Tooling

Milling Tools For Dental Applications

The company’s line of milling tools features cutting geometries and coatings engineered specifically for dental applications.

Read MoreThread Milling Cutters

Acme and stub Acme thread milling cutters are available in thread sizes ranging from 1/4"-16 to 1" - 5.

Read MoreCutting Tools, Fluids For Aerospace Machining

Cyclo Cut cutting tools include indexable milling tools, rotary cutting tools and toolholders for roughing, semi-finishing and finishing operations.

Read MoreAutomated Drill Sharpening

The XT-3000 sharpener now features a completely automated drill-sharpening function to enable faster and more consistent sharpening.

Read MorePrecision Boring Systems

The CBER precision modular boring system converts ER collet holders into precision boring systems.

Read MoreSynchronous Tapping Holder And More

The company says its synchronous tapping holder, the Mega Synchro, compensates for synchronization error during rigid tapping by reducing the thrust load to both the tap and workpiece.

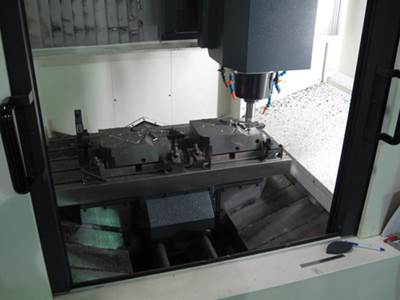

Read MoreWhen to Mill Keeps Changing

Technology improvements steadily expand the range of tool and die parts that justify high speed machining.

Read MoreVideo: Setting Boring Bar Offset On A Swiss-Type

This video clip from a MasterTask Training instructional course describes how to set the X-axis geometry offset for a boring bar on a Tsugami Swiss-type lathe.

WatchDrill Combines Modular, Solid Carbide Characteristics

Widia’s Victory Top Drill M1 modular drill, part of the company’s Victory platform of advanced milling, turning and hole making tools, is said to combine the economic benefits of modular drilling systems with the machining performance and hole quality of solid carbide tools.Available over a standard diameter range of 0.3150" to 0.8264" (8 to 20.99 mm) and at length-to-diameter ratios of 3×D and 5×D, drill bodies are available in either flanged-shank (metric) or round-shank (inch) configurations.

Read MoreHydraulic Expansion Toolholders

The vibration-damping capabilities of Schunk’s high-precision Tendo-E hydraulic expansion toolholder are said to increase tool life, improve surface quality and minimize stress on the spindle. The toolholder can be changed without additional peripheral equipment and features an axial length-setting screw for quick tool-presetting.

Read More

.jpg;maxWidth=300;quality=90)