Find Your Speed Outside of Machining

This short-lead-time mold shop achieves its most significant time savings by looking outside the machining cycle. However, one of those elements outside the cycle—palletized setup—ultimately led to cycle time savings via five-axis machining.

Share

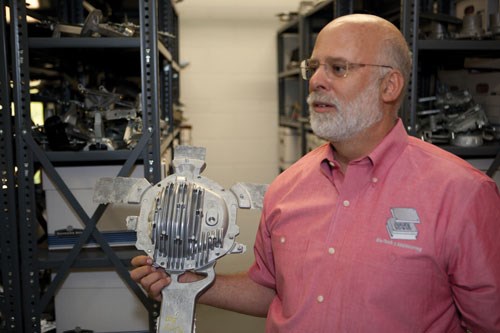

At Die-Tech and Engineering (DTE), a mold shop in Wyoming, Michigan, die-cast dies and injection molds are milled through five-axis machining.

Not 3+2 machining. That is, not merely by pivoting the tool or workpiece angle outside the cut. Rather, DTE uses two five-axis Mikron machining centers with linear-motor rotary axes to machine all manner of die and mold components via fast milling cuts that flow from one compound angle to the next.

“I don’t see why any mold shop wouldn’t want to use full five-axis machining,” says DTE president William Berry.

Yet five-axis machining waited for its moment in this shop. Despite how uncommon it is for a mold shop to use continuous five-axis milling so pervasively, DTE has no interest in being a novel or leading-edge user of technology. In fact, some widely established technologies have only recently come into use in this shop—a CMM, for example. The shop’s philosophy, in Mr. Berry’s words, is “appropriate use of technology.” That is, new methods and techniques are incorporated only when they can assist the shop in drastically reducing the lead times it quotes to customers.

In one memorable case, an “emergency” die illustrated how far the focus on lead time has taken this shop. The tool for an automotive die-cast part (see photo on previous page) had to be delivered in just over 3 weeks because of a late and significant design change. The customer expected each bidding supplier to add a premium for the tight delivery of the new tool. But DTE insisted on charging its standard price. Doing so was easy and appropriate, not only because the shop already had work from this customer that it could delay to make room, but also because delivering the die within about 3 weeks fit squarely within the standard lead time that the shop would otherwise quote for such a job.

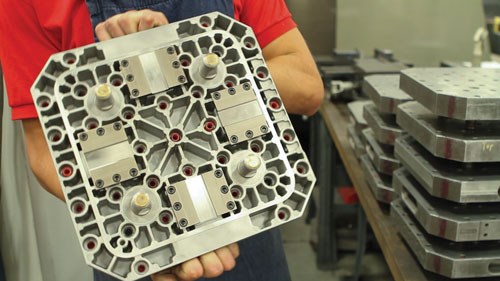

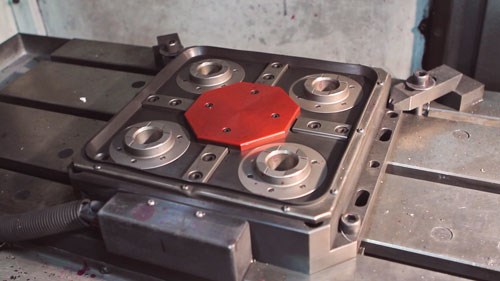

How the shop achieves this rapid turnaround on complex die and mold work is worth studying. The enabling technology is not five-axis machining. In fact, five-axis milling is the only distinctive element of the shop’s process that actually focuses on faster metal removal. A better candidate for the technology most important to this shop’s tight delivery times would be palletization—something that saves setup time rather than machining cycle time. Using the Erowa palletization system, DTE runs jobs on engineered pallets that lock precisely into mating receivers at the machines. Palletization came first at this shop, and it was the key to using five-axis machining effectively.

But as significant as any enabling technology might be, the shop’s enabling mindsets might be just as important. These, too, have their impact outside the cycle. One of these mindsets has been mentioned—appropriate use of technology. The other is simultaneous engineering (more on this below). In either case, this mold shop’s approach to speed does not focus excessively on high speed machining or any other means of getting the metal out faster. There is actually very little lead time gain to be found there, Mr. Berry says. Instead, most of the best opportunities for lead time savings relate to all of the less-well-defined work that a mold shop has to do before the majority of the machining can begin.

Simultaneous Engineering

A job doesn’t linger at any point within DTE, not even in the office—not even on an engineer’s desk. That is, no job delays long enough to become an involved undertaking for any single engineer.

To make certain of this, the shop makes a distinction between “project engineering” and “manufacturing engineering”—two disciplines required for any job. Keeping the disciplines separate streamlines the work, Mr. Berry says.

The project engineer focuses on the big picture. This engineer sees the job as primitive elements, defining the composition of the mold or die to just the level of detail necessary to win the customer’s approval, order steel and begin the most basic machining work. Then, the manufacturing engineer creates 3D tool paths. Every job passes through both engineers—and metal removal has already begun before either is done.

In fact, every job passes through two very capable engineers. DTE’s project engineers have masters-level educations. Manufacturing engineers have all stuck with the company through a demonstrated ability to produce efficient programs at a rapid pace. Coordinating with them are shopfloor personnel who are similarly distinctive. A die maker at DTE is not just the machining craftsman that the word usually implies. Rather, the skilled personnel on DTE’s shop floor are also valued for their ability to visually verify that a machining process programmed quickly is performing as it should. They are also valued for time management, as there is no scheduling software here. Shop floor lead personnel take responsibility for the challenge of organizing and prioritizing the complex work as it moves rapidly through the machining area.

Lock-In Loading

The Erowa palletization system ensures that setups in this fast process are quick and reliable—whether at DTE’s machining centers or EDM machines. The beauty of the system is that it allows any job to be run on a series of machines as easily as it could be run on just one machine, without increasing setup time or the likelihood of error. Pallets are released from one machine and reliably locked into another with little delay. Realizing this advantage has changed the pace and thinking of the shop.

DTE was one of the first users of this system in North America. The shop even realizes this precision location on parts that are too large for the pallet, using magnetic workholding to support parts that hang past a pallet’s edge.

Mr. Berry says shops often waste money on high speed machines. The potential productivity of a high speed machine is lost if the spindle has to wait while an operator meticulously sets up the job.

Something similar is true of extremely precise machines. Shops don’t appreciate how easily their own setup errors overwhelm any precision improvement that might be built into a higher-end machine tool.

Palletization overcomes these areas of waste. By bypassing the traditional setup process for a die/mold part, the system lets the machine tool deliver much more of its potential precision and productivity. Implementing palletization was the most significant step the shop has ever taken, Mr. Berry says. The use of the system accelerated the shop’s heartbeat, radically redefining how much machining work the shop can be expected to carry out over the course of a typical day.

Contour Cutting

Embracing fast setups ultimately laid the foundation for the step that most affected the machining time itself: five-axis machining. Milling in five axes increases machining speed two ways: by letting the shop use shorter and more rigid tools to reach recessed features, and by letting the shop take wide cuts with flat-bottom tools in place of ballnose cutters. The machines from Mikron (now AgieCharmilles) use linear motors on the rotary axes to achieve smooth, coordinated motion during the precise sweeps with flat-bottom tools.

Palletization was pivotal for the use of five-axis machining largely because the machines are just too valuable to sit idle. They are too valuable even to do roughing if there is finishing work to be done. In short, the machines have to be used productively—and with the Erowa system, they can keep making chips for as long as there is work. No machining time is lost while setups are performed. In fact, the machines can keep on making only valuable chips, because low-value roughing can be done on a three-axis machine before the work is clamped quickly onto a five-axis machine for finishing. In this way, DTE realizes the full value of fast machining capability. And it does this within a process that has already been engineered for speed outside of the machine tool as well.

Related Content

Inside the Premium Machine Shop Making Fasteners

AMPG can’t help but take risks — its management doesn’t know how to run machines. But these risks have enabled it to become a runaway success in its market.

Read MoreCNC Machine Shop Honored for Automation, Machine Monitoring

From cobots to machine monitoring, this Top Shop honoree shows that machining technology is about more than the machine tool.

Read More6 Machine Shop Essentials to Stay Competitive

If you want to streamline production and be competitive in the industry, you will need far more than a standard three-axis CNC mill or two-axis CNC lathe and a few measuring tools.

Read MoreWhere Micro-Laser Machining Is the Focus

A company that was once a consulting firm has become a successful micro-laser machine shop producing complex parts and features that most traditional CNC shops cannot machine.

Read MoreRead Next

Video: Minimizing Mistakes with Laser Scanning CMM

Die Tech & Engineering uses its scanning to CMM to avoid errors by inspecting electrodes prior to EDM.

Read More5 Rules of Thumb for Buying CNC Machine Tools

Use these tips to carefully plan your machine tool purchases and to avoid regretting your decision later.

Read MoreSetting Up the Building Blocks for a Digital Factory

Woodward Inc. spent over a year developing an API to connect machines to its digital factory. Caron Engineering’s MiConnect has cut most of this process while also granting the shop greater access to machine information.

Read More

.jpg;maxWidth=300;quality=90)