Machining Centers

Compact HMC For High Speed Machining

Toyoda says its small, economical FH400J is designed with a 15,000-rpm spindle and is well-suited for high speed applications. The HMC’s work area measures 23.

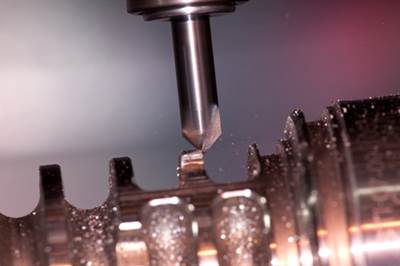

Read MoreLooking At 30-Tapers In A New Light

The six 30-taper machine tools in one Northeastern shop are used for more than just drilling holes and performing secondary operations. The small-footprint equipment is also used to machine parts complete from titanium and other challenging materials.

Read MoreRange Of Machines For Complex, Precision Parts

To respond to the requirements of the medical, dental, watchmaking, aerospace and micro-technology industries, Willemin-Macodel offers a range of precision, high-performance machining centers designed for complex parts and quality surface finishes. The company will showcase the capabilities of these models via machining demonstrations involving various types of components.

Read MoreHigh-Capacity, Bed-Type Milling Machine

Knuth Machine Tools’ KB series bed-type milling machines are equipped with large beds and wide columns for handling large parts. The machine design provides increased stability, low vibration and improved precision at high table loads, the company says.

Read MoreBridge Mill Tackles High Speed Net-Shape Machining

The Hi-Net DMC-900HN by Johnford is suited for aerospace manufacturers and mold/die shops that need speed, rigidity and precision in a competitively priced double-column machining center. Absolute Machine Tools, Inc.

Read MoreHow to Improve Machining Center Accuracy

Accuracy is not just inherent to the machine—it also depends on how the machine is used. Try these techniques to let a new or existing CNC machining center achieve its potential precision.

Read MoreTurning On A Machining Center

VIDEO. Part of Renishaw’s automated production process, this turning operation uses tools affixed to the machining center’s table while the workpiece is mounted in the spindle.

WatchVideo: Automatic Part Verification Through Reference Comparison

The machining center in this automated production process inspects its own work and updates its own positioning. Probing a known, traceable reference makes this possible.

WatchThe Big Niche

Expertise and the right equipment for machining large components for oilfield and other industries enable this shop to succeed despite fluctuating economic conditions.

Read MoreFlexible Production Center

Porta says its Multicenter machining cell is suited for production of high volume parts, but also of small/medium batches requiring frequent tooling/fixture changes. Essentially, the center groups CNC machining units around a pallet indexing table, which presents each pallet to the units sequentially.

Read More