Machining Centers

HMCs Designed For Flexibility

Heller’s full-color brochure features the MCH line of HMCs. a one-piece, cast iron construction and include Siemens 840D CNCs, swiveling pallet changers, rotary indexing tables and more.

Read MoreJob Shop-Developed Dovetail Fixture Takes Wing

Two aerospace job shops in California collaborated to produce a workholding fixture that allows any shop to set up a fully fixtured pallet dedicated to a five-axis job and then store the fixtured pallets for immediate use whenever the job repeats.

Read MoreVMC, HMC For Productive High Speed Machining

The FH400J is the company’s smallest HMC to date. Designed with a 15,000-rpm spindle, the machine is suited for high speed applications. The 2.

Read MoreEntry-Level Factory Automation Solution

The compact Kiwa-Japan KH-41 HMC is 60. 2" (1,530-mm) wide and can handle a variety of workpieces, providing an ideal entry-level factory automation solution, the company says. The HMC has a full rotary B axis and can be installed in the same space as a vertical machine.

Read MoreTwin-Table Machining Centers For Non-Stop Productivity

The TT series machining center features a twin-table design. While the tables operate on the same linear rail platform, each is controlled independently. This allows one table to machine parts within the enclosed work area while the other sits outside the enclosure for convenient loading and unloading.

Read MoreAutomated High-Speed Machining For Small-Part Manufacturing

The M8 is a five-axis, high speed machining center designed for manufacturing small parts, especially those requiring tight tolerances. The center can access five sides of a part to complete it in a single set-up. According to the company, the center is ideal for producing medical, aerospace and electro-mechanical components.

Read MoreToo Small To Touch

Hummingbird takes on machining work that is too small for most shops to handle. In fact, Hummingbird tries not to handle it either. To accurately machine the tiniest parts, this shop relies on processes that are as hands-off as possible.

Read MoreLittle Things Mean A Lot

The design of a machining center with the precision to mill tiny features illustrates what is (and is not) required for micromachining.

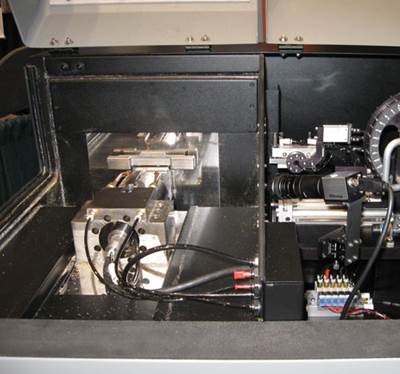

Read MoreA Micro Machine Design

This machine has no toolholders and no tombstone—but there is a camera. Here are details of a machining center designed for micromachining.

Read MoreVideo: Linear Motor Micromachining Center

Video shows the smooth, quiet, rapid motion characteristic of effective micromilling.

Read More