Machines

Cylindrical Grinding Technology in Motion

United Grinding's annual Motion Meeting in Thun, Switzerland, highlights the group’s latest developments in cylindrical grinding. News from this year’s event includes the introduction of new models that broaden the range of ID and OD cylindrical grinding in the Studer line.

Read MoreSwiss-Type Lathes Finish Small Workpieces in One Setup

Yama Seiki’s SW series Swiss-type lathes are designed to accommodate workpieces smaller than 42 mm (1.65").

Read MoreMulti-Axis Workholding System Uses Three-Side Dovetail

The Get-A-Grip pedestal fixture for five-axis workholding uses a triangular clamping geometry for the matching workpiece and clamping dovetails.

Read MoreWire EDM for Jet Engine “Fir Trees”

Advances in wire EDM (electrical discharge machining) technology have made it acceptable for machining critical aerospace parts. It may now become the preferred method for cutting turbine disc “fir trees,” a particularly demanding application that highlights the benefits of this machining process.

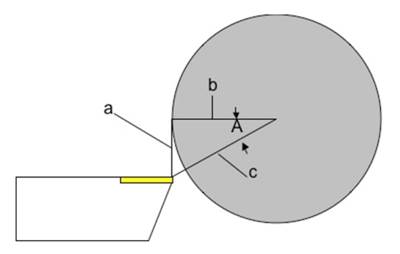

Read MoreMind the Tool Center Height When Turning Small Diameters

Let’s use the Pythagorean Theorem to see how small, turned diameters can vary from nominal when your lathe’s tool center height is off.

Read MorePlasma Cutters Automatically Maintain Torch Height

Techno CNC Systems’ HPLC plasma cutter series offers machines for small- to mid-sized shops and classrooms.

Read MoreVMC Offers Large Work Envelope within Compact Design

Kitamura Machinery’s high-capacity Mycenter-3XD vertical machining center is designed to save space while offering a larger work envelope.

Read MoreLarge Machines and Capacity in Renovated Pfronten Facility

DMG MORI hosted its 20th open house earlier this month in Pfronten, Germany. The event featured 76 machine tool exhibits, including four world premieres, and nearly 8,800 attendees had the opportunity to tour the recently renovated and expanded facility to see its latest machine tool technologies. Here are some observations from the event:

Read MoreThree-Axis VMC Enables Continuous Small Part Production

Designed for high productivity, Mazak’s Vertical Center Universal (VCU) 500A is a small-footprint, three-axis machining center capable of processing workpieces ranging to 19.68" × 19.68" × 9.84".

Read MoreVMC Increases Stability with Slideways

DMG MORI’s NVX 5100 vertical machining center is designed to promote machining efficiency with high spindle speeds, and increased stability and vibration damping through the use of slideways.

Read More

.jpg;maxWidth=970;quality=90)