Data-Driven Manufacturing

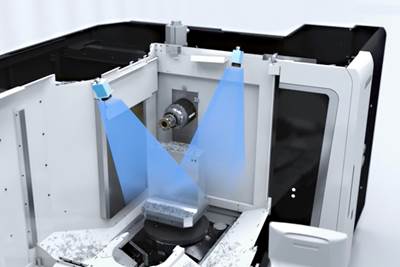

AI Chip Flushing Keeps the Lights Out

Swiveling, camera-guided coolant nozzles solve a CNC machining automation problem that is ideal for artificial intelligence (AI).

Read MoreFocus on Throughput Empowers People and Machines

Lessons learned in robot-tending coordinate measuring machines (CMMs) translate well to a self-correcting multi-tasking machining process.

Read MoreHow to Scale a Job Shop for Growth with Fewer People

Front office disorganization and poor shop floor communications don’t just reduce a job shop’s efficiency; they are a barrier to growth. Having the right kind of ERP system can be the key to improving profitability and scaling for future growth

WatchDigital Tools Meet Practical Applications

Digital manufacturing will see a much larger footprint at IMTS 2022 thanks to technologies that bridge the gap between the digital and physical.

WatchModbus TCP Support comes to Scytec's DataXchange Platform

Scytec Consulting has added Modbus TCP compatibility to its DataXchange machine monitoring platform. This will enhance its usability with cobots and PLCs.

Read MoreFuuz Launches No-Code UI and Cybersecurity Customizations

MFGx has added new user interface customization and cybersecurity options simple enough for no-code users and powerful enough to support pro-code users.

Read MoreGOM Suite 2021 Features Faster Scans, Specialized Workflows

Capture 3D has released GOM Suite 2021, a consolidated ecosystem of GOM GmbH’s 3D metrology models that includes efficiency and capability upgrades.

Read MoreReach More B2B Buyers with Thomasnet's Industrial Marketing Services

Tap into 1.4 million engineers, purchasing managers, and procurement professionals sourcing on our platform each month across hundreds of industries with our digital advertising and marketing services, customized for suppliers like you. (Sponsored)

WatchMachine Monitoring Has a Lot to Learn

Supplementing CNC connections with sensors and machine learning enables predicting performance on the level of the individual part.

Read MoreHypertherm Introduces New Machine Data Module

Production Manager is designed to seamlessly integrate with Hypertherm’s Edge Connect CNC to automatically capture machine data without the need for operator intervention.

Read More