The New Model For Short-Order Manufacturing

Through the combination of innovative process development, cellular manufacturing and quick setup procedures, this shop found a way to mix efficiency and flexibility in small-lot machining.

Share

.png;maxWidth=45)

DMG MORI - Cincinnati

Featured Content

View More

When a manufacturer does as many things as well as Hartzell Propeller (Piqua, Ohio), it's hard to know where to begin to explain it all. Machining cells. Quick-change everything for rapid setup. Finely engineered processes through a widely and deeply engaged workforce. Superb tool control. And the list goes on.

But for our purposes here, maybe the most useful way to look at Hartzell's central manufacturing expertise is in their ability to get sound metalcutting processes up quickly on the table or in the chuck of a machine tool. That means getting processes right the very first time, and having them so well validated that subsequent setups can be executed in a few minutes. This critical ability allows the company to manufacture both extremely efficiently and in very small lot sizes with minimal inventory—keeping costs low and flexibility high. Moreover, as Hartzell has continued to move further down this track, they've been able to increase overall output while effecting major reductions in the scrap rate.

To make it all the more remarkable, this enviable performance level has been achieved by a manufacturer that, until three years ago, hadn't changed much in well over a decade. How has Hartzell done it? There's no magic to their methodology, just a clearheaded and persistent application of four important principles:

- They apply common machining platforms wherever possible so processes can be more readily optimized and are easily transferable throughout the shop.

- They rely on a small, carefully selected list of suppliers for technology support.

- They maintain excellent in-house process prove-out capabilities that are representative of, but not disruptive to, the production environment.

- They consistently apply the knowledge of their skilled machinists and inspectors to the critical tasks of process development and continuous improvement.

And maybe there's a fifth—collective common sense. Even though this shop does just about everything progressive manufacturers are supposed to do these days, it doesn't feel like a system driven by consultants or other so-called manufacturing experts. Rather, it seems simply like a lot of pretty smart people working together to do sensible things. There's nothing simple in that, of course, and nothing easy. It didn't happen overnight. But it did happen on purpose. Here's how Hartzell Propeller became a model of modern short-order manufacturing.

The Significant Emotional Event

While the corporate graveyards and acquisition lists are full of once-great company names that somehow lost their way, Hartzell is a notable exception. Oh, they have a rich heritage all right, but it's never been given up to anyone without an exclusive interest in aviation. Founded in 1917, the company's very first order—for wooden props—came from Orville and Wilbur Wright's company in nearby Dayton to fulfill a World War I government contract for biplanes. Since, Hartzell has done nothing but make aircraft propellers, though today the blades are fashioned from aluminum or graphite-and-Kevlar composite, and the hubs are machined from aluminum or steel. They can be found on airplanes with such well-known names as Beech, Dornier, Fairchild, Cessna, Piper and Shorts.

The historical core of Hartzell's business was in making two-blade propellers, which was once a good volume business and highly manageable from a manufacturing standpoint. Then about ten years ago, as the market for small airplanes was shrinking, company president Art Disbrow shifted the company focus toward developing higher technology propellers in three- to six-blade designs, and so continued the company's commercially successful track record based on an enhanced reputation for engineering excellence.

But as the company continued to build design muscle, it did little to upgrade its manufacturing expertise. The breaking point of that imbalance came three years ago when the realization sunk in that some components in Hartzell's newest, most innovative design were beyond the manufacturing capabilities of its own shop. While the company could easily justify having those parts made by outside suppliers, that proposition didn't sit well with manufacturing vice president Joe Brown and others in the plant. As much out of pride as anything, they resolved that Hartzell would not just build the capability to make those more challenging parts, but would transform itself into a world-class manufacturer tailored to the urgent business requirements for increased flexibility and quality, as well as the less-urgent desire to reduce costs.

And so Hartzell embarked on a journey of massive change. Single process departments were scrapped in favor of a cellular concept designed to produce families of parts complete in a short multi-process string. Operational quality responsibilities were shifted from the QC department to the machinists in the cells. Heavy investments were made in new, more capable CNC machining centers and turning centers, all fit with quick-change accessories such as pallet changers, quick-change chucks and quick change toolholders. And everyone in manufacturing became charged with the responsibility to participate both in the development of a completely new manufacturing methodology and with the ongoing process of continuous improvement.

That's not to say it was easy to learn to make parts in a new way. The basic groundwork for the implementation was laid over the last six months of 1993. They had the new system up first thing in 1994, and then spent the next three months struggling just to get back to their old level of output. But after another nine months of experience, "things really broke loose in '95," says Mr. Brown, as the company blasted through its old capacity limitations.

And thus Hartzell has changed virtually every aspect of its machining operation over the past three years, re-routing some 3,000 different parts over the course of the transition. But it's been worth it. Over that period, average lot sizes have dropped by 50 to 65 percent, and scrap rates have dropped even further, down more than 80 percent.

Cells And Standard Machining Platforms

The largest measure of these impressive performance gains can be found in the move to cells and in the "pre-engineering" of job setups for all the shop's newer CNC machines.

By "cell" we mean the close grouping of all machines necessary to produce a workpiece complete so that the entire processing sequence is compressed both in terms of space and time. Hartzell's first step was to rearrange all of its existing production equipment is this manner. The production machining was divided into six families of parts, and a cell was created for each.

Originally aimed at reducing leadtime and work-in-process inventory (since lots spend very little time in queue from one machine to the next), cellular manufacturing also speaks directly to other manufacturing control issues, such as quality. In Hartzell's case, machinists have an insight into the entire manufacturing process, and because each successive process step tends to quickly confirm the quality level of the preceding step, a problem and its source are much easier to identify. Cells also allowed Hartzell to get much better feedback on the true capabilities of their individual production machines. Says Mr. Brown, "When a machine is cutting anything and everything, it can be difficult to figure out just what it is capable of doing." If, however, the process domain is narrowed to a family of parts, the limitations of equipment become quite clear.

This clarity revealed the need for some more capable machining and turning equipment. Rather than spot-buying machine tools as they'd done in the past, the manufacturing team decided to take a much broader view on their acquisition of technology. The core of the idea was to establish common machining and turning platforms throughout the shop. This way, processes could be developed for a single machining environment, yet would be easily transferable from machine to machine. Because they would want to be able to run the same part program across multiple machines, controls would have to be common as well.

So the Hartzell manufacturing team decided to select a single source supplier for all their new machine tool purchases wherever possible, and then extended the same concept to two other critical classes of metalworking technology—quick-change workholding and handling equipment and cutting tools. Besides serving to standardize their machining environments, this method served to forge close working relationships with the key technology suppliers, which came to pay large dividends in process development. More on this later.

Hartzell chose Cincinnati Milacron (Cincinnati, Ohio) as their prime machine tool supplier, and today have Milacron Arrow, Sabre and Lancer vertical machining centers as well as Talon, Falcon and Avenger turning centers—all fit with Acramatic 850 or 2100 controls. SMW Systems (Santa Fe Springs, California) is the workholding supplier. All of the VMCs are fit with SMW's Setup-Switcher pallet system. Each workpiece of significant volume has a dedicated fixture and pallet combination that remains intact and that is stored right in the cell. This way, once the fixture location reference is established relative to the pallet, a repeat workpiece setup for that job requires only the time it takes to slide the pallet off of the storage rack and onto a lift cart, walk the cart over to the machine, and slide the pallet onto the changer and then into the machine. The whole sequence takes only a few minutes, most of which is still external to the setup. Moreover, this same job can be moved to any machining center in the shop on a moment's notice: same pallet system, same program.

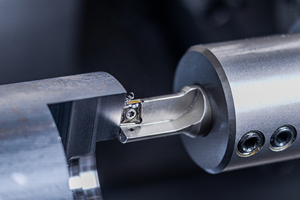

Turning centers are similarly configured. Each of the new turning centers is fit with an identical quick-change chuck, and custom-bored jaws are interchangeable across each machine. The turning centers are also all fit with KM quick-change tooling from Kennametal (Latrobe, Pennsylvania), Hartzell's primary cutting tool supplier. So turning setups can also be executed in minutes, and on any machine.

But the idea is not to continually move workpieces from cell to cell—that's really just for emergencies. The key concept is for the cell to run the same family of parts all the time, and be really good at it. So each cell is set up to run almost completely autonomously. Everything the team needs is there—all the cutting tools, gages, workholders, even the master part prints. While that might sound somewhat lavish in the sense that it requires greater redundancy of some tooling and gaging than is strictly necessary, Hartzell more than makes up the difference in increased output and quality, and in fact has achieved massive reductions in total cutting tool inventory through the finer appreciation of their true usage patterns.

Developing Processes

Six of Hartzell's cells "own" a part family; the seventh does not. Actually, it's not quite a cell in any conventional sense, at least not much of the time. They call it the toolroom mainly because it's an outgrowth of the shop's old fixture-making operation, an activity for which they have little time anymore. Today, it's more like a prototyping and process development lab that provides Hartzell the flexibility to serve its customers' and its own product development needs, as well as a production-like environment in which process improvements can be worked out without disrupting the daily flow of manufacturing.

Indeed, Hartzell has a comprehensive strategy for process development and continuous improvement that leverages a broad set of resources from inside and outside the company. Yet they have very little in the way of a formal engineering discipline, in fact no manufacturing engineers at all. Rather, they rely on the collective know-how of their skilled workforce supported by the technical knowledge of their suppliers.

As Mr. Brown puts it, "Process development is done by utilizing the best talent we have—inspectors and machinists." And the methodology is incredibly simple, with only minimal structure to the initial planning process. "We just get the appropriate people together and talk about the best way to do a job," says manufacturing services manager Bob Allenbaugh.

Once the Hartzell team has formulated a basic plan, they bring their vendors in to help determine the best machining practice, appropriate tools and process parameters. Some of this work is done off site. In cases where new machines are being purchased to execute a re-engineered process, the machinists go out to the supplier's facility to work out the process in detail. Because those responsible for production machining are intricately involved in the process planning, very little training is required once the machines are set in place on the shop floor. And Hartzell typically has those well-planned processes up and running within two weeks of the equipment arrival.

Other times, the process development will happen entirely in-house. This is made possible by the fact that Hartzell keeps both a production-ready machining center and turning center (a Milacron Arrow 500 and Avenger 250) functioning in the toolroom. This way, processes can be worked out on the very same level of equipment that is used in the cells, and then be directly transferred to production when they are ready. This allows Hartzell to analyze every aspect of a proposed process change before it is implemented—feeds and speeds, achievable tolerances, even real cycle times.

A good example of how Hartzell has put this capability to use can be found in the recent re-engineering of the steel hub machining process. The old process called for complete machining of the forging to get it to near net shape, then a heat treating operation, and finally an essentially redundant finishing process of milling, turning and grinding to true the part and achieve final dimensions. But by utilizing continuous improvement methods, the team developed a hard machining approach that shifted most of the machining work after heat treat. The theory was tested by toolroom and production machinists over a period of six months. The team ultimately delivered a production-ready process that allowed Hartzell to double its steel hub output within three months. Moreover, they actually achieved a 50 percent reduction in scrap during the implementation effort.

Even so, some observers might wonder about the cost effectiveness of relegating production-capable equipment to a toolroom. Here, Hartzell's standardization initiative pays huge dividends. Because the CNC milling and turning processes have already been engineered to be transferable from one machine to another, the toolroom can function as a production backup, and swing into that mode on a moment's notice. This capability has proved invaluable in allowing Hartzell the flexibility to respond to unscheduled surges in demand or unanticipated downtime on other production equipment.

A Word About Tool Control

While the cells and new machine tools and pallet systems will grab your attention as you walk through Hartzell's shop, a look into their tool cabinets tells an equally convincing story of how well this shop is under control. They are impeccably clean, complete and orderly. In fact, getting proper control of cutting tools was the final linchpin of the company's setup reduction initiative.

It was also one of the most challenging. Prior to the cells, Hartzell had a centralized tool crib with a full-time attendant plus another person who spent virtually all his time buying tools. With cells, the central crib was eliminated with each cell receiving a full complement of required tooling for its work. They began by assembling a rough list of what each cell would need, and then refined the inventory as they progressed.

Interestingly, they expected that there would be a major inventory reduction after the tooling was broken down to cells and excess or obsolete tools were identified. And they weren't disappointed. Indeed, the draw-down was so financially significant, it went a long way toward the purchase of the toolroom's two CNC machine tools. What they didn't expect, however, was that close attention to tool control would continue to pay dividends, and not just through the elimination of unanticipated stock-outs.

Tooling inventory is tracked closely through a networked inventory system from ITC Integrated Systems (Clayton, North Carolina). Each time a machinist removes an insert, he sweeps a reader over a bar code located right in the drawer, and the usage is automatically logged in the system. A reorder threshold is set for each expendable tool in the system, and thus purchasing is triggered automatically. Most important, it provides Mr. Allenbaugh with detailed information about the true tool consumption patterns, tied directly to the individual part families.

As Hartzell has come to understand more about their tool usage, they have continued to draw-down the inventory, with very significant reductions for two years in a row. According to Mr. Allenbaugh, the ultimate goal is to get down to a two-week supply of expendable tooling. Right now, they are running at about a month.

The Results

There are a myriad of ways that Hartzell can measure the success of their headlong rush into world-class manufacturing. As for quality, scrap rates have fallen precipitously since the change. In 1995 scrap was cut by 42 percent, in '96 by 39 percent, and this year it's down still another six percent.

As for responsiveness, consider these examples: While average aluminum propeller hub lot sizes have gone from 25 pieces down to about six, average leadtime has shrunk from 57 days to the current 22. Average steel hub lots have fallen from the previous 30 to the current four to eight, while the 60-day leadtime has shrunk to 25. On other more common parts, lot sizes have dropped from an average of about 500 pieces down to about 50. Across the board, Mr. Brown figures that they managed to boost the output-per-labor ratio by 50 percent even though they are on average executing three or four more setups a day on the CNC machines.

Another way to measure Hartzell's success is in the extraordinary achievements of its people. Remember, this was not a company in trouble, or with a desperate need to improve. This was a venerable manufacturer with a proud tradition, an excellent reputation, and by most accounts, a bright future. Still, the manufacturing team at Hartzell Propeller knew they could be better. And management provided the environment in which they could collectively express that desire.

Consider how much change was implemented in such a short period of time. That could only happen with the broad participation of a motivated workforce. And from the start, Hartzell's management team made sure that as many employees as possible would be actively engaged in the process. They began by forming a steering committee comprised of machinists, inspectors and some management. These are the people who collectively decided what the plan should be. Then a wider group of employees joined into the execution phase through local implementation teams that determined everything from how cells would be laid out to what kinds of equipment would be used and how processes would be re-engineered.

This proactive engagement of the workforce was the key. Because they were involved developing the plan they were naturally committed to seeing it be a success. "We had 88 people in manufacturing participate aggressively in the process of change," says Mr. Allenbaugh. "It took 88 people with a personal stake in the process to make this work."

Those people continue to serve as an inspiring model of how good a proud, determined manufacturing team can be.

Related Content

Big Daishowa Chuck Eliminates Chatter in Milling Operations

The Mega 12DS chuck is designed for trochoidal milling with anti-vibration end mills.

Read MoreHow to Mitigate Chatter to Boost Machining Rates

There are usually better solutions to chatter than just reducing the feed rate. Through vibration analysis, the chatter problem can be solved, enabling much higher metal removal rates, better quality and longer tool life.

Read MoreRego-Fix Toolholding System Reduces Coolant Consumption

MQL PG collets are designed for machines using one-channel, internal through-spindle MQL systems.

Read MoreCeratizit's Updated Tooling Solutions Improve Machining Performance

The company has upgraded its EcoCut indexable inserts lineup, as well as introduced two new toolholding and workholding solutions.

Read MoreRead Next

5 Rules of Thumb for Buying CNC Machine Tools

Use these tips to carefully plan your machine tool purchases and to avoid regretting your decision later.

Read MoreBuilding Out a Foundation for Student Machinists

Autodesk and Haas have teamed up to produce an introductory course for students that covers the basics of CAD, CAM and CNC while providing them with a portfolio part.

Read MoreRegistration Now Open for the Precision Machining Technology Show (PMTS) 2025

The precision machining industry’s premier event returns to Cleveland, OH, April 1-3.

Read More

.png;maxWidth=300;quality=90)

.jpg;maxWidth=300;quality=90)