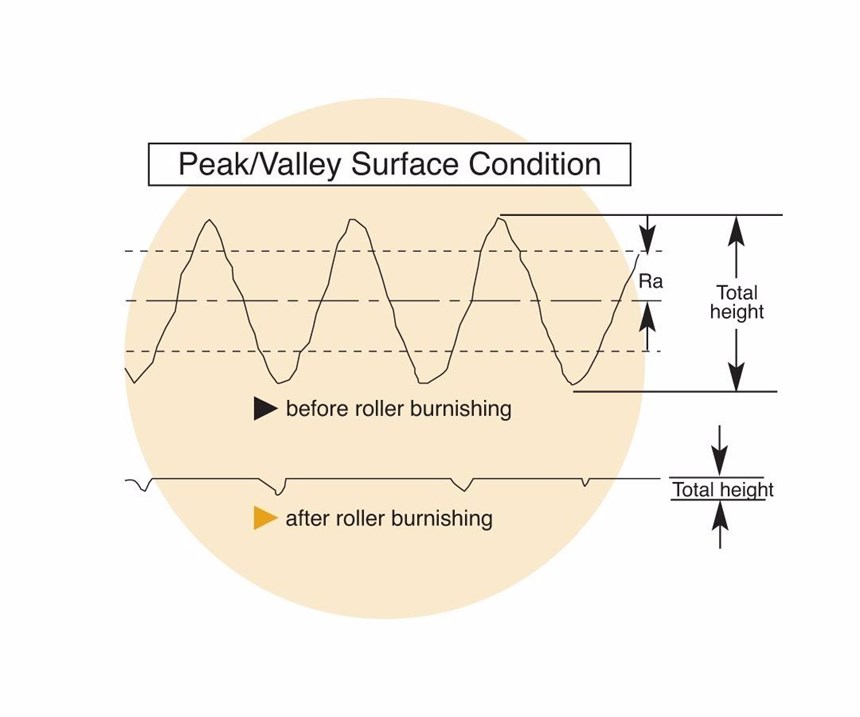

Machining a metal surface leaves microscopic peaks and valleys that are called roughness. Surface finishing, whatever the method, is about reducing the roughness average (Ra) value of the surface. Basically, the Ra value is a formula that measures the average distance between the tops and bottoms of these points relative to the mean line, which cuts through them. The finer the surface finish, the shallower the valleys and shorter the peaks.

The first noticeable difference between abrading and burnishing a surface to accomplish this peak and valley reduction is that the former removes metal from the part while the latter does not. Abrasive finishing cuts or tears away the peaks in the surface, thereby bringing the average peak and valley distances closer together. But Cogsdill says that this also leaves sharp projections in the contact plane of the machined surface. Burnishing doesn’t have this problem. At first glance, a burnished part looks as if the metal surface has been smeared smooth. But that would be incorrect. The burnishing tool’s polished and hardened rollers actually perform cold flowing of the surface and subsurface material, which results in a controlled plastic deformation of the part.

Not What It Looks Like

Material deformation comes in two varieties: elastic and plastic. Elastic deformation occurs when stress is applied at a pressure below the material’s yield point; bend a piece of plastic a little, and it bends back. Plastic deformation, on the other hand, is permanent, a result of stress at a pressure above the yield point of a given material. Crushing an aluminum can, for example, is plastic deformation.

To stick with the analogy of a soft cylinder, imagine squeezing the opposite, undimpled sides of a dimpled container to push the dimples out. That’s a bit reminiscent of what happens when roller burnishing a metal part surface.

The diagram in the slideshow above shows a profile of a hypothetical part surface before and after roller burnishing. The cold-flow effect of the rotary tool applying the rollers radially to the surface causes the peaks to flow into the valleys and the valleys to flow upward toward the peaks, creating a plateau profile whose contact plane is much less sharp than it would be after abrasion. This is important, as a common misunderstanding is that roller burnishing simply smears or pushes over the peaks to make the part smoother. Rather, cold flowing actually stimulates the material both at the peaks and a few thousandths of an inch down beneath the surface, flowing them together. Because the finish comes from subsurface effects, a burnished surface is not only smoother but also work-hardened for greater durability. Cogsdill’s Roll-a-Finish burnishing tools can be applied on a variety of ID and OD diameters, flat surfaces, tapers, contours, and fillets for final finishes down to 2 to 4 microinches Ra.

Which Parts Work for Roller Burnishing?

In the slideshow above, there is a photo of a sample part, with the unfinished surface on the left and the finished surface on the right. There are a couple things to note here. First, roller burnishing is fast and repeatable; the finish seen above was accomplished in less than 2 seconds. Cogsdill counts the fact that its tools can size, finish and work-harden parts in a single seconds-long operation as a principal benefit over grinding, honing or lapping.

Something else to note is part preparation. Not every part is suited to finishing by burnishing. Cogsdill outlines some requirements for parts that are ideal for optimum roller burnishing results:

- Material: Though almost any metal can be successfully roller burnished, ductile or malleable metals are best (for example, steel, stainless steel, steel alloy, cast iron, aluminum, copper, brass and bronze).

- Hardness: Hardness should be less than 40 HRC, ideally. (Some materials as hard as 45 HRC can be effectively burnished as well.)

- Uniformity: As evident in the sample part above, the finish depends on a uniform and tear-free surface in order for the peaks and valleys to cold flow correctly.

- Roughness: An initial 80- to 120-microinch (2- to 3-micron) surface is ideal for roller burnishing. The rougher starting finish allows for a more dramatic change in the final finish because the rollers can apply greater pressure to more of the surface.

Cogsdill’s tools are versatile and can be used on lathes, drill presses, machining centers and rotating spindles. The standard tool models are designed for right-hand rotation, with either tool or part rotating. An adjustment collar on Cogsdill’s roller burnishing tools enables the operator to set the rollers to the required diameter. The operator unlocks the collar from the interlocking bearing collar and rotates it, altering the position of the tapered mandrel relative to the tapered rolls, thereby changing the effective tool diameter. The tool can be adjusted in 0.0001-inch increments. The company’s focus lately has been on its smaller-size tools, whose compact design and rear-located adjustment mechanism enable use on multi-spindle automatic lathes and Swiss-type machines.

Related Content

How to Mitigate Chatter to Boost Machining Rates

There are usually better solutions to chatter than just reducing the feed rate. Through vibration analysis, the chatter problem can be solved, enabling much higher metal removal rates, better quality and longer tool life.

Read MoreOrthopedic Event Discusses Manufacturing Strategies

At the seminar, representatives from multiple companies discussed strategies for making orthopedic devices accurately and efficiently.

Read MoreForm Tapping Improves Tool Life, Costs

Moving from cut tapping to form tapping for a notable application cut tooling costs at Siemens Energy and increased tool life a hundredfold.

Read MoreThe Future of High Feed Milling in Modern Manufacturing

Achieve higher metal removal rates and enhanced predictability with ISCAR’s advanced high-feed milling tools — optimized for today’s competitive global market.

Read MoreRead Next

Building Out a Foundation for Student Machinists

Autodesk and Haas have teamed up to produce an introductory course for students that covers the basics of CAD, CAM and CNC while providing them with a portfolio part.

Read More5 Rules of Thumb for Buying CNC Machine Tools

Use these tips to carefully plan your machine tool purchases and to avoid regretting your decision later.

Read MoreRegistration Now Open for the Precision Machining Technology Show (PMTS) 2025

The precision machining industry’s premier event returns to Cleveland, OH, April 1-3.

Read More

.png;maxWidth=300;quality=90)