datamatters

How Manufacturing Data Can Save the World

Digital spaces rooted in real-world sensor data help scale big ideas and move humanity toward a more sustainable, autonomous future.

Read MoreThe CNC Reveals its Secrets

Machine monitoring becomes a platform for predictive maintenance without requiring extra sensors.

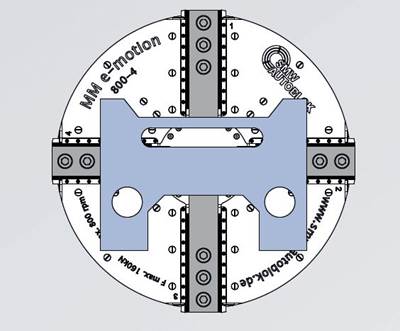

Read MoreWireless Couplers Work Wonders for Workholding

Possibilities range from individual control of chuck jaws and tombstone fixtures to more reliable robots.

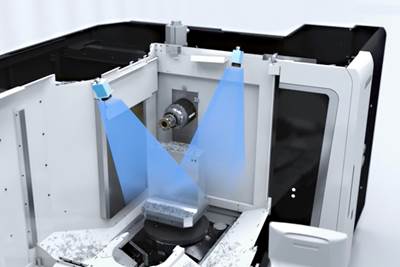

Read MoreAI Chip Flushing Keeps the Lights Out

Swiveling, camera-guided coolant nozzles solve a CNC machining automation problem that is ideal for artificial intelligence (AI).

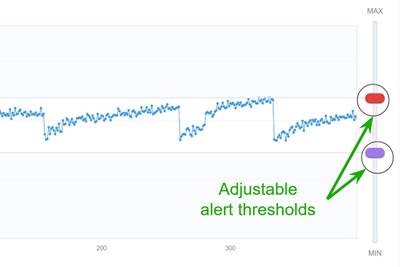

Read MoreMachine Monitoring Has a Lot to Learn

Supplementing CNC connections with sensors and machine learning enables predicting performance on the level of the individual part.

Read More4 Ways “Tag and Track” Technology Keeps Data Chains Intact

Scannable images and tags inextricably link relevant information with workpieces, cutting tools and other physical assets.

Read MoreEdge Computing Device Simplifies Small-Scale Digital Manufacturing

A nonprofit group touts an economical means of unlocking capability ranging from CNC machine tool monitoring to closed-loop process control.

Read More5 Smart Drilling Lessons Apply Beyond the Application

A specific machine learning use case illuminates general principles for applying artificial intelligence at any CNC machining business.

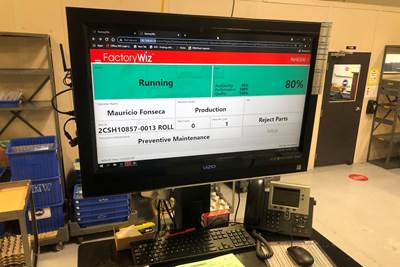

Read MoreTop Shops Are Data-Driven by Definition

CNC machine shops at various stages of digitalizing their operations share a commitment to evidence-backed decision-making.

Read MoreMonitoring Machine Tools? Don’t Discount DNC

Networks that feed part programs to shopfloor CNCs can double as a foundation for pulling data from them.

Read More