Machining Centers

Honing On A Horizontal Machining Center

A specially designed tooling package for honing operations, along with live, on-board gaging, allows critical honing operations to move to HMCs, thereby eliminating several separate steps on multiple dedicated machines.

Read MoreShifting Gears To Integral Drive Adds Productivity

Machines with geared-head spindles are typically employed for machining titanium and other tough materials that require high torque. However, replacing such models with integral-drive HMCs from Makino has enabled this contract manufacturer to significantly improve productivity on time-sensitive aerospace jobs.

Read MoreAluminum Molds In Three Weeks Or Less

While aluminum molds are commonly used to create prototypes or to serve as stopgap bridge tooling, they are starting to receive greater attention for production work. This shop’s approach to creating aluminum molds in one day to three weeks is the same for each of these situations.

WatchFive-Axis Jig Borer For Die, Mold Manufacturing

Designed for high-precision die and mold machining, Yasda’s YBM-Vi40 five-axis jig borer is said to reduce machining time of complicated shapes in extremely hard materials. The jig borer can tilt the workpiece to reduce cutter length requirements, which enables feed rates of 2,000 mm/min.

Read MoreHMC Designed For Big Parts

Doosan’s HM1250 HMC machines parts measuring 78. 8" in diameter and 67.

Read MoreFive-Axis Machines Feature Multi-Process Capability

Designed for small-lot production of complex parts, Methods Machine Tools’ Matsuura five-axis VMCs feature Cublex technology. This technology integrates turning and grinding functions into a single, high-performance milling platform to deliver speed, power, accuracy, increased tool capacity and multi-process machining capabilities, the company says.

Read MoreProbing for Part Inspection and Crash Avoidance

A reader uses “Ask an Expert” to explore various potential uses of the machining center’s probe.

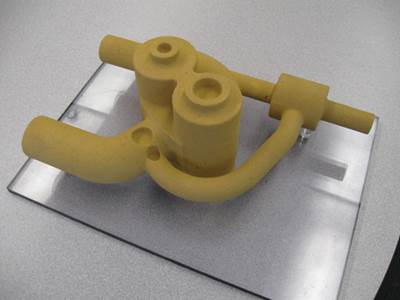

Read MoreStraight to Sand

Through direct CNC machining of molds and cores, this supplier of cast and machined parts skips the pattern-making step that would otherwise be fundamental to casting. The result is weeks of lead-time savings for complex parts that are needed in a hurry.

WatchCNC Machining As A Prototyping Technology

Designcraft has many more machining centers than additive devices. Here is why.

Read MoreCutting Spiral Bevel Gears On A Five-Axis Machining Center

To produce high-precision ring gears in low- to mid-volumes, an emerging option is the use of five-axis machining centers. Mitsui Seiki CNC vertical and horizontal machining centers are being used in this application.

Read More