4 Workday Distractions and How to Beat Them

Not all business is productive work.

Share

Hwacheon Machinery America, Inc.

Featured Content

View More.png;maxWidth=45)

DMG MORI - Cincinnati

Featured Content

View More

Takumi USA

Featured Content

View MoreIt’s been said that mosquitoes consume more human blood every year than lions. The first time one hears that fact, two things tend to happen: One, it’s natural to pause and begin to question the thought in its entirety. “How could that be true? Surely the mighty king of the jungle draws more human blood than a tiny insect.” Yet, after further contemplation, you realize that there are millions of mosquitoes hassling millions of humans on a regular basis. The second thing that happens is you realize this statement can be a metaphor for what is consuming our daily lives. All these distractions keep us from doing meaningful work. We are eaten up by the little things we deal with on a daily basis.

These swarms of time destroyers can show up in a variety of ways:

- Email. The constant barrage of email that we respond to incessantly throughout the day. We get caught up in email like a game of ping-pong. We constantly swat emails back and forth without realizing the amount of time consumed to achieve little of substance.

- Problems. Specifically, when other people try to turn their problems into our problems. These are usually brought to us by fellow employees, customers and suppliers.

- Notifications. The attention we give to text messages, tweets, news alerts, Facebook, LinkedIn and other forms of social media. Our ability to focus and work for a sustained period of time has been destroyed by the phone in our pocket or hands.

- Urgency. We begin to constantly allow urgent matters to take precedence over important matters.

The biggest danger/threat that comes from the list above is that we start to think all that busyness is actually productive work, and with all that activity we are actually accomplishing something meaningful. There is, however, more important work to be done.

What do you do? Let’s address the time-consuming items above:

- Email. Start by freeing yourself from the expectation that every email needs to be responded to immediately. Close your email when working at your desk and turn off its notification. Then batch and respond to them at certain times of your day.

- Problems. Keep your guard up when others are looking for you to deal with their issues. Instead of giving them answers, show them where they can find the answers. Encourage others to have self-reliance and to do their own problem solving whenever possible, prior to coming to you for assistance. Don’t allow a lack of planning to become your problem. Guard your time, say no once in a while.

- Notifications. Make a conscious effort to do a digital disconnect. It’s not easy, but free yourself from the constant attention you give your phone. Turn off notifications or silence it. Perhaps you could leave it in your backpack, briefcase or another room for periods of time throughout the day.

- Urgency. Understand that important matters are the meaningful work that you perform, which will have the biggest impact for you and your company. Urgent matters need to be dealt with as well, but most times these matters should be verified as truly urgent and delegated to others in your organization.

Once you allow yourself to become more proactive and less reactive in the approach to your workday, you can then begin to think about what matters most. That can vary depending on your role. As an owner, my thoughts usually take the shape of questions. Are customers happy with us and are we happy with them? Should we be selling to new markets? How is the shop floor functioning? How is morale at work? How do we attract new talent? Do we have an adequate training program to develop new talent? (Do we even have a training program?) What types of equipment would position us best in the market now and for the future? From these thoughts come ideas that turn into plans and strategies to be implemented.

What I ultimately work on takes focus and effort. It can be challenging, but I wouldn’t have it any other way. Since I’m no longer dealing with the mosquitoes, I now have time to deal with the lions.

Related Content

How to Mitigate Risk in Your Manufacturing Process or Design

Use a Failure Mode and Effect Analysis (FMEA) form as a proactive way to evaluate a manufacturing process or design.

Read MoreTips for Designing CNC Programs That Help Operators

The way a G-code program is formatted directly affects the productivity of the CNC people who use them. Design CNC programs that make CNC setup people and operators’ jobs easier.

Read More6 Machine Shop Essentials to Stay Competitive

If you want to streamline production and be competitive in the industry, you will need far more than a standard three-axis CNC mill or two-axis CNC lathe and a few measuring tools.

Read MoreHow to Calibrate Gages and Certify Calibration Programs

Tips for establishing and maintaining a regular gage calibration program.

Read MoreRead Next

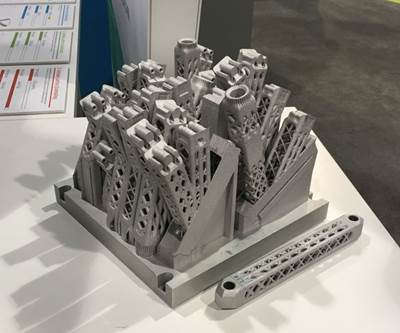

Additively Manufacturing a Large Component with a Small Work Envelope

Airbus successfully reduced the weight of an aircraft partition by redesigning it for additive manufacturing. The large component was produced in pieces, with connection features built-in.

Read More"Arpro" EPP Manufacturer Exceeds Sustainability Goals; Launches EPE Sheet Foam Business

JSP, manufacturer of Arpro EPP, is ahead of the game in meeting its five-year target to reduce its carbon footprint, and has also now launched a new expandable PE sheet foam business in North America.

Read More

.jpg;maxWidth=300;quality=90)

.jpg;maxWidth=300;quality=90)