Machining Centers

The Power of Practical Demonstrations and Projects

Practical work has served Bridgerland Technical College both in preparing its current students for manufacturing jobs and in appealing to new generations of potential machinists.

Read MoreUsing Automation to Reduce COGS and Stay Globally Competitive

Decade-long, multiphase automation investments lower operating costs and maintain technology lead in an increasingly competitive global market.

Read MoreTormach CNC Mill Minimizes Machining Vibrations

The 1500MX three-axis, servo-driven mill is said to enable 10 times the damping of cast iron, providing chatter-free cuts, superior surface finishes and 30% longer tool life.

Read MoreFryer VMCs Feature Handwheels for Manual Operation

Fryer vertical machining centers are designed for high-performance cutting, accuracy, reliability and ease of use.

Read MoreDigital Transparency in Machining Key to Multi-Site Additive Manufacturing

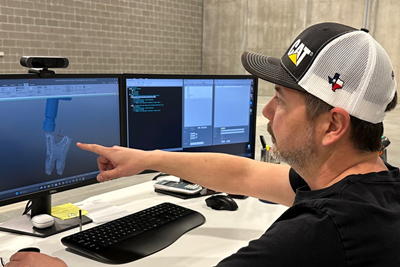

Cumberland Additive’s CNC programmer in Pennsylvania spends most of his time writing programs for machine tools in Texas.

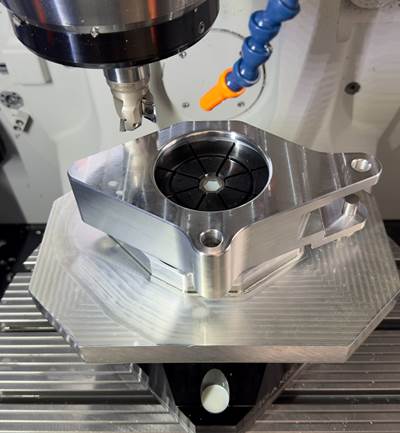

Read MoreShoulder Milling Cuts Racing Part's Cycle Time By Over 50%

Pairing a shoulder mill with a five-axis machine has cut costs and cycle times for one of TTI Machine’s parts, enabling it to support a niche racing community.

Read MoreThe Cut Scene: The Finer Details of Large-Format Machining

Small details and features can have an outsized impact on large parts, such as Barbco’s collapsible utility drill head.

Read MoreSoraluce Gantry Machines Handle Diverse Machining Applications

The new High Rail Gantry Machines offer high-speed cutting capabilities, high precision rates and the ability to handle high-volume machining tasks.

Read MoreBallbar Testing Benefits Low-Volume Manufacturing

Thanks to ballbar testing with a Renishaw QC20-W, the Autodesk Technology Centers now have more confidence in their machine tools.

Read MoreHow to Successfully Adopt Five-Axis Machining

While there are many changes to adopt when moving to five-axis, they all compliment the overall goal of better parts through less operations.

Read More

.jpg;maxWidth=300;quality=90)

.jpg;maxWidth=300;quality=90)