Basics

How to Promote Careers in Precision Manufacturing

Step one: create a great manufacturing training program with good instructors and a well-equipped machining facility. Step two: create a compelling video that sells the program to high school seniors about to choose a career path. The ITAMCO Manufacturing Education Center at Plymouth High School in Plymouth, Indiana has both steps covered.

WatchWhen to Waterjet, When to Mill

A composite parts manufacturer in Nebraska recently installed a combined five-axis waterjet/milling machine to position itself to win large-scale aerospace work it sees on the horizon.

Read MoreWhy Rural Shops Should Consider the USDA

Did you know that opportunities exist through the United States Department of Agriculture for machine shops hoping to become more energy efficient?

Read MoreGood Video on Machining Basics

Training somebody with no shop experience? Have them check out this video.

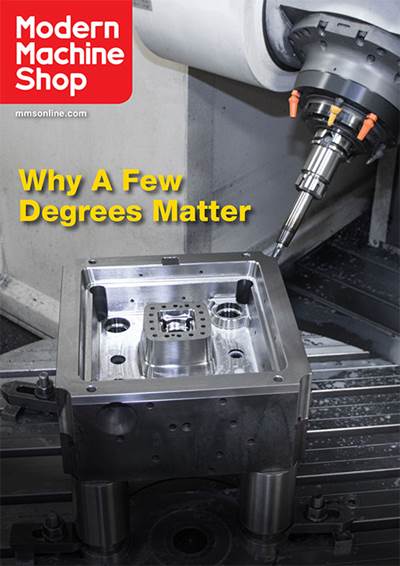

Read MoreWhy a Few Degrees Matter

3 + 2 machining might not be as captivating as five-axis contouring operations, but it can be just as valuable.

Read MoreWhy a Dual-Column Machining Center?

According to this machine tool supplier, a dual-column or bridge-type machining center is 10 times more thermally stable than a comparable “C” style machine.

Read MoreStudents Cast for a Better Understanding of Part Processing

How manufacturing processes are interrelated is an important lesson for students pursuing their preparation for careers in manufacturing engineering. One school teaches this vital connection by linking the quality of CNC programming with parts cast in machined dies.

Read MoreA Solution for Faster Vise Jaw Change-Overs

This an angle lock vise design is said to enable users to change jaws in 30 seconds.

Read MoreWhy Not Start With Waterjet?

In titanium, significant savings and process efficiency can result from the simple fact that abrasive waterjet cutting leaves the remaining stock intact.

Read MoreHow One CNC Shop Effectively Machines Glass-Fiber-Filled Plastics

You know how to machine metals, but what about plastic machining? More specifically, glass-fiber-reinforced plastic? This machine shop has it figured out.

Read More