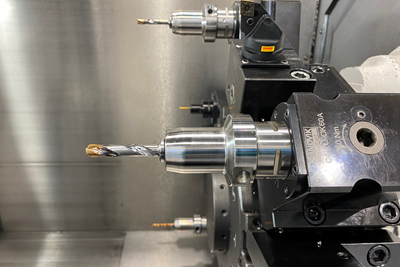

Holemaking

Whether it’s using drills to make holes, borings bars or reamers to enlarge their IDs, or taps to thread them, this is where to read up about holemaking. Holemaking is a process used to cut a hole in a part or a workpiece.

ESSENTIAL READING

VIEW ALLHow to Turn Machine Shop Downtime Into Process Expertise

To take advantage of a lull in business, JR Machine devised a week-long cutting tool event that elevated the shop’s capabilities with aerospace alloys.

Read MoreHow to Tackle Tough Angled Pocket Milling With Two Tools

Milling a deep pocket with a tight corner radius comes with unique challenges, but using both a flat bottom drill and a necked-down finishing tool can help.

Read MoreChoosing Your Carbide Grade: A Guide

Without an international standard for designating carbide grades or application ranges, users must rely on relative judgments and background knowledge for success.

Read MoreCutting Tool Technology Aids Lights-Out Machining Applications

These features can help improve cutting tool stability, standardize cutting performance and extend tool life, enabling shops to confidently run unattended shifts.

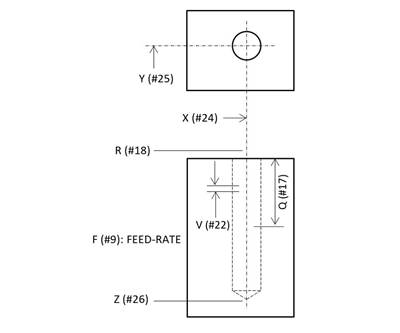

Read MoreHow to Improve Peck Drilling Canned Cycles

Most CNCs don’t have a canned cycle for machining deep holes into malleable materials. Here’s what you do.

Read MoreTips for Thread Milling Tricky Materials

Compared to tapping, thread-milling technology offers advantages for creating threads in challenging materials, such as tool steel, stainless steel and high-temperature alloys. Here are a few tips for establishing an effective thread-milling process in those materials.

Read MoreLatest Holemaking News And Updates

Scientific Cutting Tools Announces Wear-Resistant Roughing Drills

IMTS 2024: Scientific Cutting Tools introduces its line of roughing drills, specifically designed to prepare holes for SAEJ1926 and AS5202 ports, sizes -2 through -8.

Read MoreAllied Digital Readout Module Optimizes Boring Operations

IMTS 2024: Allied Machine and Engineering is exhibiting the Wolhaupter 3E tech+ digital readout module, designed to eliminate the damage of digital tooling components by cutting chips or high-pressure coolant.

Read MoreMorse Cutting Tools' High-Performance Drills Enhance Hole Quality

IMTS 2024: Morse Cutting Tools reintroduces its Shear Drill line, featuring advanced cutting geometry and various sizes for versatility.

Read MoreETP Transmission Toolholders Feature Hydraulic Clamping

IMTS 2024: ETP Transmission showcases its Hydro-Fix Swiss hydraulic clamping toolholders, designed to handle 26 different shank sizes, accelerating cutting tool changes.

Read MoreEngis Boring Tool Provides Burr-Free Finishes

IMTS 2024: Engis Corp. presents its Engis Hybrid solution for boring finishing processes, designed to produce sharper, burr-free finishes on cross holes and meter edges within the part.

Read MoreWalter Boring Bars Provide Fast, Precise Tool Changes

The Walter QuadFit cylindrical modular interface enables quick and easy replacement of exchangeable heads.

Read MoreFeatured Posts

Custom PCD Tools Extend Shop’s Tool Life Upward of Ten Times

Adopting PCD tooling has extended FT Precision’s tool life from days to months — and the test drill is still going strong.

Read MoreForm Tapping Improves Tool Life, Costs

Moving from cut tapping to form tapping for a notable application cut tooling costs at Siemens Energy and increased tool life a hundredfold.

Read More10 Ways Additive Manufacturing and Machining Go Together and Affect One Another

Forget “additive versus subtractive.” Machining and metal additive manufacturing are interconnected, and enhance the possibilities for one another. Here is a look at just some of the ways additive and machining interrelate right now.

Read MoreNew Machining Technology Works With Old to Restore WWII Submarine

A set of donated boring bars that can be used in a 1954 boring head will enable volunteer machinists to recreate a pair of binoculars for the USS Pampanito.

Read MoreHow to Turn Machine Shop Downtime Into Process Expertise

To take advantage of a lull in business, JR Machine devised a week-long cutting tool event that elevated the shop’s capabilities with aerospace alloys.

Read MoreHow Lowering Torque Improves Tapping Tool Life

Escaping the tap breakage trap requires a long look at torque and the many factors that influence it.

Read MoreFAQ: Holemaking

What Are Carbide Coatings?

Most modern carbide inserts and solid carbide tools are coated with a thin film (between 3 and 20 microns, or 0.0001 to 0.0007 inch). The coating is typically composed of titanium nitride, aluminum oxide and titanium carbon nitride layers. This coating increases the hardness and creates a heat barrier between the cut and the substrate.

What is a counterbore?

Counterboring is a machining operation that will enlarge an existing hole’s diameter to a specified depth. Traditionally, counterboring is done with either a special counterboring tool that has a pilot, or it is done with an end mill. In either case, the diameter of the tool (end mill or counterbore) must match the diameter that is counterbored.

Traditional counterboring is great for smaller holes, but as holes get larger, the cutting tools get more expensive.

What is countersinking?

A countersink is a functional surface upon which a fastener head bears. Because fastener performance is so important, countersink tolerances are critical.

What is a chamfer?

Hole chamfers are usually specified simply to make it easier to insert a screw, pin, bushing, or other assembly component. The component doesn't bear on the chamfer, so diameter and angle tolerances are usually not critical to the part's performance.

Holemaking Supplier Categories

- Deep Hole Drilling Machines (Gun Drilling)

- Boring Tools & Heads for Machining Centers

- Drills

- Drill Bushings

- Fixtured Drilling & Tapping Units

- Boring Tools

- Multi-Spindle Drilling Machines

- CNC Drilling & Tapping

- Radial Arm Drilling Machines

- Drilling Heads/Attachments

- Bench & Column Drilling Machines

- Gundrills

- Boring Tools for Turning Machines

- Reamers

- Drill Chucks

.png;maxWidth=300;quality=90)

.jpg;maxWidth=300;quality=90)