Edge Computing Device Simplifies Small-Scale Digital Manufacturing

A nonprofit group touts an economical means of unlocking capability ranging from CNC machine tool monitoring to closed-loop process control.

Share

At the Eastec trade show this past fall, I stopped to take in an interesting display: a milling machine and a 3D printer with a collaborative robot between them, all backed by a large monitor highlighting various dashboards and graphs. All of this equipment was connected via the real star of this demonstration: a little box on the table filled with circuits and wires and sporting a red, green and yellow stack light.

As I spoke with Larry Megan, chief technology officer with Advanced Manufacturing International (AMI), this device had been facilitating a continuous flow of data among the robot, the machine tool, the printer and a set of Bluetooth-enabled calipers – data that was employed to not just monitor the process, but also control it. Just as notably for smaller, resource-strapped manufacturers, the product also lives up to its name: the Low Investment Manufacturing Solution (LIMS).

As demonstrated at Eastec, the LIMS uses standard protocols to interface with all manner of devices, ranging from machining and inspection equipment to robotics and 3D printers.

Keeping the unit economical has been possible largely because AMI is a nonprofit. Partners and contributors are essentially acting through AMI in pursuit of a common goal: to ensure digital transformation percolates deep enough into the supply chain to include more than just the largest OEMs and “smart factories.”

To that end, LIMS (and AMI more broadly) targets small and mid-sized manufacturers specifically. Although these businesses often lack the financial resources and information technology expertise of larger companies, Megan says these businesses can be just as innovative and even more flexible in implementing data-driven manufacturing. The hope for the edge device is that these businesses will start learning “how to fish,” he continues, referencing the proverb about the value of learning a task rather than having it done for you. In this analogy, the LIMS is merely the tackle: the hooks, lines and other tools required for manufacturers to start learning to “fish” in the first place — or, more specifically, to monitor and improve their processes in real time.

This is not to suggest users are on their own. Megan says he Also specializing in manufacturing process and system assessments as well as consulting. However, the LIMS is designed for users to take ownership of the platform and drive the expansion of its capabilities. To that end, it is built to be easy to install and easy to use right out of the box.

Designed for ease of use, LIMS is configured with commonly available components.

Opening the box reveals just a few basic essentials: a 110-V power supply, an industrial computer, and an input/output hub for connections ranging from Ethernet to RS232 cables to PLC hardwiring (the 3D printer in the demonstration connected via USB, and one display on the monitor mapped its XYZ position). Other connections might include temperature, pressure or electrical current sensors anywhere on the shop floor. Scaling the system up might be accomplished by simply adding more boxes and connecting more sensors/machines.

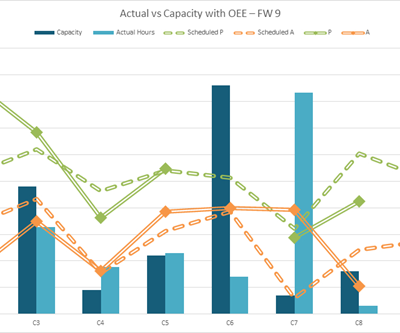

As for the software crunching the data, Solution Engine is based on open standards, which makes it vendor-agnostic. According to Megan, the system “speaks” more than 50 industrial protocols (notable examples include MTConnect and OPC-UA as well as PC-DMIS and QIF). Standard features include dashboard displays of utilization for all connected machinery, ranging from basic uptime/downtime displays to calculations of overall equipment effectiveness. Per Megan’s “fishing” analogy, it also offers a statistics engine for users to configure analytics, as well as a rules engine that provides drag-and-drop functionality customizing the interface. Information can be exported virtually anywhere the user desires, from an Excel spreadsheet to an on-site database to machine learning algorithms in the cloud. Alternatively, the device itself can store the data, depending on the application and volume of information.

With initial barriers to collecting and analyzing data broken down, manufacturers can focus on turning analysis to action. The multi-colored stack light is a basic example, but meeting certain data thresholds might also trigger email, SMS or other alerts. In fact, users with the right application might quickly advance to closed-loop process control without any need for additional investment or IT expertise.

The trade show demonstration offered an example of what this process control might look like. The 3D printer generates a donut-shaped blank, and the Bluetooth caliper takes a diameter measurement before the collaborative robot transfers it into the machine for finish-drilling. In the LIMS, software uses the inspection data to adapt the machine G-code to ensure that the right-size drill is chosen from the toolchanger. “We’re using real-time data,” Megan says. “The LIMS is not only taking in information, but providing an output by transmitting new instructions to the drill press.”

The LIMS aside, Megan says AMI’s broader work is just beginning. The organization was founded only last fall as a new sister company to the National Center for Defense Manufacturing and Machining (NCDMM), which has been dedicated to bringing new technology and processes to the defense industrial base since 2003. The expansion of that mission to new sectors evidences the extent of the promise that leaders in industry, government and academia alike see in digital transformation, as well as the urgency of enabling all manufacturers to share in that promise.

Related Content

Four Questions (& Answers) About Data-Driven Process Improvement at CNC Job Shops

How can shops can make informed decisions using data-driven feedback to improve shopfloor efficiency and profitability? And how will these technologies differ between high- and low-volume production?

Read MoreProcess Control — Leveraging Machine Shop Connectivity in Real Time

Renishaw Central, the company’s new end-to-end process control software, offers a new methodology for producing families of parts through actionable data.

Read MoreLeveraging Data to Drive Manufacturing Innovation

Global manufacturer Fictiv is rapidly expanding its use of data and artificial intelligence to help manufacturers wade through process variables and production strategies. With the release of a new AI platform for material selection, Fictive CEO Dave Evans talks about how the company is leveraging data to unlock creative problem solving for manufacturers.

Read MoreGive Job Shop Digitalization a Customer Focus

Implementing the integrated digital technologies and automation that enhance the customer's experience should be a priority for job shops and contract manufacturers.

Read MoreRead Next

4 Ways Eastec Evidenced Manufacturing’s Evolution

From tooling and workholding to Industry 4.0, the pursuit of new CNC machining opportunity united all who turned out for the 2021 event.

Read MoreAdding Part Traceability to CNC Machine Monitoring

Focusing on what makes money puts CNC machine monitoring data in context.

Read MoreRegistration Now Open for the Precision Machining Technology Show (PMTS) 2025

The precision machining industry’s premier event returns to Cleveland, OH, April 1-3.

Read More