Basics

How to Succeed in a Machining Career

A successful machinist with a medical device company offers advice to young people about how to pursue the same rewarding career he enjoys.

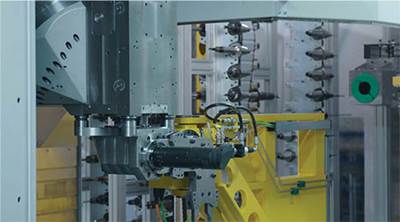

Read MoreTechnology for Turning on a Five-Axis Machine

A turning tool adapter that mounts to the MCT five-axis machine isolates the main spindle bearing from the shock of turning operations.

Read MoreWalter Surface Technologies Publishes White Paper

The paper reports on four companies to demonstrate how much money can be saved by switching out a grinding abrasive.

Read MoreDocumenting within CNC

Including messages directly in the program can help operators run it accurately.

Read MoreEDM’s Key Technologies Today

A representative of machine maker Chmer lists some of the features and capabilities that hold the most promise for EDM users now.

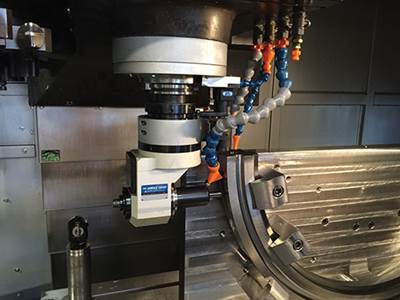

Read MoreWhat To Consider When Adding Angle Heads

Angle heads can enable a three-axis machine tool to be more versatile. That said, this shop explains that there’s more to getting started using them than simply loading them into a machine’s spindle.

Read MoreGetting to Know Glebar

This grinding machine manufacturer recently consolidated its three U.S. operations into a new facility in New Jersey and added a range of new production machining equipment.

Read MoreA Practical Approach to Milling Titanium

When the right cutting tool, toolholder, cutter paths and machining parameters are applied intelligently, a shop may have more capability to mill titanium effectively than it recognizes.

Read MoreWhen One? When Two?

East Branch Engineering often uses live-tool turning centers to complete complex parts in one setup. However, it also leverages a flexible and reconfigurable “mini-cell” strategy to enable a single operator to tend two machines at once, essentially gaining “free” machining time by overlapping operations.

Read More7 Things to Know about the IIoT and Industry 4.0

An introduction to the standards, decision-making, training, cybersecurity, sensors, machine monitoring and cloud computing that make up the IIoT.

Read More.jpg;maxWidth=970;quality=90)

.jpg;maxWidth=300;quality=90)