A Practical Approach to Milling Titanium

When the right cutting tool, toolholder, cutter paths and machining parameters are applied intelligently, a shop may have more capability to mill titanium effectively than it recognizes.

Machine tools designed for milling titanium are generally characterized as having heavy, rigid structures with spindles designed for high torque at low spindle speed. Large spindle tapers and high-pressure coolant are also typical. For multi-axis work, a beefy trunnion and rotary table may be provided as well.

However, a shop with a 40-taper vertical machining center in sound condition should not rule out this manufacturing resource for effectively and profitably milling titanium. Mike MacArthur, VP of engineering and a titanium expert at cutting tool manufacturer RobbJack, has been promoting this point for a while now. Importantly, he does not take a purely cutting-tool-centric view of this proposition, although cutting tool considerations naturally become a focal point, simply because a systematic approach to milling titanium revolves around managing the conditions that enable an end mill to remove this tough material efficiently.

“Regardless of the type of machine tool a shop has for milling titanium, the principles of milling titanium are the same. What have changed in recent years are the options available for controlling variables that these principles are based on,” Mr. MacArthur says. These options create choices that are appropriate for milling this metal on many existing machining centers, he goes on to say.

For example, toolpath algorithms that ensure constant engagement of the cutter in the workpiece material are especially effective—and necessary—in titanium. Super-accurate toolholders with highly concentric, rigid gripping force address another requirement for titanium machining. A high-pressure coolant delivery system on a machine is advantageous. Of course, the range of end mills designed for various machining operations in titanium are now well developed and available from many cutting tool manufacturers.

“In fact, there are so many choices, it can be a bit confusing or intimidating for planners and programmers,” Mr. MacArthur admits. “The simple guidelines presented here can keep the cutting tool selection process very manageable, though.”

Taking the Heat

The background to any discussion of titanium milling has to cover the issue of heat. “It is a primary consideration in crafting a strategy for milling titanium on any machine, but especially so for general-purpose machining centers,” Mr.

MacArthur says. Excessive heat can quickly damage the cutting edges of an end mill and thus undermine the “support structure” built into the rest of cutting strategy. Titanium needs a strong, sharp cutting edge, because a clean, shearing action enables this material to form chips that leave a superior workpiece surface, absorb heat and flow up the flutes smoothly.

“Cutting tool manufacturers have the right designs to do this, but it is up to the shop to put in place the means that protect this cutting edge,” Mr. MacArthur says.

Really Cool Tool Paths

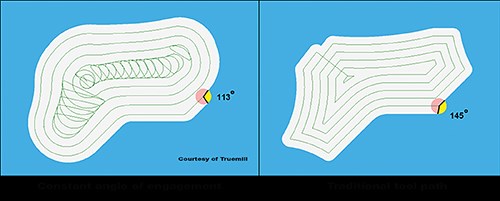

Perhaps the most important way to protect the cutter when machining titanium is to provide tool paths that avoid conditions that overheat the tool and degrade the cutting edges. For milling pockets and wide slots, this can be accomplished by using toolpath algorithms that maintain a constant angle of engagement between the cutter and the workpiece. Today, most of the CAM software developers offer such algorithms, under a variety of names. All of them create a tool path that restricts how much of the tool radius can be in contact with the workpiece at any time. In a slot, such a tool path will usually follow a regular trochoidal pattern. The tool moves in a series of uniform curves from side to side as it forms the slot. The uniform arcing of these moves is rather easy to see, Mr. MacArthur asserts.

When applied to an irregularly shaped pocket, the toolpath algorithms create a pattern that may be much harder to discern because it does not seem to reflect the shape of the pocket’s sidewalls at first. In fact, that tool path is designed to avoid burying the cutter in corners or during sudden changes in direction by removing material with a progressive series of circular and arcing moves. Although the offerings from different CAM developers may vary in terms of significant nuances or speed of processing, they all provide a similar benefit when machining titanium—the ability to use a smaller-diameter cutter at smaller stepovers and at higher tool rotations per minute.

This approach achieves an adequate metal- removal rate with lighter cuts. The lighter cuts, in turn, keep the individual flutes of the cutter in contact with the workpiece for a shorter period of time, so less heat can be absorbed. “And that’s how this strategy wards off the excessive heat buildup that damages cutting edges,” Mr. MacArthur concludes.

To put some representative numbers to this concept, he describes the following sample test part. A block of 6Al4V titanium (6 by 4 by 1.5 inches) was machined (roughing and finishing) with a ½-inch-diameter cutter with six flutes. The feed rate was 75 ipm and 400 sfpm. Radial depth of cut was 0.05 inch—10 percent of cutter diameter. Axial depth was 1 inch (two times cutter diameter). In this example, approximately 22 cubic inches of material was removed in slightly less than 15 minutes. To give perspective to the metal removal potential indicated here, Mr. MacArthur adds that, in a strictly roughing operation using this approach, a 1/2-inch-diameter cutter is capable of removing more than 65 cubic inches of 6Al4V titanium in 15 minutes.

What is significant here is that the rigidity and torque requirements for machining with these parameters do not demand the capability of a large “titanium machine,” but are achievable with many vertical machines produced within the last five or six years. “The latest generation of 40-taper machining centers are more rigid and capable then preceding models, because builders are applying finite element analysis and other advanced design tools,” Mr. MacArthur explains. Thus, a well-maintained, newer machine is a candidate for titanium machining.

The Flute Section

Of course, strong, sharp edges are not the only design characteristic that cutting tool manufacturers give to end mills for titanium. Common design principles include uneven flute spacing to break up harmonics that can induce chatter; helix angles that vary from flute to flute for chip flow; and a coating that is smooth, slick and slow-wearing to reduce frictional heat. Eccentric relief along the cutting edges is also typical, because it supports and strengthens the cutting edges, which are ground and polished for sharpness.

“This is not to say that all titanium end mills are created equal,” Mr. MacArthur cautions. RobbJack, for example, applies its own proprietary concepts and innovations to end mill design. The differences may be subtle as well as significant, so shops should look closely at a supplier’s offerings, he advises.

Regardless of the supplier, end mills suitable for machining titanium may have four (or fewer) flutes and as many as 10 (or more). “Many shops get stuck when deciding the best number of flutes for titanium work on a general-purpose machining center,” Mr. MacArthur says. “Advice from a supplier on this choice can seem a bit mysterious, especially if the shop is new to titanium machining.”

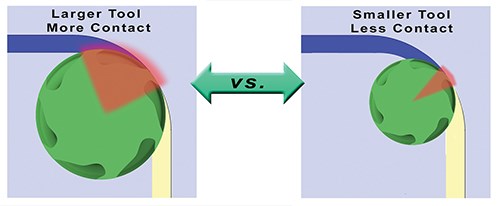

Choosing the number of flutes is best understood as it relates to the strategy of managing how much contact each flute has on the surface of the workpiece. In situations where the flutes are more likely to be in contact with the surface, a smaller number of flutes is preferred. In situations where the flutes are less likely to be in contact, a larger number is preferred.

Because end mills with a diameter of ½ inch or smaller are the best fit for the power and rigidity profiles of a 40-taper machine, four-flute end mills are a good choice for heavier cuts and for pockets with many tight corners. Settings that generate 125 to 200 sfpm at a 15-ipm feed rate are average for a four-flute end mill. Stepovers in X and Y that are as much as 25 percent of the tool diameter are acceptable here.

Where permissible, however, using a six- or eight-flute end mill of a comparable diameter is a good choice for open, rectangular pockets, because applicable speeds and feeds typically reach 400 sfpm. This makes this tool very productive. The corresponding feed rates of 45 to 75 ipm are indicative of this potential. Six-and eight-flute end mills perform especially well when constant-engagement tool paths can be applied. Stepovers in X and Y will range from 2 to 10 percent of diameter in this case. High-speed finishing cuts that leave a smooth surface are also an ideal operation for this type of tool.

Toolholders That Hold

Super-accurate, high-quality toolholders are a must for milling titanium. The quality of the toolholder influences a machining operation in several ways. Secure clamping in the machine tool spindle enhances rigidity of the entire cutting tool assembly. The accuracy of the toolholder minimizes runout and contributes to consistent conditions when the tool is in the cut. Well-balanced toolholders reduce stress on the machine spindle and on the cutting tool, while also reducing causes of vibration. Super-accurate toolholders provide higher gripping force on the cutting tool, too. Because milling titanium creates higher cutting forces than milling softer, freer cutting materials, the gripping power of the toolholder is critical.

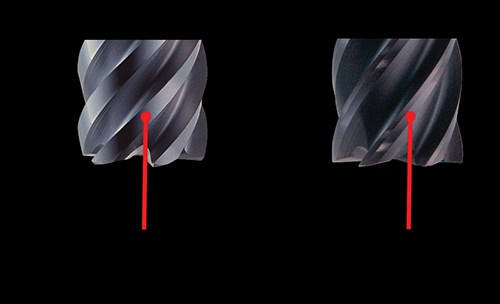

“There’s a wrinkle in this scenario that is often overlooked or misunderstood,” Mr. MacArthur warns. “It’s the roundness of the tool shank.” A tool shank manufactured to a very high level of roundness complements and enhances the benefits of super-accurate, high-quality toolholders. This roundness directly affects its degree of contact with the clamping surface of the toolholder. The roundness of the tool shank and the quality of the toolholder go hand-in-hand, but most discussions of toolholder requirements neglect the importance of using tools with exceptional roundness. (According to Mr. MacArthur, the tool shank on a RobbJack end mill for titanium is produced to a roundness of 0.000025 of an inch.)

Roundness of the tool shank is especially important with small-diameter cutting tools, because the area of contact between the cutting tool and holder is proportionately smaller. Any loss of contact reduces gripping force significantly.

The Pressure’s On

Metalworking coolant has three functions: It provides cooling, lubricity and chip control. All three functions are valuable when milling titanium. Most of today’s machining centers have coolant delivery options that benefit titanium milling. Having a high-pressure, through-the-spindle capability is best, because it is the most effective for promoting chip evacuation. Additional coolant ports and “showerheads” are also recommended.

Mr. MacArthur notes that three coolant considerations are critical to machining titanium: high pressure, adequate volume and consistent flow on the cutting zone.

End mills for titanium usually have thick cores to resist deflection, so the channels between the flutes are not especially commodious. However, they are adequate when light cuts produce thin chips that can be flushed up and out. This is true even for six- and eight-flute styles in which space for chip flow is especially tight. In short, copious amounts of coolant at high pressure (as high as 1,000 psi) greatly reduce opportunities for chips to become trapped between flutes.

A Thoughtful Approach

This article suggests that a practical approach to milling titanium enables shops to consider the capability of existing machining resources such as a newer VMC. The approach is practical because suitable choices in cutting tools, toolholders, CAM software and so on are readily available.

However, this approach could also have been called a thoughtful one, because it calls for users to learn about titanium, understand its characteristics and apply basic principles knowledgeably. And any serious effort to master the machining of titanium must follow this call earnestly.

Read Next

Inside Machineosaurus: Unique Job Shop with Dinosaur-Named CNC Machines, Four-Day Workweek & High-Precision Machining

Take a tour of Machineosaurus, a Massachusetts machine shop where every CNC machine is named after a dinosaur!

Read MoreIncreasing Productivity with Digitalization and AI

Job shops are implementing automation and digitalization into workflows to eliminate set up time and increase repeatability in production.

Read MoreThe Future of High Feed Milling in Modern Manufacturing

Achieve higher metal removal rates and enhanced predictability with ISCAR’s advanced high-feed milling tools — optimized for today’s competitive global market.

Read More

.jpg;maxWidth=300;quality=90)