Insert Coating Makes the Grade in Progress Initiative

Exchanging turning inserts for Seco’s Duratomic-coated grade TP2500 helped this manufacturer reduce per-part and perishable tooling costs by 20 and 70 percent, respectively.

Share

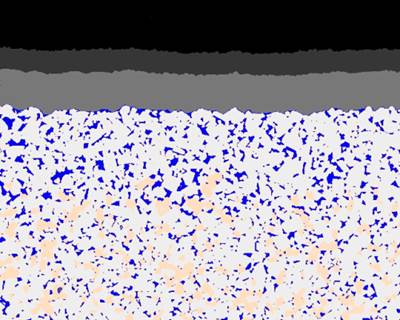

Although advancements in cutting tool technology typically have been incremental, one cutting tool manufacturer says its custom methodology for developing coatings represents a bigger change than the typical new grade or geometry. While toughness and wear resistance are usually considered diametrically opposed, the Duratomic coating process developed by Seco Tools (Troy, Michigan) is said to improve both properties simultaneously. The result? Inserts with both improved cutting capability and prolonged tool life, the company says.

This claim is born out by the experience of Tivoly, a close partner of Seco. This Derby Line, Vermont-based shop recently acquired the capability to cut more aggressively, reduce cycle times, and reduce per-part and tooling costs by 20 and 70 percent, respectively—all without any major changes to its manufacturing processes. Rather, the lion’s share of the credit for these productivity gains went to the first Seco insert grade to incorporate a Duratomic-developed coating. "Without Duratomic, improved cost through cycle time reduction would not have been possible unless we made a big investment in capital equipment and totally revamped our processes," says Scott Gowdy, Tivoly plant manager.

Few companies can trace their heritage as far back as Tivoly, which got its start manufacturing a cutter designed to restore worn wagon axles in 1880. The company evolved into part of the Union Butterfield Corporation until it was sold to French-owned Tivoly Inc. in 1989. Today, its product range includes hand taps, production taps, performance taps, application taps, carbide taps, specials, reamers and drills, many of which are private-labeled for other cutting tool manufacturers. The company says one key to its corporate longevity is a focus on progress that incorporates a commitment to continous improvement and a recognition that change is necessary and inevitable.

Another key to success, however, is a focus on partnerships with both customers and suppliers—suppliers like Seco, which provides more than 50 percent of the company’s cutting tool needs. In 2006, as part of its commitment to progress, Tivoly began a formal process-improvement/cost-reduction initiative in collaboration with Seco technical specialist Joe Mecus and Seco distributor Matt Murray of Blanchard Industrial Supplies. The two visited Tivoly weekly and spearheaded monthly meetings between the two companies to assess machining operations and decide where productivity gains or cost savings could be achieved most easily.

At the time, Seco had just announced its first Duratomic-developed coating for grade TP2500. "Matt offered us free samples and explained to us how the Duratomic process actually alters the aluminum oxide coating at an atomic level, changing the grain direction to make it more wear resistant," says Roger Stoddard, Tivoly’s design/applications engineer. (For more information about the Duratomic process, link to the article "Atomic-Level Coating Manipulation Adds Durability" under "editor's picks" at the top right of the page).

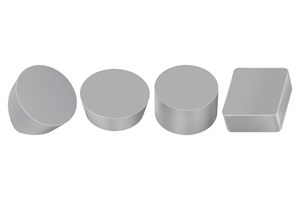

Designed for general steel turning applications, TP2500’s functionally graded substrate structure is said to increase edge toughness without sacrificing strength for the bulk of the material. The first test at Tivoly involved turning an 0.05-inch standard tap blank in M1 tool steel. For this application, the company had run indexable inserts on a Citizen L25 Swiss screw machine at 600 sfm, a feed rate of 0.005 ipm and a cutting depth of 0.06 inch to achieve 150 parts per cutting edge. Applying the Duratomic-coated TP2500 grade with an MF5 chipbreaker geometry improved the process to 1,500 parts per cutting edge—without changing any of the original cutting parameters.

The three-prong, crown-shaped MF5 chipbreaker design includes chip deflectors and cooling ditches. According to Seco, these features are beneficial at low depths of cut (between 0.02 and 0.1 inch), while the chipbreaker’s open geometry reduces cutting forces. The manufacturer adds that when used in combination with grade TP2500, tool life often improves by a factor of 10.

Encouraged by the successful application of the grade in the tap blank operation, the team then targeted an M11 tool steel application running on a Mazak SQT200MS CNC lathe. Machining speed was 300 sfm with an 0.003-ipm feed rate and a 0.05-inch cutting depth. Applying the TP2500 grade, again with the MF5 chipbreaker geometry, increased productivity from 40 to 200 parts per edge. "Few initial process changes were required on any of these operations, and depending on the application we realized tool life improvements ranging from 300 to 1,000 percent," Mr. Stoddard notes.

However, improvements stemming from the use of the new grade didn’t end there. Mr. Mecus offered suggestions on standardizing Tivoly’s carbide tools in order to reduce the large number of different inserts it kept in inventory. As a result, annual consumption of turning inserts decreased from 751,200 to 1,252. This reduced spending on perishable tooling by approximately 70 percent.

That said, perishable tooling represented only a small piece of the production cost pie. The company realized greater benefits through cycle time reductions. Although initial tests used the same feeds, speeds and cutting depths as previous tools, the company soon found that the Duratomic-coated TP2500 grade enabled it to overcome previous limitations on these parameters in some applications. Cutting more aggressively—often to the point of maxing out the capability of a given machine—reduced cycle time on roughing operations by 50 to 80 percent, approaching speeds ranging to 1,500 sfm in tool steel operations that previously ran within the 500 to 700 sfm range.

The new inserts’ predictable performance and suitability for a variety of materials contributed to additional cost savings. That’s because the company no longer had to devote significant engineering and programming resources to change cutting parameters for thousands of different parts in small lot quantities. Combined with the cycle time reductions, this reduced per-part costs by 20 percent.

Related Content

Shoulder Milling Cuts Racing Part's Cycle Time By Over 50%

Pairing a shoulder mill with a five-axis machine has cut costs and cycle times for one of TTI Machine’s parts, enabling it to support a niche racing community.

Read MoreBig Daishowa Chuck Eliminates Chatter in Milling Operations

The Mega 12DS chuck is designed for trochoidal milling with anti-vibration end mills.

Read MoreWalter Ceramic Inserts Enable Efficient Turning, Milling

Suitable turning and milling applications of the WIS30 ceramic grade include roughing, semi-finishing and finishing, as well as interrupted cuts.

Read MoreThe Impact of Cutting Teeth Spacing on Machining Stability

Many cutter designs are available, and variable teeth spacing (or variable pitch) cutters can be used to influence milling stability. Let’s discuss why teeth spacing affects stability.

Read MoreRead Next

Atomic-Level Coating Manipulation Adds Durability

Seco's Duratomic-grade inserts are said to run faster and longer than competitive models. Key to their performance is a unique texture achieved by manipulating the coating at the atomic level.

Read MoreRegistration Now Open for the Precision Machining Technology Show (PMTS) 2025

The precision machining industry’s premier event returns to Cleveland, OH, April 1-3.

Read MoreBuilding Out a Foundation for Student Machinists

Autodesk and Haas have teamed up to produce an introductory course for students that covers the basics of CAD, CAM and CNC while providing them with a portfolio part.

Read More

.png;maxWidth=300;quality=90)