Basics

Changing Program Behavior

User-defined codes allow you to make minor method changes to machine workpieces without reprogramming.

Read MoreA Pragmatic Approach to Form Measurement

When time is of the essence, exploring for diameter variation instead of exact dimensions offers a good, practical means of measurement on the shop floor.

Read MoreWhy Machine a Part on a Lathe: February 2017 Digital Edition

The latest issue of Modern Machine Shop covers topics such as milling on a turning center, risk management and machine monitoring with DNC.

Read MoreWhy the Surge in HMCs?

Spending on horizontal machining centers is forecast to reach its highest level in more than a decade. Small shops in particular are buying these machines. A shop I recently visited illustrates the reason.

Read MoreWhy Machine This Boxy Part on a Lathe?

South Morgan Technologies has long thrived on its ability to mill boxy parts on a turning platform. Today, newer technology and techniques enable saying “yes” to more work than ever before.

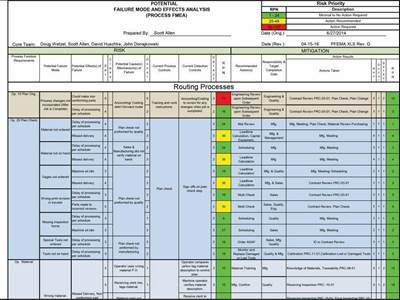

Read MoreMedical Shop Demonstrates How To Manage Risk for ISO

The new ISO 9001:2015 standard emphasizes risk assessment. Medical shops like Protomatic with ISO 13485 certification already manage this.

Read MoreCNC Machining: Programming the Appropriate Rates for Your Tool

A bit of math is involved in programming the appropriate rates for a particular tool.

Read MoreWhat to Know About Automatic Gages

The potential for increased productivity and cost savings could justify a purchase.

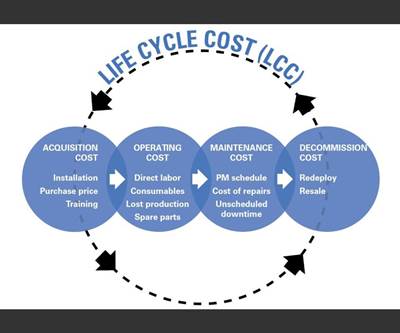

Read MoreWhat a Machining Center Really Costs: Total Lifecycle ROI

A white paper explains why it’s important to look at the entire lifecycle of a machine to determine its true costs and benefits.

Read MoreLooseness — An Enemy of Precision

When a gage isn’t coming up with accurate measurements, the culprit could be a connection that simply isn’t tight enough.

Read More