Machining Centers

CNC Machine Shop Honored for Automation, Machine Monitoring

From cobots to machine monitoring, this Top Shop honoree shows that machining technology is about more than the machine tool.

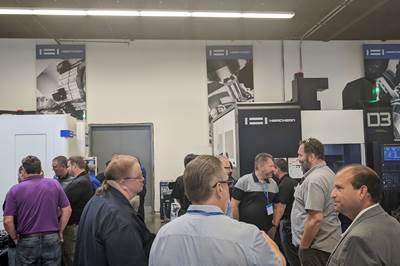

Read MoreOpen House Showcases Five-Axis Capabilities, Digital Tools

Five-axis machining technology was the highlight of the Hwacheon open house in Lincolnshire, Illinois this August.

Read More6 Machine Shop Essentials to Stay Competitive

If you want to streamline production and be competitive in the industry, you will need far more than a standard three-axis CNC mill or two-axis CNC lathe and a few measuring tools.

Read MoreChiron Compact Machining Center Provides Efficient Production

Westec 2023: The Micro5 five-axis machining center is designed for applications where delicate parts require autonomous machining with optimal surface quality.

Read MoreInverting Turning and Five-Axis Milling at Famar

Automation is only the tip of the iceberg for Famar, which also provides multitasking options for its vertical lathes and horizontal five-axis machine tools.

Read MoreWeingärtner Maschinenbau HMC Provides Stable Machining

The MPMC features a wide base, optimized guide ratio and configuration of the guideways to provide stability and prevent vibration during operation, even under extreme cutting conditions.

Read MoreHorizontal High-Speed Machining Saves Hundreds of Work Hours

High-speed machining is the latest change at Blair-HSM South, helping this once old-fashioned shop improve productivity and morale while enabling new work.

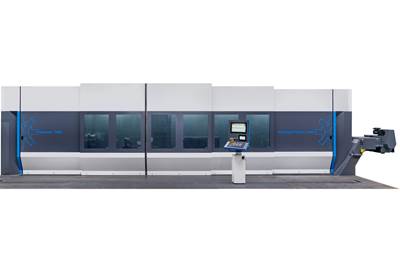

Read MoreRomi VMC Provides Enhanced Rigidity, Precision

The D 1250 VMC features linear roller guides that facilitate feed rates up to 1,575" per minute.

Read MoreHigh RPM Spindles: 5 Advantages for 5-axis CNC Machines

Explore five crucial ways equipping 5-axis CNC machines with Air Turbine Spindles® can achieve the speeds necessary to overcome manufacturing challenges.

WatchHow to Mitigate Chatter to Boost Machining Rates

There are usually better solutions to chatter than just reducing the feed rate. Through vibration analysis, the chatter problem can be solved, enabling much higher metal removal rates, better quality and longer tool life.

Watch

.jpg;maxWidth=300;quality=90)