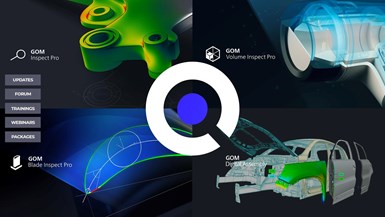

GOM Suite 2021 Features Faster Scans, Specialized Workflows

Capture 3D has released GOM Suite 2021, a consolidated ecosystem of GOM GmbH’s 3D metrology models that includes efficiency and capability upgrades.

Share

Hwacheon Machinery America, Inc.

Featured Content

View More

Image courtesy of GOM GmbH.

Capture 3D, U.S. partner of Zeiss Group company GOM GmbH, has launched GOM Suite 2021. This suite consolidates GOM’s software applications into one source while also providing access to services like GOM’s 3D digitizing and inspection training courses and its user community forum. Updates included with the 2021 Suite expand users’ selection of specialized 3D measurement workflows and improve the speed of their inspections.

Included applications optimize the processing and interpretation of data points collected during photogrammetry, 3D scanning, inspection and CT scans. These applications process scans from GOM’s line of scanners to create a complete digital twin and include functions to conduct shape and dimensional analysis, 3D inspection and mesh processing for 3D point clouds and CAD data sets in product development, quality control and production.

New features in GOM Suite 2021 include an interactive guide for many scanning workflows that assists with problems and bundles relevant features in one place, GPU acceleration that uses graphics cards to increase the speed of 3D data visualization, automatic adjustment of camera elements such as spot metering and exposure for real-time user feedback, simultaneous scanning of multiple discrete parts and filters to customize CAD importation. Also, ISO stylized labels are now controllable and interactive, and the new GOM Blade Inspect workspace contains a collection of specialized software tools for efficient analysis of 3D mesh data for airfoil and turbine blade applications.

Related Content

-

Easy-To-Install Data Acquisition System for Real-Time Monitoring Across Brands

cnSEE from All World Machinery Supply combines easy installation and monitoring across multiple machines.

-

Can Connecting ERP to Machine Tool Monitoring Address the Workforce Challenge?

It can if RFID tags are added. Here is how this startup sees a local Internet of Things aiding CNC machine shops.

-

5 Stages of a Closed-Loop CNC Machining Cell

Controlling variability in a closed-loop manufacturing process requires inspection data collected before, during and immediately after machining — and a means to act on that data in real time. Here’s one system that accomplishes this.