Little Things Mean A Lot

The design of a machining center with the precision to mill tiny features illustrates what is (and is not) required for micromachining.

Share

Takumi USA

Featured Content

View More

Hwacheon Machinery America, Inc.

Featured Content

View More“There is no magical technology that enables precise and effective micromachining,” says Gary Zurek. Instead, he says there is a mix of important considerations—any one of which might render the process incapable of holding tiny tolerances if it isn’t addressed appropriately.

He often refers to this as a “circle of technology,” because the circle doesn’t close unless all of the elements are in place.

Another way of describing this is that little things mean a lot.

Mr. Zurek is president and CEO of Kern Precision, the U.S. subsidiary of German machine tool builder Kern Micro- und Feinwerktechnik. Kern provides machining centers built specifically for making high-precision parts—work that isn’t limited to micromachining, but often involves the challenge of machining tiny features. Different Kern models hold part accuracies ranging from 10 microns down to 1 micron. Though the typical workpiece is small and light enough to be handled with human fingers, the machines themselves typically are not different in size from conventional machining centers—just different in design. The steps the builder has taken to address minute potential fluctuations in the process produce a rigid machine structure that does not scale down to the same extent that the workpieces do.

Maintaining fine precision also affects choices related to various components and accessories apart from the machine structure. Achieving a platform that is stable enough for both tiny milled features and fine precision at larger scales requires attention to sources of inaccuracy small enough that many machining center users don’t consider them.

Base Concerns

Those “minute potential fluctuations” that can compromise accuracy in micromachining are present in every machining process. It’s just that they can more easily be managed or ignored at the “macro” scale. They include vibration, machine deflection and temperature change. When a shop contemplates micromachining for the first time, it often discovers just how forgiving its full-size processes have been all along.

The Kern machines’ structure achieves stability in various ways. None of these elements are revolutionary, but each is essential to the design:

• C-frame construction. Mr. Zurek says this structure offers greater stiffness than bridge-type construction. In a C-frame design, the spindle is fixed except for the Z-axis motion. One drawback of the design, limited machine travels, is not necessarily a disadvantage when it comes to micro-scale work.

• Polymer concrete base. This choice produces a more massive machine than a typical frame made of cast iron or weldments. The concrete base not only further improves stiffness, but also inhibits vibration.

• Scale feedback. A typical ballscrew-driven machine tool measures the position of an axis using a rotary encoder, but the encoder can’t detect the influence of a change in the dimensions of the ballscrew itself. In addition to rotary encoders, the Kern machine also uses glass scale feedback with 100-nanometer resolution to

directly measure the actual axis position.

These considerations are integral to the machine design. However, some of the more accessible and seemingly secondary machine tool components also contribute to a repeatable process. These other elements are parts of the circle, too.

Tool Sensitivity

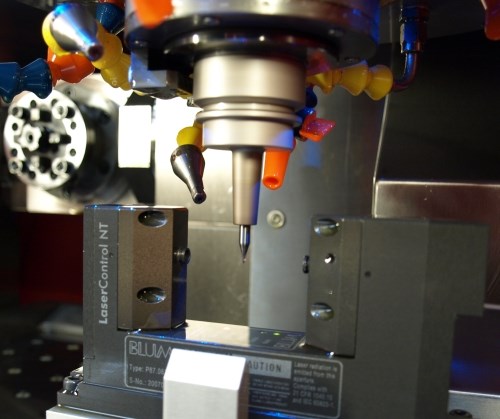

One of these is laser tool measurement. The Kern machines use an in-process laser tool measurement device from Blum. This accessory passes a laser beam between its two posts. The machine delivers the tool to the beam at the full spindle speed at which the tool will cut. That way, the system can measure the “actual” length and runout of the tool with all the dynamic and thermal effects in play.

Mr. Zurek says the accuracy of the machine is essential for using the device accurately. If a machine tool’s accuracy is prone to drift because of thermal growth or centrifugal effects of the spindle, then tool measurement even with a laser is not going to account for the change. He says the Blum unit simplifies the use of tools as small as 10 microns in diameter.

Part of the way the machine design keeps the tool position stable throughout the process is through an HSK interface. The alternative, tapered toolholders, are a poor fit for micromachining because centrifugal force from high spindle speeds tends to expand the spindle’s taper and reduce metal-to-metal contact, Mr. Zurek explains. Because the grippers that are part of HSK push out in the same direction as centrifugal force, the HSK system is better at keeping its clamp at high speeds.

Meanwhile, the coolant system deals with the influence of thermal effects. Coolant temperature is controlled to within 1 degree Celsius. One reason has already been suggested—ballscrews and other machine components change dimensions if the machine temperature changes. The micromachining process is sensitive to this expansion and contraction. However, another reason for keeping coolant temperature under control relates to a change that is even more potentially damaging. The tiny, delicate carbide tool is prone to break from seemingly small shocks to the process—shocks including a change in coolant temperature.

Other small shocks are also damaging, he says. For example, to avoid the impact of sudden changes in cutting force, one more element of the circle has to be considered—the NC code that is input to the machine.

Precise Code

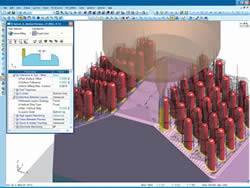

Not all shops recognize (or need to recognize) that their CAM systems may model workpiece forms and tool paths using a format that involves the STL algorithm. This efficient algorithm permits fast processing, and its sacrifice in faithfulness to the geometric model is slight. However, even a “slight” deviation in a contoured tool path in micromachining—and the corresponding increase in material engagement—can produce an increase in load that is sufficient to break a tiny tool, Mr. Zurek says. For this reason, another necessary part of the micromachining process is likely to be a CAM system that generates extremely fine-detail tool paths.

All of the above considerations don’t comprise a complete list, but together they illustrate something significant about both the micro machine tool and the micromachining process. That is: Micromachining does not call for a change in technology as much as a change in attention and discipline. That attention and discipline apply to the machine tool design, and they must apply to the way the machine tool is used as well. Succeeding at micromachining involves a commitment to consistently focusing on variables in the process that were always there, but might never have merited such awareness and scrutiny before.

Related Content

Orthopedic Event Discusses Manufacturing Strategies

At the seminar, representatives from multiple companies discussed strategies for making orthopedic devices accurately and efficiently.

Read MoreQuick-Change Tool Heads Reduce Setup on Swiss-Type Turning Centers

This new quick-change tooling system enables shops to get more production from their Swiss turning centers through reduced tool setup time and matches the performance of a solid tool.

Read MoreInside the Premium Machine Shop Making Fasteners

AMPG can’t help but take risks — its management doesn’t know how to run machines. But these risks have enabled it to become a runaway success in its market.

Read MoreThe Future of High Feed Milling in Modern Manufacturing

Achieve higher metal removal rates and enhanced predictability with ISCAR’s advanced high-feed milling tools — optimized for today’s competitive global market.

Read MoreRead Next

CAD/CAM Considerations For Micromilling

Milling with tools that are smaller than 100 microns in diameter presents equipment design and toolpath-generation challenges. This NC software maker offers strategies for creating safe, optimized tool paths for micromilling.

Read MoreRegistration Now Open for the Precision Machining Technology Show (PMTS) 2025

The precision machining industry’s premier event returns to Cleveland, OH, April 1-3.

Read MoreBuilding Out a Foundation for Student Machinists

Autodesk and Haas have teamed up to produce an introductory course for students that covers the basics of CAD, CAM and CNC while providing them with a portfolio part.

Read More