Plotting a Pathway to Profitable Additive Manufacturing

The cost per pound for a metal AM part may be shocking, but that knowledge is essential to plan a journey to success with Additive Manufacturing.

Share

.png;maxWidth=45)

DMG MORI - Cincinnati

Featured Content

View More

Autodesk, Inc.

Featured Content

View More

Hwacheon Machinery America, Inc.

Featured Content

View More

Applying the AM part selection criteria that I provided previously is the first step to identifying whether a part is a potential candidate for Additive Manufacturing (AM). Ensuring that the material is available, the part fits within the AM build envelope and the complex features seem to justify the use of AM (versus numerous setups or changeovers on a mill, say) only means that a part can be printed; it does not mean that it should be printed. That is where sticker shock comes into play, particularly with metal AM processes like powder bed fusion.

Several months ago, I shared a simple cost model for laser powder bed fusion that relied only on the weight and height of the part, the cost of the powder and the cost to operate the AM system. Armed with that information and a few technical specifications about the AM machine (build rate, layer height, recoating time), an estimate for the total cost of a metal AM part could be found by working backward from the industry average for printing (59.2 percent), pre- (14.4 percent) and post- (26.4 percent) processing costs. No CAD model was required, just the material, the weight of the part and its maximum possible height.

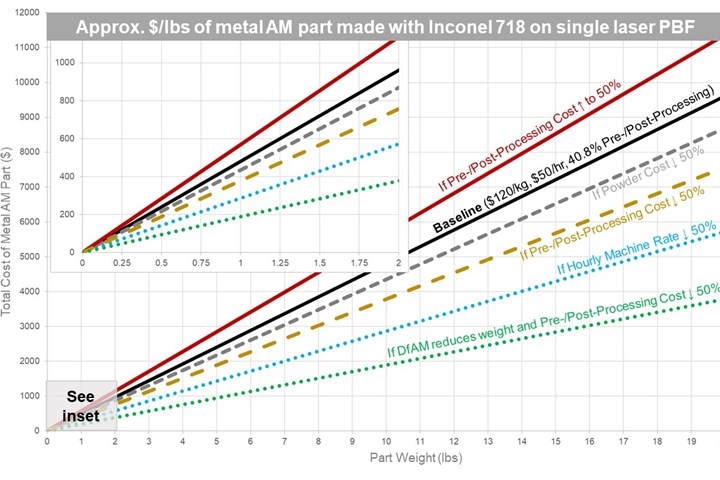

If we ignore the build height for a moment, then estimating the cost of a metal AM part is simply a function of its weight and material, allowing users to develop an estimate of the total cost per kilogram (or price per pound) of any metal AM part. This is where the numbers are a bit shocking.

By estimating the total $/lb of a metal AM part, users gain insight to plot a profitable pathway to AM success.

Let’s take Inconel 718 as an example. It costs roughly $120/kg for powder feedstock, and the material density and volumetric build rate for this material on an EOS M290 is 8.15 g/cm3 and 4.2 mm3/sec, respectively. If we decrement the build rate by 80 percent as advised in my simple cost model and multiple that by the density, then we find that the material build rate is just shy of 100 g/hr (98.58 g/hr to be exact, if I did my math and units right). If the machine operating cost is, say, $50/hr fully burdened, then the printing cost per gram is $0.51/g or $507/kg. Don’t believe me? Do the math.

Sadly, we are not done yet. The material cost and machine cost are only 59.2 percent of the total cost based on the industry averages I cited earlier. That means the total cost of a metal AM part is found by adding material cost ($120/kg) and machine cost ($507/kg) and multiplying by 1.689 (= 1/0.592). Note that if the industry average printing cost was 50 percent of the total cost (vs. 59.2 percent), then the pre-/post-processing cost would be 50 percent, which means the total cost would simply be double the sum of machine cost and material cost — much easier math to do.

Putting this all together, a rough estimate for the total cost per kilogram of a metal AM part made with Inconel 718 is $1060/kg { = ($120/kg of material + $507/kg of machine time)/0.592} or $1.06/g. That’s $480/lbs for those who prefer English units. Ouch! Reality bites, especially since we have ignored several cost drivers, including build height, which drives up machine time even higher.

Fortunately, by knowing this number and where it comes from, it is possible to plan a path to profitability. By varying some of these assumptions, users can plot the cost-per-kilogram as I have done in the figure and identify ways to achieve a given cost target. How much cheaper does the material need to be? How much faster does the machine need to be or is it possible to amortize (or depreciate) the cost of the machine differently to reduce its hourly rate? Better yet, how do I reduce the pre- and/or post-processing costs to minimize the multiplier? My personal favorite: how can I use design for AM (DfAM) to minimize volume, build time, material cost and pre-/post-processing cost all at once? Again, it is plain to see why DfAM is the value multiplier for AM because it is the fastest way to move down these cost curves.

I ran the numbers for Ti-6Al-4V, AlSi10Mg and 17-4PH using metal 3D printing material data from EOS. The results are $1347/kg, $2285/kg and $1287/kg, respectively, for a laser powder bed fusion with a single laser. Some may find this surprising, given that Ti-6Al-4V is the most expensive material ($360/kg) compared to AlSi10Mg ($78/kg) and 17-4PH ($91/kg). The difference lies in the build rate for Ti-6Al-4V, which is among the fastest available, in large part due to thicker layers (60 mm vs. 30 mm and 40 mm, respectively). The low build rate and low material density of aluminum combine to make it one of the most expensive metals to use in AM, even though the powder is the cheapest. This just goes to show that a material that may have been too expensive for conventional manufacturing may be within reach when you use AM.

While the cost model is admittedly simple and there are lots of underlying assumptions, it gives insight into AM. The ability to run a sensitivity analysis or ask “what if” questions with this approach can help a company navigate the pathways available to them and find one that leads to a profitable part — if not now, then in the future, as machines get faster and costs come down.

While finding a pathway to profitable AM is good, don’t lose sight of the fact that AM is only one way to make the part a reality. The real challenge lies in being more cost-effective than the other manufacturing options available. By knowing the cost per kilogram, though, it’s possible to see success with AM — once the sticker shock wears off.

Related Content

4 Tips for Staying Profitable in the Face of Change

After more than 40 years in business, this shop has learned how to adapt to stay profitable.

Read MoreHow to Determine the Currently Active Work Offset Number

Determining the currently active work offset number is practical when the program zero point is changing between workpieces in a production run.

Read MoreHow to Mitigate Risk in Your Manufacturing Process or Design

Use a Failure Mode and Effect Analysis (FMEA) form as a proactive way to evaluate a manufacturing process or design.

Read MoreHow to Calibrate Gages and Certify Calibration Programs

Tips for establishing and maintaining a regular gage calibration program.

Read MoreRead Next

Registration Now Open for the Precision Machining Technology Show (PMTS) 2025

The precision machining industry’s premier event returns to Cleveland, OH, April 1-3.

Read More5 Rules of Thumb for Buying CNC Machine Tools

Use these tips to carefully plan your machine tool purchases and to avoid regretting your decision later.

Read MoreBuilding Out a Foundation for Student Machinists

Autodesk and Haas have teamed up to produce an introductory course for students that covers the basics of CAD, CAM and CNC while providing them with a portfolio part.

Read More

.jpg;maxWidth=300;quality=90)

.jpg;maxWidth=300;quality=90)