Standards Close the Loop

Artificial intelligence is an up-and-coming application enabled by the Industrial Internet of Things.

Share

Artificial intelligence is an up-and-coming application enabled by the Industrial Internet of Things. More specifically, the notion of self-aware machines or systems that can learn from their own environment and adapt on the fly is gaining wider acceptance as a feasible and desirable possibility. However, the seemingly mundane world of communication standards and protocols is playing a key part in this technology development, because it promises to fill gaps in the critical infrastructure that are still missing.

To begin, it’s important to grasp the value of self-aware machines by looking at some real-world cases. Machine tools already have, in fact, some capability for self-awareness. They operate as a collection of systems, subsystems, components and sensors that are linked together and centrally controlled. For example, a feature such as backlash compensation takes advantage of input from one component to calculate an adjustment that is fed back to the control of the component to eliminate an unwanted result. Likewise, the technology to make a real-time feedback loop for cutting tools is also in development. Vibration sensors feed data to a toolholder that can automatically make slight adjustments to avoid undesirable harmonics, which in turn reduces chatter, improves surface finish and increases insert life.

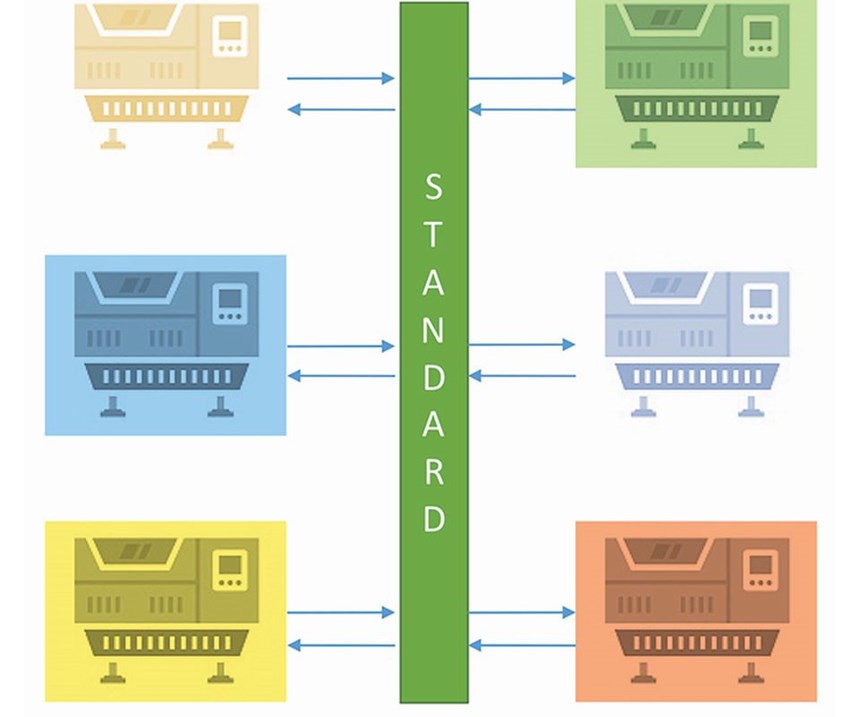

In theory, these current applications of self-aware equipment could soon be joined by much larger feedback loops. A part or assembly on the factory floor could carry metadata about itself and the equipment, designs and people that created it. The manufacturing enterprise software and radio transmitter components required for these feedback loops exist today, but gaps in connectivity are preventing solutions from functioning as intended. Communication standards are missing or incomplete, thus making the one-to-one connections and translations between components excessively complex.

Upstream from production, manufacturing engineers and the software companies that serve them are trying to figure out how to reduce design changes and rework. Input from machine tools, inspection data and other sources will eventually be available at the design phase to guide decisions, just as cutting tool libraries have now become an integral part of CAM software.

Similarly, finished parts will carry information about their service life with them. This will benefit operations to rework, repair or maintain them. This practice is the norm for many aerospace parts now, with sophisticated part genealogies required for FAA compliance. Promoting this trend is the continued decline in the cost of data acquisition and storage. However, developing the standards for defining data and its framework is still a hurdle to overcome. These standards are needed to link and relate different types of data from disparate components.

To assist in this transition, the MTConnect standard is changing in two major ways. First, it is expanding its sets of definitions to cover types of equipment not previously addressed. For example, the standard has been implemented for additive manufacturing and for lasers. In both cases, extensions to certain existing data items could be used for this purpose. These extended definitions are being brought into the official release of the standard through the Technical Advisory Group and its working groups. Second, MTConnect is establishing links to other standards and data models that already exist or are in development. Data on personnel, for example, are already well-defined outside of MTConnect. Data definitions for entities such as “operator” or “user” will allow MTConnect data to be associated in a useful way to data about performance, attendance, training issues and other “people factors.”

Many industries must work together to realize a future for self-aware manufacturing systems and artificial intelligence. Standards may seem tedious or esoteric, yet they are the glue that joins all the pieces together and helps technology move forward in a coherent and unified manner.

Related Content

5 Stages of a Closed-Loop CNC Machining Cell

Controlling variability in a closed-loop manufacturing process requires inspection data collected before, during and immediately after machining — and a means to act on that data in real time. Here’s one system that accomplishes this.

Read MoreDiving Deeper Into Machine Monitoring Data

Data visualization is the first step in using machine monitoring data, but taking it to the next level requires looking for trends within the data.

Read MoreReinventing a Precision Shop With a Data-Driven Mindset

When this machine shop lost 90% of its business within three months, a reinvention was in order. Here's how it survived after quickly falling on hard times.

Read MoreGive Job Shop Digitalization a Customer Focus

Implementing the integrated digital technologies and automation that enhance the customer's experience should be a priority for job shops and contract manufacturers.

Read MoreRead Next

Building Out a Foundation for Student Machinists

Autodesk and Haas have teamed up to produce an introductory course for students that covers the basics of CAD, CAM and CNC while providing them with a portfolio part.

Read More5 Rules of Thumb for Buying CNC Machine Tools

Use these tips to carefully plan your machine tool purchases and to avoid regretting your decision later.

Read MoreSetting Up the Building Blocks for a Digital Factory

Woodward Inc. spent over a year developing an API to connect machines to its digital factory. Caron Engineering’s MiConnect has cut most of this process while also granting the shop greater access to machine information.

Read More