Turn/Mill

From Out Of The Lab

Disruptive technology's purpose is to disrupt the way machining is done. This article includes some of the developments to come out of the Machining Technology Laboratory (MTL), an R&D initiative dedicated to finding innovations in metalworking processes.

Read MoreA Fresh Face In Machining

It's late Friday night. While other 19-year-olds may be enjoying a movie or perhaps just hanging out with friends, Michael Goetz is programming a job on a mill-turn. The owner of Lombard, Illinois-based Goetz Industries is no stranger to hard work. In fact, in addition to completing coursework, he worked at least 50 hours per week while enrolled in high school.

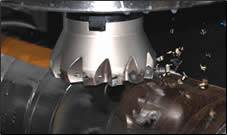

Read MoreRealizing Large-Scale Savings On Large-Scale Parts

Converting big square bars to largely round tie bars used to require 24 hours per piece at Oak Products. The Sturgis, Michigan, company can now complete the same job in 8 hours. How did the company slash its machining times and realize substantial cost savings? Oak attributes the turnaround to process re-engineering involving aggressive mill-turning and tooling geared to stand up to the challenge.

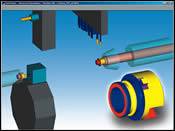

Read MoreCAM Software As A Creativity Tool

This job shop relies on its CNC programming software to unlock the productivity of its multi-axis, multi-tasking machine tools and CNC Swiss-type machines.

Read MoreSucceeding Beyond A Specialty

This shop watched its chosen niche become less profitable. Its response was a dramatic investment in new equipment, along with an information-related change that has made all of the shop’s equipment more cost-effective.

Read MoreTurning Without Rotating The Part

For large or unbalanced parts, this machining center can perform turning or boring operations using its programmable U axis.

Read MoreThe Multi-Process Machine Mindset

Installing a machine tool that combines milling, turning, boring and other processes changed this job shop’s outlook.

Read More

.jpg;maxWidth=300;quality=90)