How to Mitigate Risk in Your Manufacturing Process or Design

Use a Failure Mode and Effect Analysis (FMEA) form as a proactive way to evaluate a manufacturing process or design.

Share

Risk mitigation is something that all companies must address to protect themselves from the unexpected. Often, these unexpected outcomes can have severe consequences, both within the company and in the market where products and services are used. Even new quality management standards, such as ISO 9001, have included risk mitigation requirements for products and processes. Although there are many techniques to assist companies with risk mitigation, one of the most commonly used is Failure Mode and Effect Analysis (FMEA). It is effective and can be adopted by manufacturing companies of all sizes relatively easily.

The first part of this Failure Mode and Effect Analysis (FMEA) form ranks the risk severity, occurrence and detection. Multiplying these numbers together gives machine shops their risk priority.

FMEA is a proactive system for evaluating a process or design in terms of where and how it might fail in use. FMEA seeks to assess the impact of different types of failures to identify which design components or process steps are most in need of change. Evaluating a design or process’s failure potential helps identify causes and prioritize them to mitigate the most severe ones. This upfront investment of time and effort will yield downstream benefits in safety, risk (liability), quality, productivity, cost and customer satisfaction.

The typical FMEA process proceeds as follows:

- Review a design or process. This requires obtaining and reviewing all applicable documents, including component and assembly drawings, quality specifications, work instructions, routings and prototype/sample parts, if available.

- Review a safety checklist. Most companies develop their own safety checklist by following OSHA guidelines. The checklist should include potential hazards and elements of the design or process that may cause them. It should serve as a log of hazards that have been addressed and ones that are still open. Any open hazards should also be included on the FMEA form.

- Brainstorm potential failures of the design or process. This is where design or process expertise is required. Each component, assembly or process function needs to be analyzed, and potential failure modes, effects, causes, and methods of detection and prevention (if currently available) need to be discussed.

- Complete a FMEA form and calculate risk priority (RP). All failure-related information should be recorded on an FMEA form. Each failure effect is assigned a severity ranking, usually between one and 10, with 10 being the most severe. The cause is also ranked in terms of occurrence likelihood. Again, a ranking of 10 would indicate the highest failure potential. Finally, the potential of detecting the failure is ranked with 10 indicating that no means of detection currently exist. If there are preventive steps in place, these can factor into the detection ranking. The RP number is then calculated by multiplying the severity, occurrence and detection rankings together. This RP value can range from 1 to 1,000. Ultimately, the higher the number, the higher the risk associated with the design or process.

- Identify and implement corrective action. Based on the initial RP number, corrective action should be developed, planned and implemented. The highest overall RP-rated failure modes typically will be addressed first, as they present the highest risk to the design or process.

- Recalculate RP. Once corrective action is implemented, the RP should be recalculated to reflect the new level of risk. This should be done whenever a corrective action is implemented, so the recalculation may need to be completed a number of times throughout the FMEA process.

After discovering a manufacturing risk priority of a manufacturing process or design, shops should identify and implement corrective actions and record results.

The illustration above is an example of an FMEA form showing the major categories for consideration and the failure information for a specific process:

You will see that the failure being analyzed for a CNC mill is an oversize hole. The effects of the oversize hole, the potential causes and the controls for detection are also shown. Each of these categories has a ranking associated with it. The preliminary Risk Priority is 24. Recommended action, responsibility and a target completion date are also shown. Finally, the action results show that although the severity and detection rankings are unchanged, the frequency of occurrence is reduced, leading to a much lower RP number.

As exposure to risk is something we all want to reduce, using a FMEA process will help to identify and mitigate risk. As such, it is a very useful tool to employ in your organization’s continuous improvement effort.

Related Content

Rethink Quality Control to Increase Productivity, Decrease Scrap

Verifying parts is essential to documenting quality, and there are a few best practices that can make the quality control process more efficient.

Read More4 Rules for Running a Successful Machine Shop

Take time to optimize your shop’s structure to effectively meet demand while causing the least amount of stress in the shop.

Read More6 Machine Shop Essentials to Stay Competitive

If you want to streamline production and be competitive in the industry, you will need far more than a standard three-axis CNC mill or two-axis CNC lathe and a few measuring tools.

Read More4 Steps to a Cobot Culture: How Thyssenkrupp Bilstein Has Answered Staffing Shortages With Economical Automation

Safe, economical automation using collaborative robots can transform a manufacturing facility and overcome staffing shortfalls, but it takes additional investment and a systemized approach to automation in order to realize this change.

Read MoreRead Next

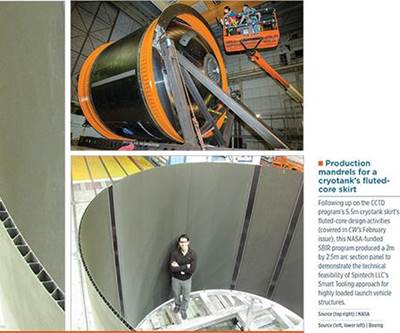

“Smart tooling” cuts time and risk for complex unitized composite structures production

One-piece bladder tooling helps to actualize NASA/Boeing’s revolutionary fluted core design for next-gen cryogenic fuel tank skirt.

Read More‘Intelligent’ Cooling Helps Molder Improve Productivity, Profitability & Quality

Cost-effective and user-friendly process-cooling system gives custom molder the ability to do more with less.

Read MoreRegistration Now Open for the Precision Machining Technology Show (PMTS) 2025

The precision machining industry’s premier event returns to Cleveland, OH, April 1-3.

Read More