Turn/Mill

The Knowledge System

This company sees knowledge to be a vital production resource. Capturing and sharing information are now routine functions on the shop floor. Here are lessons the company learned.

Read MoreB-Axis Turn/Mills Have Their Place

The additional rotary milling axis on these machines allows them to complete many types of complex parts in a single setup, but these machines have gained a reputation for being difficult to program. Today’s CAM software, however, eases the programming challenge significantly.

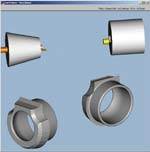

Read MorePrototyping Productivity

A manufacturer of hermetic compressors proves out a new strategy based on multi-process machining.

Read MoreServing The Human Machine

A New Hampshire manufacturer spurs growth by expanding the medical segment of its business.

Read MoreNew Borders For Swiss-Type Turning

The traditional niche may be too narrow. This shop uses sliding-headstock lathes for jobs that wouldn't normally be run on this type of machine.

Read MoreOrthodontist Turns To CNC Swiss To Manufacture His Device

This orthodontist decided to take the plunge into CNC Swiss after having difficulty finding job shops with the machining time to make his parts, tiny components that go into an orthodontic appliance.

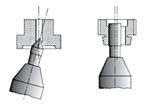

Read MoreWhen Does Hard Turn/Grind Make Sense?

Combining different operations on a single machine tool platform is an attractive and increasingly popular idea. It is in practice, however, not always a plug and play substitution. Optimizing distinct metalcutting operations into a single cycle takes planning and a good understanding of the pluses and minuses of each.

Read MoreTurning Centers Yield Solutions With Support

When this process engineer went searching for new turning centers for the Black&Decker plant in Fayetteville, North Carolina, he knew that he needed reliable machines, but he did not have a specific vendor in mind.

Read More

.jpg;maxWidth=300;quality=90)