Tooling

Composites Machining for the F-35

Lockheed Martin’s precision machining of composite skin sections for the F-35 provides part of the reason why this plane saves money for U.S. taxpayers. That machining makes the plane compelling in ways that have led other countries to take up some of the cost. Here is a look at a high-value, highly engineered machining process for the Joint Strike Fighter aircraft.

Read MoreFind Your Speed Outside of Machining

This short-lead-time mold shop achieves its most significant time savings by looking outside the machining cycle. However, one of those elements outside the cycle—palletized setup—ultimately led to cycle time savings via five-axis machining.

Read MoreWhat Don’t you Like About that Canned Cycle?

Almost all CNC users take advantage of control-based canned cycles. Even CAM systems commonly output G-code programs that contain canned cycle commands. This includes hole machining canned cycles, such as drilling, tapping, boring and more, and whatever milling cycles the machine may have. For turning centers, it includes roughing and finishing multiple repetitive cycles.

Read MoreBenchmark Your Machining Knowledge

Ryan Pohl, president of Expert Technical Training, says his company gives a 20-question, multiple-choice test to shops to evaluate their need for his firm’s “Advanced CNC Milling and Drilling” course. The questions cover important points—though not necessarily basic points—related to tools, toolholders, machine design and cutting parameters. Here is a link to the questions.

Read MoreJust don’t Call it Vibration

The device for rapid peck cycles holds the drill like a toolholder.

Read MoreAdvanced CNC Milling and Drilling Quiz

A provider of machine shop training offers these questions for benchmarking metalworking knowledge.

Read MoreInsert Coating Makes the Grade in Progress Initiative

Exchanging turning inserts for Seco’s Duratomic-coated grade TP2500 helped this manufacturer reduce per-part and perishable tooling costs by 20 and 70 percent, respectively.

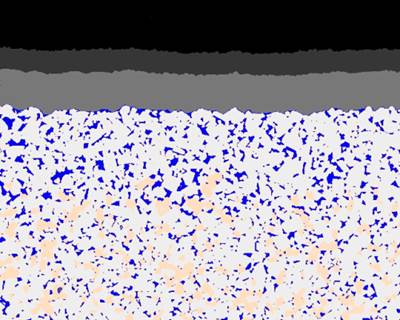

Read MoreAtomic-Level Coating Manipulation Adds Durability

Seco's Duratomic-grade inserts are said to run faster and longer than competitive models. Key to their performance is a unique texture achieved by manipulating the coating at the atomic level.

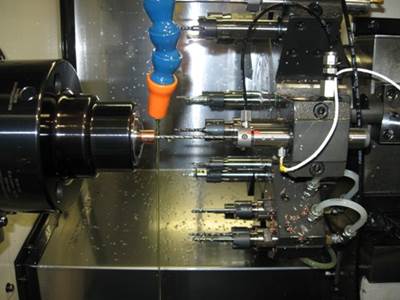

Read MoreDrilling with Modulation Delivers Pecks for Free

A system for center drilling on Swiss-types and other small lathes oscillates the drill up to 1,000 times per second. Cycle time, part quality and predictability all improve.

WatchVideo: Modulation Assisted Machining

This footage shows the effect of a techology that speeds and simplifies center drilling by oscillating the drill through many pecks per second.

Watch

.jpg;maxWidth=300;quality=90)