EDM

Job Shop Uses 3D Wire Bending and CNC Machining To Find Its Niche

Marshall Manufacturing melds CNC machining and 3D bending to create intricate medical components from small-diameter barstock and tubing. Customer needs spurred the shop to carve out what has become a successful medical-manufacturing niche.

Read MoreWire EDM Offers Speed, Accuracy

The AccuteX AX-1165 EDM from Absolute is a heavy-duty wire machine that accommodates workpieces weighing as much as 9,000 lbs.

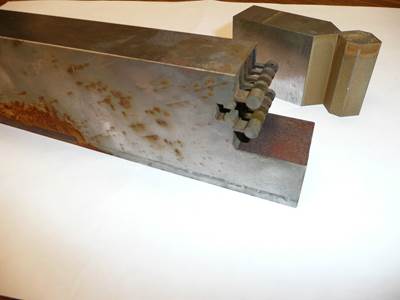

Read MoreTips for Controlling Oxidation and Pitting on a Wire EDM

Additives, machine settings, workpiece materials and current technology are factors in avoiding common problems with unwanted rust and surface defects.

Read MoreWire EDM Improves Throughput, Surface Finish

This manufacturer insulates itself from global competitors by focusing on high-quality products across a range of industries. Just as important, however, is routine investment in new technology. The company’s latest acquisition, the AC Progress VP2 wire EDM from GF AgieCharmilles, has significantly reduced cycle time and improved throughput on the company’s precision stamping dies.

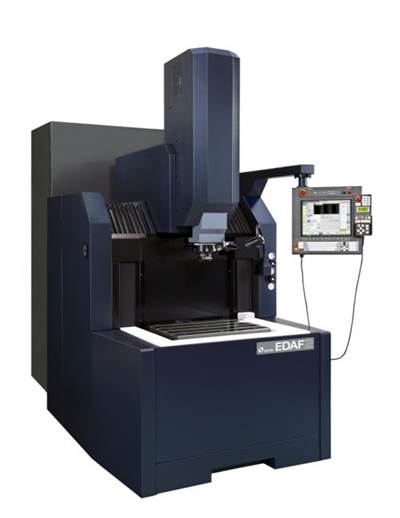

Read MoreRam EDMs Designed for Long, Unattended Operation

The EDAF series of ram EDMs features a new mechanical design for increased rigidity and reduced thermal distortion.

Read MoreVideo: Minimizing Mistakes with Laser Scanning CMM

Die Tech & Engineering uses its scanning to CMM to avoid errors by inspecting electrodes prior to EDM.

WatchWhat's the Best Process for Machining a Precise Hole in Aluminum?

This small hole is actually large enough that any of three different processes might be used.

Read MoreStainless Steel Collets

Beaumont Machine offers an ER16 spring collet made from 300 series stainless steel.

Read MoreThe Automation Inspiration

Although automated manufacturing cells typically consist of standard products such as CNC machine tools, robots, pallets and cell control software, almost all of these systems rely on inventive concepts developed for the particular application. These "good ideas" often account for the outstanding productivity and flexibility of these systems. This article looks at several of the "good ideas" that characterize a cell comprised of seven wire EDM units and a robot on a rail transfer unit.

Watch