Hypertherm Introduces New Machine Data Module

Production Manager is designed to seamlessly integrate with Hypertherm’s Edge Connect CNC to automatically capture machine data without the need for operator intervention.

Share

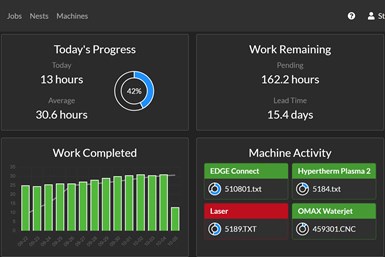

Hypertherm, a manufacturer of industrial cutting systems and software, announces the release of Production Manager, an optional module for its ProNest advanced CAD/CAM nesting software. This web-based module is designed to improve productivity, maximize machine up-time, boost on-time delivery and increase material utilization.

Production Manager is said to seamlessly integrate with Hypertherm’s Edge Connect CNC to automatically capture machine data without the need for operator intervention. In addition, it displays real-time production data so team members across an organization can track the status of job orders, the production schedule and pending inventory requirements.

Production Manager features a dashboard view that provides production stats and trends in one view. Color-coded status alerts are designed to help users quickly understand the on-screen information while an interactive display allows users to drill down for additional insight. Production Manager can be accessed remotely via a computer, mobile phone or tablet using a secured network or VPN connection.

Users can cancel or hold orders to add or remove parts based on last-minute change; they can also view machine backlogs and ensure loads are evenly distributed across cutting machines in a way that optimizes the production schedule.

Tom Stillwell, product marketing manager for Hypertherm software products, says reaching “new levels of automation and efficiency is increasingly important as companies move toward a more digital shop floor. Production Manager further extends ProNest’s reach across organizations by interfacing with all aspects of the cutting operation including sales, customer service, procurement and management.”

Related Content

-

Can AI Replace Programmers? Writers Face a Similar Question

The answer is the same in both cases. Artificial intelligence performs sophisticated tasks, but falls short of delivering on the fullness of what the work entails.

-

5 Tips for Running a Profitable Aerospace Shop

Aerospace machining is a demanding and competitive sector of manufacturing, but this shop demonstrates five ways to find aerospace success.

-

Cutting Part Programming Times Through AI

CAM Assist cuts repetition from part programming — early users say it cuts tribal knowledge and could be a useful tool for training new programmers.