Special High-Temp Alloys Spark Interest in EDM

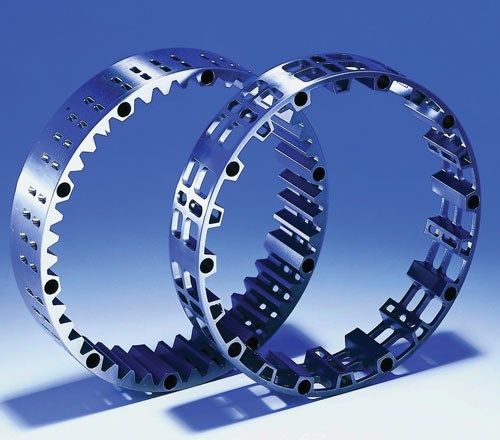

Today’s wire EDM technology preserves the surface integrity of proprietary titanium alloys and other high-temperature materials, so aerospace and medical applications using this process are booming.

Share

At IMTS 2010, top officials for the U.S. arm of GF AgieCharmilles (Lincolnshire, Illinois) talked to the trade press about trends in applications for electrical discharge machining (EDM), which is one of the company’s product specialties. One of the most significant of these trends is growing use of wire EDM for aerospace and medical components that were once off-limits for this machining process. We asked the company to tell us more about this trend and what was behind it. Here is a summary of these findings.

Today’s high-temperature alloys are being used in the manufacturing of a new generation of parts for aerospace, medical and other industries, but conventional machining methods are struggling to cope with these materials. That’s because many manufacturers are having special, proprietary “blends” of these alloys developed to their own specifications for their particular applications. The value of these alloys is so important that details about them are tightly held secrets and information about specific applications is rarely shared.

However, what is known is that these special blends are often harder and tougher than their commercially available counterparts and, in many instances, are either impossible or extremely costly to cut using conventional machining processes. So, many manufacturers working with these materials have been exploring other, non-conventional machining methods. Wire EDM, in particular, is garnering renewed attention.

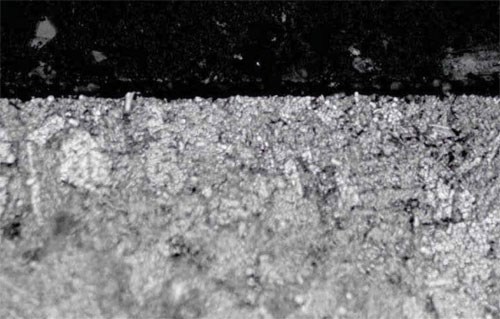

In the late 1990s and early 2000s, the use of Inconel, titanium and high-temperature alloys increased dramatically, especially in the aerospace and medical industries. However, wire EDM never won wide acceptance as a process of choice for cutting these materials, mainly because of concerns about surface imperfections in the finished part. The EDM technology of those days often caused surface bluing (an effect of oxidation), micro-cracks and surface cracking, in addition to the formation of a so-called white layer.

The white layer consists of microscopically thin sublayers of the workpiece material that have been metallurgically changed by the highly localized but intense heat of the EDM process. The material in this “heat affected zone” is usually hardened and may exist in an almost crystalline state. Once the part is in service, the white layer can easily flake off, leading to micro-cracking and eventually part failure.

Micro-cracking in high-temp alloy workpieces also results from the heat of the EDM process. In addition to micro-cracks that can degrade part surface integrity, EDM can cause surface cracks (“lines”) and other cosmetic imperfections. Although the process was still significantly more accurate than the conventional machining methods being used at that time, concerns about EDMed surfaces caused it to be rejected from many applications. See the sidebar on the opposite page.

Generators to the Rescue

The development of anti-electrolysis power generator technology in the late 1990s allayed most of the concerns about the cosmetic appearance of parts cut with EDM, especially the persistent objections to bluing. Bluing, an unsightly discoloration of the workpiece surface, is caused by a chemical reaction between certain metal ions and the dielectric water in the presence of an electrical current. Essentially, it is a form of oxidation, or rust. Although anti-electrolysis has virtually eliminated this problem, this technology tends to fall short when it comes to the special high-temp alloy blends currently being developed. Fortunately, the introduction of digital power generators has bridged the gap.

One of the most important features of the digital power generator for wire EDM is the ability to “tune” it for specific materials, including proprietary blends of high-temp alloys. The digital power generator developed by GF AgieCharmilles, for example, is called Intelligent Power Generation (IPG). Other EDM builders have also developed digital power generators. All seek to take advantage of advances in high speed, digital data processing on microchips embedded in the electronic circuitry of the power generator. However, the performance and capability of these systems vary. For example, the software algorithms that run the calculations in the microprocessors are proprietary. Naturally, each builder offers competing claims about its system’s superiority. End users must discern for themselves which represents the best value. A critical factor for aerospace and medical manufacturers, however, is how effectively the generator can be “tuned.”

The GF AgieCharmilles IPG is representative of power generators with this capability. It is designed to accommodate a wide range of wire EDM systems and provides a high degree of precision associated with perfect surface quality. This digital generator controls the energy of each spark to produce surface finishes as fine as Ra 0.05 micron (2 microinches). Typically, once a generator is tuned to a particular material blend, a shop will use only that wire machine to process that material.

Tuning a digital generator can be quite a challenge because today’s proprietary high-temp alloy blends are often very similar to one another, yet require different generator adjustments to optimize cutting. GF AgieCharmilles has formed a team of experts that conducts test cuts, evaluates the results and determines the exact generator settings for the fastest possible cutting without causing micro-cracking or other workpiece surface imperfections.

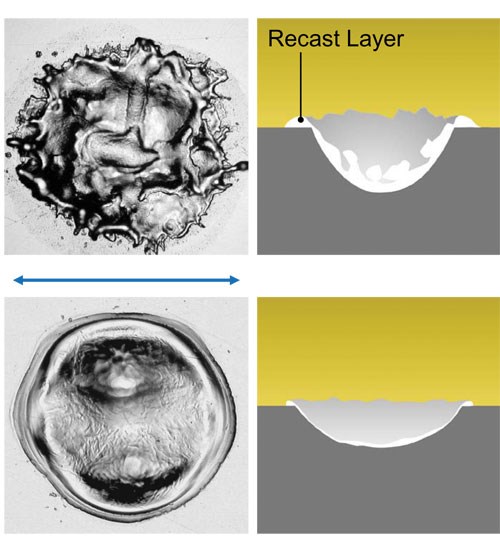

The essence of this research is to control the heat produced by the EDM process. This calls for a subtle balance. EDM uses the heat of a highly localized transfer of electrical energy (the “spark”) between the electrode and the workpiece to literally boil away a microscopic bit of the workpiece material. This process enables EDM to cut hard, tough materials more efficiently than conventional machining processes. However, unless heat is carefully controlled, it can reach excessive levels that leave unwanted conditions on the workpiece surface.

With digital generator tuning, EDM builders can achieve an optimized balance by precisely changing the properties of the wire EDM spark—how it occurs, its shape and its wavelength. These generators allow builders to shorten the time a wire EDM spark occurs, yet maintain the necessary heat intensity to cut.

Typically, this is achieved when spark pulses are more intense, and the on/off cycles are shorter. The duration of these more intense sparks is so brief that little or no heat penetrates the workpiece to cause micro-cracks or create a white layer. According to an independent report on GF AgieCharmilles’ generator, white layers were non-existent on high-temp alloy test parts even after researchers performed four skim passes.

Tips for High-Temp Alloys

Through years of experience, EDM builders have identified helpful practices and tips for wire cutting high-temp alloys. While there are no charts of established parameters for cutting specially blended alloys, settings and procedures recommended for standard high-temp alloys are a good starting point. These include choices for variables in the dielectric water, electrode wire type and features of the machine.

When cutting high-temp alloys, shops should take steps to minimize the transfer of heat to the workpiece. One way to accomplish that is by keeping dielectric water in the machine chilled. A chiller capable of holding water temperature to ± 1° Celsius should be considered a requirement for wire cutting high-temp alloys.

However, caution should be taken when measuring finished parts because lowering the temperature of the part during cutting may produce results that change significantly when the part returns to the shop atmosphere. This can be a serious issue with some high-temp alloys.

To further avoid transferring heat to the workpiece, the conductivity of the dielectric water should be adjusted to levels that enable reducing the distance, or gap, between the wire electrode and the workpiece. Basically, the levels of conductivity that apply to cutting grades of carbide are a good starting point for high-temp alloys. Here’s the simple explanation: Decreasing conductivity means that the optimal level of electrical resistance between the electrode and workpiece can be achieved with a very small gap between them. Under these conditions, less energy is required to overcome the resistance to form a spark. In short, less energy means less heat for the same work.

Because high-temp alloys are so hard, GF AgieCharmilles and other EDM builders recommend coated, or even double-coated, electrode wire. Compared to plain brass, coated wire enables better control of spark formation. This makes it easier to create a more intense spark that efficiently cuts high-temp alloys, yet does not penetrate into the material’s surface.

An example of a wire appropriate for cutting high-temp alloys is GF AgieCharmilles’ AC SW-A; which consists of a brass wire core surrounded by a zinc coating. According to the company, AC SW-A is particularly suited to machining complex parts that require the wire to cut at angles greater than 10 degrees.

In general, coated electrode wires like this one are able to transmit a higher voltage from the power generator because they withstand the heat produced while electrical energy is discharged as sparks. The coating is “sacrificial.” It is designed to melt away at a relatively low temperature, thus absorbing and carrying away heat that would otherwise affect the strength of the brass core. (Physicists refer to this effect as the latent heat of vaporization). This enables the coated wire to cut more efficiently while resisting breakage and keeping the workpiece cool.

Using solid brass wire for high-temp alloys has another drawback: the possibility of re-plating. During the cut, some of the brass can melt away and re-solidify onto the workpiece surface. Removing this brass layer from part surfaces may entail a costly cleaning process. If not removed, the thin layer of re-plated brass can cause false part size measurements. When the part is in service at elevated temperatures, the re-plated brass may melt away, thus leaving the part undersized.

Wire EDM units that will be used for cutting high-temp alloys must have long-lasting precision and accuracy. In industries such as aerospace and medical, wire machines are expected to run around the clock. Cycle times exceeding more than 50 hours are not uncommon. Machines working under these conditions must be sturdy and durable. It is recommended that they also have remote notification capabilities for process monitoring and/or accountability. This feature enables the machine to send a message wirelessly to a cell phone or an Internet-based messaging system such as an e-mail network.

It’s Only Going to Get Tougher

The trend in material science is to develop materials with greater strength, less weight, and better resistance to heat and corrosion. Shops with the know-how and equipment to process these new materials will be well positioned to win contracts for parts designed around their properties. Given its flexibility and capability, wire EDM will undoubtedly be an essential machining resource in these applications.

Related Content

AFRC, ATI Partner to Boost Aerospace Materials Innovation

ATI Inc. has joined the University of Strathclyde’s AFRC as a tier one member, aiming to develop metallic alloys that support sustainability in the aerospace sector.

Read MoreSolar Atmospheres Receives Northrop Grumman Approval for South Carolina Facility

All five Solar Atmospheres facilities are now an option for customers with Northrop Grumman requirements for vacuum heat treating.

Read MoreIncreasing OEM Visibility to Shopfloor Operations for the Win

A former employee of General Motors and Tesla talks about the issues that led to shutdowns on factory lines, and what small- to medium-sized manufacturers can do today to win business from large OEMs.

Read MoreArch Cutting Tools Acquires Custom Carbide Cutter Inc.

The acquisition adds Custom Carbide Cutter’s experience with specialty carbide micro tools and high-performance burrs to Arch Cutting Tool’s portfolio.

Read MoreRead Next

5 Rules of Thumb for Buying CNC Machine Tools

Use these tips to carefully plan your machine tool purchases and to avoid regretting your decision later.

Read MoreRegistration Now Open for the Precision Machining Technology Show (PMTS) 2025

The precision machining industry’s premier event returns to Cleveland, OH, April 1-3.

Read MoreSetting Up the Building Blocks for a Digital Factory

Woodward Inc. spent over a year developing an API to connect machines to its digital factory. Caron Engineering’s MiConnect has cut most of this process while also granting the shop greater access to machine information.

Read More

.jpg;maxWidth=300;quality=90)