Holemaking

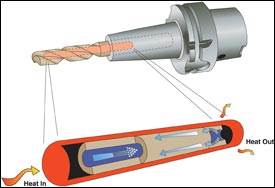

Drilling Dry With A Heat Pipe

It's widely known that hole making is, by a significant margin, the most frequently performed process among metalworking operations. It's also among the most difficult operations to control from a thermal perspective.

Read MoreAnother Way To Square—Or Is It Perpendicular?—It Up

There are a number of tools available for shop personnel to evaluate the right angle relationship between two surfaces. The basic machinist square has a number of variations, the most common being the hardened steel square used to check right angles and set up milling and drilling machines.

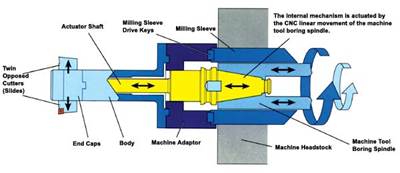

Read MoreA Boring System For Non-Round Holes

Machining an out-of-round bore is easy if you're not particular about the location or magnitude of the roundness error. But accurately machining a hole that has a precisely defined non-round profile is a capability that would seem to be well beyond what a standard boring bar can accomplish.

Read MoreCMM Locks In Inspection And Productivity

This company, established more than 140 years ago, manufactures a high volume of brass padlocks annually. They are made on two large rotary transfer machines with drilling capabilities. The company is also doing reverse engineering for tooling purposes for other machines it uses in its manufacturing and assembly departments.

Read MoreTooling Reduces 21 Minute Job To 9 Minutes

Shop leadership was looking for a way to reduce the time it took to complete a very difficult boring job. The job took 21 minutes per part to complete with multiple roughing and finishing processes. It required 10 minutes of hone time.

Read MoreBoring Bar Adjusts In The Cut

Firms that do a lot of boring of gear boxes, valves, castings and other complex components on horizontal boring mills, floor-type boring mills and similar horizontal-spindle machines should be interested in Controlled Boring Bars and Contouring Heads.

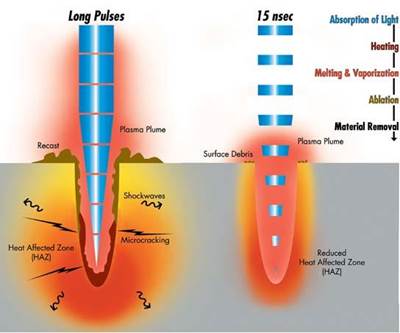

Read MoreNon-Traditional Methods For Making Small Holes

Consider these alternatives when conventional drilling can't do the job.

Read MoreThe Role Of Balance In High Speed Finish Boring

Precision boring is particularly vulnerable to unbalance, but not every high speed boring application demands a balanceable tool.

Read MoreGood Planning Makes Better Threaded Holes

Hole making is as common an operation as exists in metalworking. Tapping those holes is also very common. Finding a way to get quality threads and using efficient processing are ongoing jobs for this Indiana shop.

Read MoreCompany Invests In HMC To Keep Pace With Growth

Since its installation, this HMC has dramatically reduced floor-to-floor times on the manufacture of precision reamers, which are used for expanding oil well bore holes during directional drilling operations.

Read More

.png;maxWidth=300;quality=90)