Basics

When Grinding Is Like Turning

This shop leverages a high-speed peel-grinding process that resembles turning to effectively grind challenging materials such as carbide. Inherently low grinding forces mean high material-removal rates are possible.

Read MoreWhy Forming a Machine-Tool Buying Committee Is a Good Idea

With a decision as heavy as buying a new machine tool, it’s important to consider how such a purchase will touch all the relevant departments of the shop.

Read MoreAutomating Surface Metrology for the Shop Floor

Machine operators are likely to get improved results when the surface finish gage is smart enough to choose the best measuring parameters.

Read MoreHow to Succeed in Metalworking? The Answer’s in the Data

In a recent survey, more than 300 businesses using metalworking technology shed light on their outlook for future business conditions, greatest challenges and which strategies are working best for addressing those challenges.

WatchFive Design for Manufacturability Tips for Designers

Leading machine shops offer design for manufacturability (DFM) advice to customers to reduce machining cost and lead time. Here are five examples.

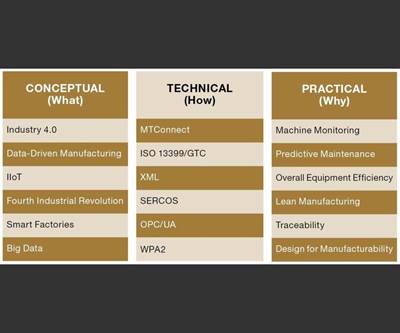

Read MoreData-Driven Manufacturing Deconstructed

"Data-Driven Manufacturing" can be broken into three areas for better understanding: the conceptual, the technical and the practical.

Read MoreFive Tips for Effective Machine Monitoring

A machine shop’s successful entry into machine monitoring reveals important points about what to do and what to expect.

Read MoreWhy Was This Machine Chosen for Composites?

General Tool adds a metalcutting machining center with the expectation that this machine is likely to perform a significant amount of machining of CFRP.

Read MoreWebinar: Practical Tips for Unattended Machining

A free webinar presented by Autodesk October 19 will address tips and techniques to help shops begin machining unattended.

Read MoreWhat are the Steps of Caliper Calibration?

A gage that meets performance specs will ensure better measurement results.

Read More