Machines

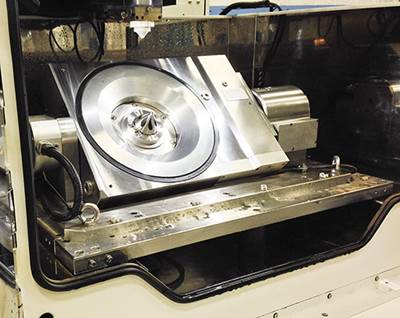

Internal Cylindrical Grinding Machine Accommodates Longer Workpieces

Available from United Grinding, the Studer S141 universal internal diameter (ID) cylindrical grinding machine enables internal grinding of longer workpieces such as those used in the machine tool, drive element, aerospace and toolmaking industries.

Read MoreVitrified Grinding Wheels for Centerless Grinding

Available from Fives, Gardner Abrasives vitrified grinding wheels are designed for efficient centerless grinding operations.

Read MoreCrankshaft Grinder Equipped with Twin Grinding Heads

Emag’s PMD 2 crankshaft grinder incorporates the company’s Naxos-Union technology and is said to provide high output rates.

Read MoreVertical Turning Centers Accommodate Large, Asymmetrical Workpieces

The Yama Seiki GV-1 series vertical turning centers offer heavy-duty cutting capabilities to complete turning, milling, contour milling and drilling applications on one machine.

Read MoreA Hollow-Access Unit for Wire EDM

By simultaneously rotating and tilting the workpiece, this rotary tilt/turn hollow-access device from Hirschmann enables the EDM wire to cut complex openings that may have different paths at the top and bottom of the opening.

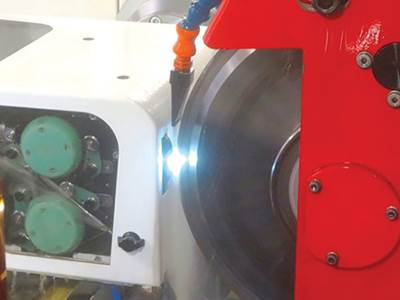

Read MoreWire EDM for Dressing Metal-Bonded Wheels

The Studer WireDress system, which uses the wire “spark erosion process” to dress a metal-bonded grinding wheel while it is still mounted in the grinder, makes using these wheels more efficient and economical.

Read MoreGetting in Touch with Optimal EDM Results

Makino’s Hyper i control for wire EDM uses touchscreen navigation in its user interface, which helps a basic user to match the productivity and capability of an experienced operator.

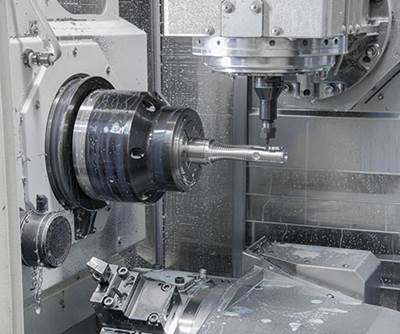

Read MoreMultitasking Lathe Machines Complex Aerospace Workpieces

The six-axis Ganesh Cyclone 78-MYS twin-spindle, single-turret multitasking lathe is designed to get complex work done efficiently in a single operation.

Read MoreMaking it in Medical

Here are the challenges that modern medical machine shops face and how they have helped shape this shop in particular.

Read MoreSinker EDMs Enable Zero-Electrode Wear

Sodick’s AD series of sinker EDMs includes the AD35L and the AD55L high-performance models.

Read More