EDM

EDM Solution Accommodates Tall Workpieces

The FA30V Advance wire EDM from MC Machinery Systems accommodates tall workpieces for large-part manufacturers.

Read MoreA Novel EDM Application

GF AgieCharmilles designed the FO 550 SP die-sinking EDM, the company probably never imagined it would be used like this.

Read MoreEDM, Metrology System Pairing Opens New Doors

Seeking a solution for producing and measuring smaller, more intricate parts, this shop combined a ram EDM unit and optical 3D metrology system. Each provided significant benefits on its own, but the pairing of the two technologies enabled the company to achieve new levels of precision and productivity.

Read MoreSpark Control Pushes Wire EDM Boundaries

Precisely controlling and monitoring each individual spark enables this wire EDM machine to cut hardened, high-temperature alloys with high precision.

Read MoreEDM, Five-Axis Milling Technologies

The CUT 200 wire EDM is designed to provide faster spark-to-spark wire threading, increase energy efficiency and boost productivity when cutting parts of variable heights.

Read MoreEDM and Complementary Technologies

The company’s offering of EDM, hole popper and waterjet technologies includes the FA10S Advance wire EDM, the EA12V sinker EDM, the ED2000M small-hole EDM drill and the DX44 waterjet. The FA10S Advance wire EDM features the company’s M700 series control.

Read MoreHigh Speed Wire and Sinker EDM

The AG40L sinker EDM with linear motor drives offers high speed and high acceleration, which is said to enable an even and natural flushing condition for high part accuracy.

Read MoreSpecial High-Temp Alloys Spark Interest in EDM

Today’s wire EDM technology preserves the surface integrity of proprietary titanium alloys and other high-temperature materials, so aerospace and medical applications using this process are booming.

Read MoreWire Rethreader Hits The Mark

The rethreading system on a wire electrical discharge machine helps a U.S. manufacturer keep up with production requirements for a critical pistol component.

Read MoreEDM Energy Conservation Without the Effort

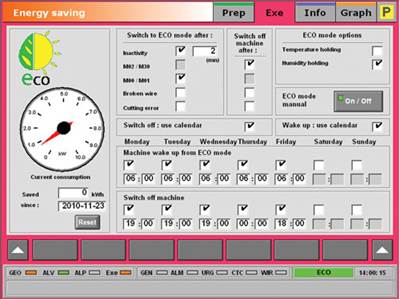

Most machine tool energy conservation systems simply track power consumption, placing the burden of actually reducing energy use on manufacturers. GF AgieCharmilles aims to change that with the EconoWatt II, an automated system for wire EDM.

Read More

.jpg;maxWidth=300;quality=90)