Holemaking

Small-Diameter Drilling Under Scrutiny

Today's smooth-running high rpm spindles not only allow shops to cut faster with standard tool designs, they also unlock the potential of tiny tools.

Read MoreA Better Process For Hole Making

This company is in the business of drilling millions of holes in very large parts. As an established manufacturer of heat exchangers and components, the Calgary, Alberta-based company drills an estimated 1.5 million holes per year in metal plates.

Read MoreManufacturer Halves Cycle Times With Machining Center

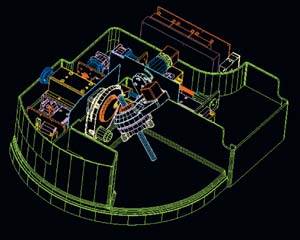

The complex shapes of the iron castings that make up the housings for this company's flow meters require machining on multiple faces. The castings undergo various types of machining operations, from drilling to helical thread milling.

Read MoreOne Stop Milling, Drilling, Turning And Grinding

Many shops, in an effort to reduce the handling of workpieces and get takt times (time spent in the cut) as low as possible, are looking to streamline this traditional hurry-up-and-wait process scheme.

Read MoreBore Gaging Flexibility Boosts Productivity

A key machining operation at the plant is the boring of metal; consequently, improved inner and outer diameter measurement ability is required.

Read MoreDrilling Deep Holes On A VMC

The recipe for best results is simple: Start with a rigid machine, add a high pressure through-the-spindle coolant system, then combine these with the right drill geometry plus the right speeds and feeds.

Read MoreThe Dynamics Of Better Drilling

Vibration is at the heart of a variety of common problems in machining holes. Mathematical analysis is helping to bring about a better understanding of hole-making processes...including how these vibrations behave, and what steps to take to bring them under control.

Read MoreReclaiming The Hole-making Process

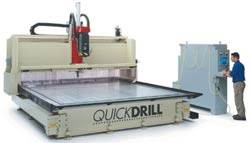

A shop that had been farming out hole-making operations on oversized components brought this work back in-house after acquiring a large-format, CNC drilling machine. The process now can be done more quickly, at lower costs and on schedule, with many workpieces machined as assemblies instead of separate pieces

Read MoreMulti-Axis Drill Sharpening Made Easy

Today, metalworking is privy to some very remarkable performances by the combination of things mechanical and things electronic--mechtronics. We've seen the reality of lights out shift operations. Programming systems that make what was state of the art 5 years ago seem like writing with a hammer and chisel. An example of the melding of mechtronics is this new drill sharpening system.

Read MoreRetooling Saves Time And Space

Fermer Precision machines a variety of precision parts from aluminum, cast iron, powdered metal, carbon steel and low-carbon steel for automobiles, firearms, medical products and train brake systems. The company relies on a Mori Seiki SV-500 and two OKK KVC 600 vertical machining centers for drilling, reaming and chamfering operations.

Read More

.png;maxWidth=300;quality=90)