Toolholders

Widening Range Of Grooving Tools

Traditionally, a grooving tool grooves, a facing tool faces and, of course, special tools do special cuts. Improved insert manufacturing technology and toolholder design is changing this tradition, allowing specialized tooling to be used more generically in a wider variety of metalcutting applications.

Read MoreInspecting Tapers, Part 2: Toolholder Gaging

A few months ago, we discussed the calibration of conical taper masters, which are used to master taper gages. Now let's look at the parts those gages are used to inspect—toolholders.

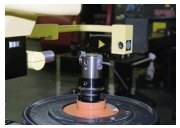

Read MoreCool Shrink Fit System

One of the neat things about metalworking is the wide variety of solutions generated for specific challenges. Shrink fit tooling is one such challenge. Much has been written and demonstrated about the advantages in concentricity, balance and ultimately accuracy that such tool-holders bring to the machining process.

Read MoreFour Toolholder Quality Factors

Toolholders are a critical link between the machine tool and the workpiece. This article looks at four fundamental toolholder manufacturing parameters that precision metalcutting shops need to consider when tooling for a job.

Read MoreSetting Tools Makes Small Shop Sense

Some people think tool presetting can be justified only in large operations. This Arizona shop shows how it makes sense almost anywhere.

Read MoreThe New Model For Short-Order Manufacturing

Through the combination of innovative process development, cellular manufacturing and quick setup procedures, this shop found a way to mix efficiency and flexibility in small-lot machining.

Read MoreSpindle System Has Dual Contact V-Taper

Most CNC machining centers use one of two spindle systems. The most common system is the solid V-taper. Gaining in popularity is the hollow shank or HSK-type spindle system.

Read MoreThermal Contraction Holds Tools Steady

When all is said and done, the intersection of a cutting tool and a workpiece is the point of metalworking. All process planning, employee training, capital investment and a host of other activities are links in a chain that lead to removing metal to make a part--chips.

Read MoreFive Key Concepts Of Modular, Quick-Change Tooling

A tooling system consisting of interchangeable cutting units and standardized locking units has a lot to offer users of CNC machines, whether for turning, milling, or both on a turn mill. These guidelines will help you think clearly about how modular, quick-change tooling can benefit your shop.

Read More

.png;maxWidth=300;quality=90)

.png;maxWidth=970;quality=90)