Orthodontist Turns To CNC Swiss To Manufacture His Device

This orthodontist decided to take the plunge into CNC Swiss after having difficulty finding job shops with the machining time to make his parts, tiny components that go into an orthodontic appliance.

Share

Dr. Stephen Hanks (Las Vegas, Nevada), an orthodontist who is also an adjunct professor at the UCLA School of Dentistry and an ordained Mormon minister, has added a few more titles to his résumé: manufacturing engineer, CNC Swiss programmer and setup person. These have been added in rapid succession since July of 2001, when Dr. Hanks decided to get into the Swiss machining business and culminated in January 2002 with his acquisition of a six-axis CNC Swiss-type lathe.

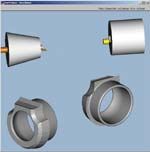

Dr. Hanks decided to take the plunge into CNC Swiss after having difficulty finding job shops with the machining time to make his parts, tiny components that go into an orthodontic device called a Herbst appliance. But before he made the investment, he wanted to be sure he could handle the complex CNC programming such a venture would entail. So he purchased PartMaker SwissCAM from IMCS Inc. (Fort Washington, Pennsylvania).

"I bought PartMaker SwissCAM to help me understand the concept of Swiss-turning," says Dr. Hanks. "That helped prepare for buying a machine."

Herbst appliances are designed to correct an overbite caused when the lower jaw is set too far back in the mouth. Often this condition is misdiagnosed as a regular overbite (where the upper jaw protrudes too far over the lower jaw).

Dr. Hanks himself suffered from this condition but refused to undergo the painful surgery necessary to correct it. Introduced to the concept of Herbst at an orthodontic conference in 1978, Dr. Hanks applied what he learned to cure his condition. He designed and built his own Herbst device, which he began using in 1992. He wore the appliance for 15 months and then began modifying and advancing the traditional Herbst design.

Dr. Hanks sought to produce and sell his device to other orthodontists. His goal was to exhibit at the American Association of Orthodontists Convention in May 2002. In the fall of 2000, he sent his designs to more than 30 CNC Swiss job shops. He was disappointed when only one company responded. Dr. Hanks concluded that he would be better off buying a CNC Swiss and machining his parts on his own if he wanted to complete them in time for the show.

"I figured it would cost a minimum of $50,000 to have my parts made, because I would have to commit to a certain level of product with no guarantee of selling any of it," Dr. Hanks says. "If I bought the machine and made the parts myself, I would not have to eat the inventory and would at least have the machine to resell if the venture did not work out."

Dr. Hanks settled on a Hanwha SL20HP Swiss-type lathe after feeling comfortable that he could use PartMaker SwissCAM to program it.

"Not having a CNC background and not being able to write G & M codes, PartMaker was the bridge from my part design to creating a part on the machine," says Dr. Hanks.

PartMaker is an off-line CAM programming software for multi-axis lathes with live tooling and CNC Swiss-type lathes. The software relies on a visual programming approach that operates from graphical representations of the various faces of the part. The software divides the part into planar or rotational faces that are graphically represented on the screen. The appropriate machining operations are then assigned to each face. The complete program becomes the sum of all of the machining operations on all of the faces.

PartMaker is a knowledge-based machining system. It includes an integrated tool database with data for the tools used on the machine tool being programmed. For repetitive operations such as center drilling, drilling, tapping, boring, chamfering and so on, the programmer needs only to create the cycle one time. The cycle can be stored in a cycles database, which is linked to the tools database. The software comes with a materials database with recommendations for average cutting parameters. Feed rate and spindle speed are computed based on tool geometry and machineability data.

When the programmer is satisfied with the views of the part and its job plan, he or she can proceed to post processing to automatically generate an NC program for a particular multi-axis lathe. Multiple programs with synchronization points are generated for Swiss-type lathes that require a separate program for each set of programmable axes. The software eliminates the need to manually edit the generated NC program.

PartMaker performs a full 3D simulation of the Swiss machining process on screen so the programmer can see any errors before machining the part. This allows the user to see part transfer and simultaneous operations being carried out on the main and sub spindles at the PC. Once the simulation is completed, the user can analyze a solid model of the machined part.

For Dr. Hanks, PartMaker allows him express his concepts in a method his CNC Swiss can understand.

"PartMaker writes the whole program," says Dr. Hanks. "This means I can conceptualize a part on Tuesday, program and set it up on Wednesday, machine it Thursday and have it by Friday to put into a patient's mouth for testing. That is unheard of in the industry."

Related Content

German Project Yields Three New Medical Machining Processes

Trends to Watch at IMTS: Recent research has resulted in a new mix of high-speed turn whirl milling, polygon turning and rotational turning for manufacturing medical bone screws and out-of-round nails.

Read MoreAmetek EMC Laser Cutting System Offers Through-Part Cooling

The new laser cutting system offers comprehensive Swiss machining capabilities, as well as through-part cooling and automatic part-handling options.

Read MoreSupercritical Success for Medical Machining

High-pressure carbon dioxide coolant can dramatically improve the production rate of titanium parts while leaving no residue — an excellent fit for medical machining.

Read MoreOrthopedic Event Discusses Manufacturing Strategies

At the seminar, representatives from multiple companies discussed strategies for making orthopedic devices accurately and efficiently.

Read MoreRead Next

5 Rules of Thumb for Buying CNC Machine Tools

Use these tips to carefully plan your machine tool purchases and to avoid regretting your decision later.

Read MoreSetting Up the Building Blocks for a Digital Factory

Woodward Inc. spent over a year developing an API to connect machines to its digital factory. Caron Engineering’s MiConnect has cut most of this process while also granting the shop greater access to machine information.

Read MoreRegistration Now Open for the Precision Machining Technology Show (PMTS) 2025

The precision machining industry’s premier event returns to Cleveland, OH, April 1-3.

Read More

.jpg;maxWidth=300;quality=90)