Columns

5 Tool Setting Techniques

Each tool setting technique has merit, and it depends on where you are as a shop and the type of work you do, as cost and efficiency all come into play.

Read MoreEncountering Surface Finishes in the Everyday World

Surface measurement is becoming increasingly important to ensure proper performance of a manufactured product. Advanced surface measurement tools are not only beneficial in the manufacturing industry but also have unconventional applications.

Read MoreHow One Machine Shop Adopted (and Defined) a Four-Day Work Week

In an industry facing perennial shortages of skilled labor, shop owners must leverage every competitive advantage at their disposal in their efforts to attract talent. One small shop in Bridgewater, Massachusetts is experimenting with a new staff schedule that the owners say is already reaping major benefits: a four-day work week.

Read More3 Considerations for Revising Design for Manufacturing Efforts

When revising part designs, investigate the 3D CAD, the 2D drawing and the part’s functional requirements to determine which details should be tightened up.

Read MoreCommunity, Machines and the Open Road: A Tribute to Barry Rogers

Machine tool industry stalwart and friend Barry Rogers will be remembered for his passion, kindness and community spirit. A reflection on Barry’s remarkable career and the impact he had on countless individuals.

Read MoreA Height Gage in a CMM’s Skin

Modern electronic height gages are computer-based, touchscreen-operated systems that enable automated measuring routines, error correction and multiple probe offsets, much like a CMM.

Read MoreStrange But True: Odd Things That Happen With CNCs

These oddities in the way a CNC naturally behaves can help explain some rather unusual situations that may occur during machining.

Read MoreU.S. Navy Invests Heavily in Shoring Up Manufacturing Base

As part of its commitment to replace its aging submarine fleet, the U.S. Navy is investing heavily in building America’s manufacturing base, including free education and assisting suppliers in modernizing their facilities.

Read MoreWhen to Refurbish and When to Buy New

The choice between buying a new machine or refurbishing the current one will become clear after a thorough assessment of the machine.

Read MoreObscure CNC Features That Can Help (or Hurt) You

You cannot begin to take advantage of an available feature if you do not know it exists. Conversely, you will not know how to avoid CNC features that may be detrimental to your process.

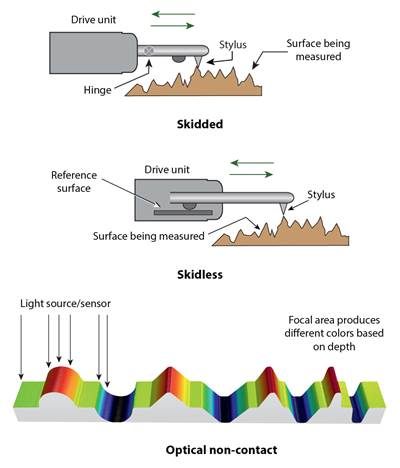

Read MoreCorrelation Between Contact and Non-Contact Surface Analysis Equipment Is Critical — Until It Isn’t

Understanding the differences between measurement methods means their discrepancies can be explained and used as an advantage to produce better correlation.

Read MoreThe Intersection of CMMC and Small- to Mid-Sized CNC Job Shops

The decision to gain or retain status as a defense supplier by pursuing CMMC compliance is especially difficult for small- to mid-sized machine shops, and the complexities and misperceptions tied to the program certainly aren’t helping. To break down those complexities, here are five key issues that small- and mid-sized job shops need to know about CMMC.

Read More