Share

Grady Cope believes that digitalization leverages two key assets of Reata Engineering: A variety of automated production equipment such as this robotic loading/unloading station serving a Mazak Integrex, and youthful members of his workforce team, who bring a strong awareness of software integration and data sharing. Shown here are engineering interns, Darius Totah (left) and Adam Zaouague. Photo Credit: Reata Engineering

Today, all manufacturers face a plethora of options for digital technology to streamline the part production process. But where to begin? What “pieces” are the most important? What should a machining job shop do first?

Grady Cope, CEO of Reata Engineering and Machine Works in Englewood, Colorado, has an answer: start with the customer. Prioritize the digital automation that makes customer interactions as seamless as possible, then grow from there. Cope believes this is the best path to promote the profitability and sustainability of a job shop.

“Digital automation can make shop floor operations more productive, yet some technology is more directly related to achieving customer satisfaction than others,” Cope says. “So go after those systems first.”

For example, Cope recommends that a job shop put in an automated request for quote (RFQ) system and then a machine monitoring system or an updated ERP system if a current system is inflexible or resistant to integration. These recommendations are based on his company's transformation into what he considers an almost fully digitalized job shop. Cope says “almost” because the process of automation and digitalization is ongoing and open-ended.

Furthering The Digital Automation Journey

Reata Engineering was formed in 1993 with the purchase of a used mill and a lathe, both manual machines. The following year, the shop invested in its first CNC machining center. “In a way, that was the start of our journey to digital automation,” Cope recalls.

Reata Engineering currently employs 45 people in its 26,000 square feet of manufacturing and engineering space across two locations. A mix of five-axis HMCs and VMCs, multitasking machines, turning centers and Swiss-type lathes provide the core of the shop’s machining capability.

He says the constant goal over the years is to be a single-source precision machining and contract manufacturing partner. “Today, our capabilities range from design for manufacturing to prototype and beta development to production manufacturing and assembly to fulfillment and distribution,” he says.

Here are the top three digital capabilities that Cope says have proven to help a job shop provide strong service to customers, in the order that he thinks a job shop should consider implementing them.

Automated RFQ Systems Build Trust and Confidence

Based on his company's experience, Cope believes that an automated, digital RFQ system has the most promise for promoting customer relationships. He says that, although manufacturing is the prime occupation for Reata Engineering, the company is in the customer service business, explaining that it is rewarded for fulfilling a contract to provide a customer with the machined, finished and perhaps custom-packaged or otherwise value-added parts to agreed-upon specs and delivery dates. However, the commitment between the parties must be founded on mutual trust and confidence, which starts with the RFQ.

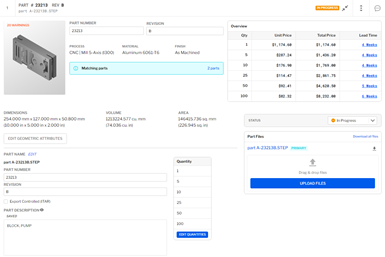

An automated quoting system such as Paperless Parts strengthens trust and confidence with prospective customers. Quotes prepared automatically by the system use a part model viewer and selectable options that help all parties reach an agreement quickly. Image Credit: Reata Engineering

With this goal in mind, Reata Engineering installed the Paperless Parts quoting system in the fall of 2020, becoming one of this software developer’s earliest users. Essentially, the system provides a framework for generating an acceptably accurate and timely quote using an intelligent pricing engine designed to interpret a customer’s CAD model. The system applies cost variables in the template configured by the shop to reflect its capabilities and constraints. Cope says it is possible to email a completed quote in a clearly arranged, ready-to-accept format in less than 24 hours.

The real strength of an automated quoting system lies in streamlined communication, Cope says. Questions that emerge on either side — customer or job shop — can be answered efficiently and precisely because the exchange relies on what both parties can see in the quoting system’s CAD model viewer. “No guesses no misunderstandings, no assumptions,” Cope says.

Equally important, the system includes an application for the shop’s computer network that enables the quoting and estimating staff to communicate with design engineers, CNC programmers, machinists and other personnel who have information critical to rapid and accurate quoting.

Because an automated, digital quoting system makes communication the basis for trust and confidence with customers, Cope sees it as the number one priority for digitalization. Moreover, setting an imperative for making communication as the basis for trust and confidence underlies the second recommendation for job shop digitalization: machine monitoring.

Problem Solving With Machine Monitoring

Collecting data directly from machine tools enables shop managers to track what is happening, literally moment to moment, on the shop floor. Is a certain machine cutting or not cutting? If cutting, is it cutting properly and efficiently? If not cutting, why is it idle? A machine monitoring system answers these and many other questions about machine and operator activity, using data gathered, reported and analyzed automatically.

“It's another method of communication,” as Cope characterizes it. And, like an automated quoting system, the value lies in promoting trust and confidence inside the company, he says.

In late 2021, the shop began installing the MachineMetrics monitoring system and completed the installation about three months later. At first, the system's dashboards displayed on screens in the shop area and on managers’ desktops helped spot opportunities to avoid or resolve bottlenecks, especially those arising from issues with fixturing and setup — a perennial concern for low-volume, high-mix shops such as Reata.

Cope says that this new level of communication strengthened trust and confidence throughout the manufacturing team. “Having machine data to point to is the best way to keep objective, straight-forward discussions focused on solving problems,” he says.

More importantly, the machine monitoring system enhanced the quoting and estimating process because real-time data from the shop floor can be checked against the capability and constraint variables built into the algorithms of the RFQ software. For example, the shop can evaluate whether moving a job to a machine tool with greater automation is warranted. Similarly, early warning enables the shop to check for possible programming errors or quoting inaccuracies and take timely corrective action.

With automated quoting and machine monitoring in place, Cope says the shop’s attention then turned to upgrading the shop's ERP system for shop scheduling. The system that had been in place for several years was serviceable but not easily integrated with the quoting and machine monitoring system. Finding a new system was the logical next step toward integrated, digitalized operation.

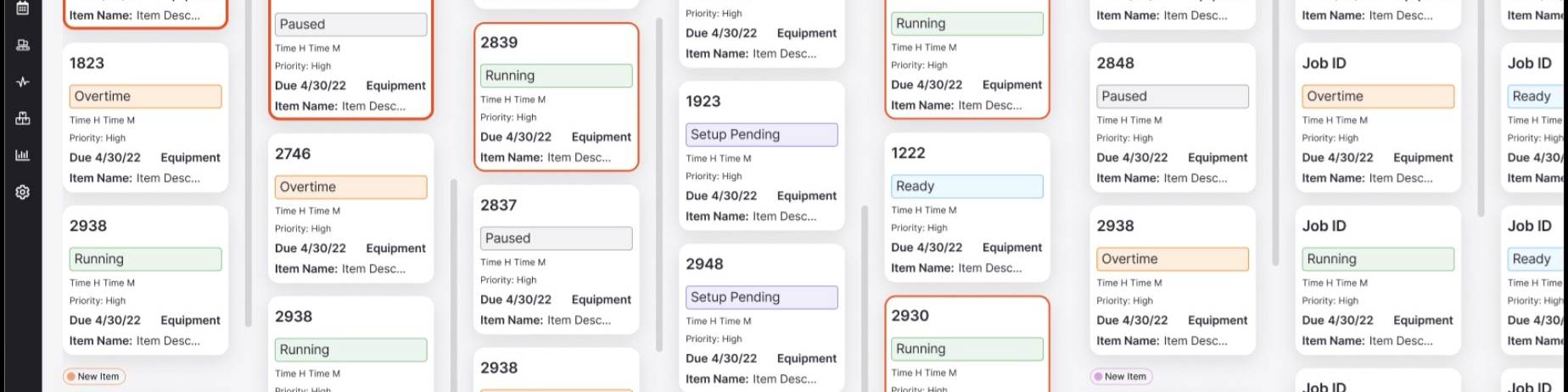

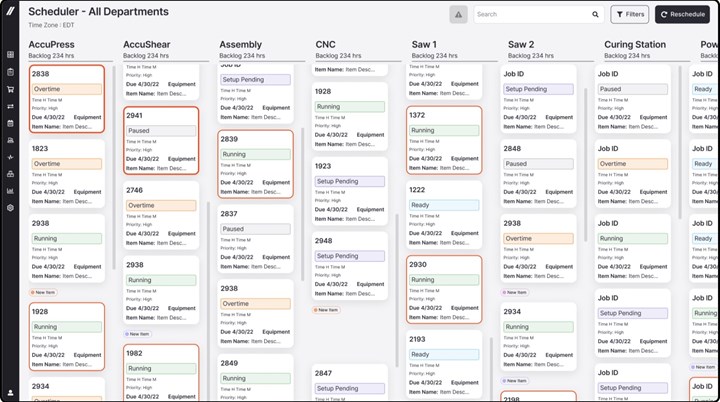

One of the most useful screens provided by Fulcrum's Automated Production Scheduling software enables Reata to drag and drop current job “tiles” to see the potential impact on part deliveries, a powerful tool for optimizing the shop schedule dynamically. Image Credit: Reata Engineering

Shop Scheduling Increases On-Time Delivery

Scheduling software should enable a job shop to make the best use of every hour of productive time on every machine in a shop, Cope says. A good scheduling system matches a shop's capacity to the customer’s jobs, and tracks their progress to help ensure they are completed on time. “The more efficiently and reliably we can do this, the better we can meet the level of service we want customers to expect from us,” Cope says. Obtaining and sharing critical information about production timeliness is key, he says.

The shop's choice for this was the Automated Production Scheduling software from Fulcrum. Installation began in the spring of 2023 and went live in June.

“All of the major benefits we were looking for are emerging as expected,” Cope says. One of the most important benefits is greatly reducing or eliminating paper on the shop floor. All the scheduling information that machine operators and supervisors need is transmitted electronically to PCs or tablets at each workstation. As job steps are completed, data is updated either automatically or (less frequently) by operator input and reported to the scheduling system, which in turn updates schedules in real time. Changes to due dates, quantities and other factors are available to managers immediately.

Being able to schedule jobs more precisely, update the schedule in real time and respond rapidly has improved the shop's already high on-time delivery record. “What we can see is that jobs are flowing more smoothly and that we are catching snags earlier when they are easier to resolve. When we see an issue that might impact a customer's expectations, we can communicate right away and explore options that are mutually acceptable, such as splitting a delivery,” he says. Because the new scheduling system is part of Fulcrum’s modular, cloud-based suite of applications, Reata Engineering has the option of installing additional modules such as inventory control and quality data management.

Application Programming Interfaces are Essential

Quoting. Machine monitoring. Scheduling. Cope considers these the three mainstays of digital automation of greatest value to a job shop in terms of service to the customer. Making sure these aspects of digital automation are adequately integrated, however, is vital to fully leveraging their benefits. This raises two issues for a shop moving toward digitalization: One is the challenge of sharing data among these systems for analysis and processing. The other is creating a centralized “business intelligence” platform for accessing, organizing and presenting the data that matters most.

Reata Engineering has addressed both issues, Cope says, offering this progress report: “Our quoting, machine monitoring and scheduling systems currently are talking to one another, but it has not been an entirely plug-and-play process, at least not when we began the effort in 2020,” he says. All three software developers recognized that offering interfaces that make it possible to share information is a strong selling point to job shop users. However, almost every installation entails a level of customization requiring considerable data coding and formatting by the IT staffs of all parties involved, including Reata’s.

Data exchange with the Fulcrum scheduling system has been the latest project, and here Cope notes that the well-developed application programming interface (API) that accompanied this software was a big plus. An API is the programming code that enables data to be shared among software products from different suppliers. Cope says that the API identifies what data to request and what processing it will receive so it can be delivered in an understandable and usable format to the receiving application. “The engineers, especially some of the youngest ones, who looked at Fulcrum’s API were impressed by its openness, completeness and thorough documentation. Their opinion was a key factor in its selection,” he says.

Interfacing applications has paid off. For example, when the machine monitoring system detects that unexpectedly long run times will cause a certain job to miss its goals, the scheduling system can use this report to recalculate delivery dates and make adjustments to the schedule to compensate or flag the issue for management attention.

The Big Picture — Integrating Shop Data Streams

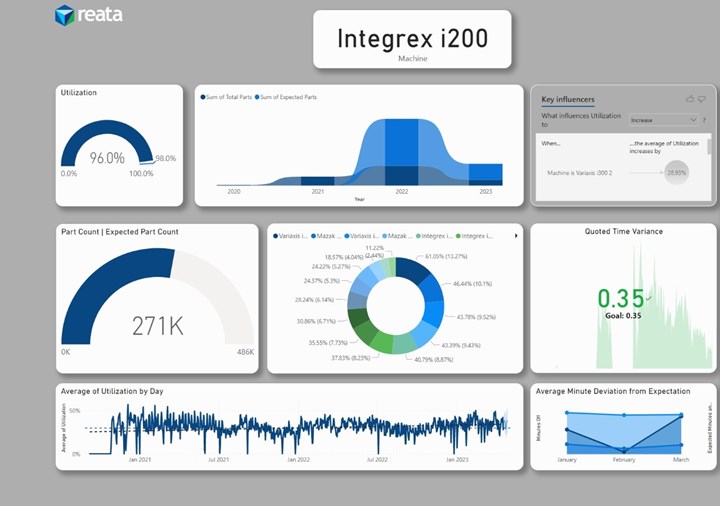

Even with the level of integration derived from interfacing quoting, machine monitoring and scheduling, Cope says that the need for a single platform that could make all of his shop’s data accessible and intelligible became apparent. “We wanted one screen on which we could display key reports, charts and graphs showing trends in our business activity and business results,” Cope explains.

Displaying summaries of key data from several applications on one screen is the essence of Power BI's capabilities. This screen, for example, gives managers a picture of one machine's contribution to the shop's overall effectiveness, the kind of business intelligence that improves decision making such as whether to acquire another machine like this one.

Image Credit: Reata Engineering

He believes that Microsoft Power BI (Business Intelligence) is the answer for Reata Engineering. Power BI is designed to facilitate the display and arrangement of data as a kind of universal dashboard of company activity and business metrics regarding profitability and sustainability. The shop has been implementing this platform since the fall of 2022. Currently there is one full-time engineer dedicated to building the connections that pull selected reports from databases and various software applications. The goal is to have the most relevant data visible as charts or graphs for interpretation at a glance.

If greater detail is needed, clicking on a graphic item will bring up more selections for further exploration. For example, data from the quoting system can be pulled up and queried to show indicators such as average order quantity, cost per part, process time per part and so on. Likewise, data from the machine monitoring system can be pulled up to show labor input, average setup time, scrap rates, value added per spindle or per machine operator and so on.

Cope says looking at these graphical displays lead to useful insights—the “intelligence” needed to make good decisions. For example, a particular concern at the moment is determining what machine tool automation to prioritize for future acquisitions. Whatever the choice, the decision to invest in the next machine will be backed by facts and figures.

Artificial Intelligence On the Horizon

Cope keeps in mind that the point of digitalizing and automating is to promote better customer service. He says that when you streamline operations with automation and digitalization in one area, you discover opportunities for automation and digitalization in the next most needed area. He likens this to a lesson learned from the lean manufacturing journey in its unending quest to reduce waste.

One item on the automation wish list is roboticized masking of parts for plating or finishing. As it stands, plugging holes and taping surfaces on workpieces is a manual process. “It is tedious and time-consuming, the kind of repetitious job that ought to be reserved for robots,” Cope says.

Artificial intelligence (AI) and augmented reality (AR) are two emerging digital technologies that Cope is watching most closely today. “I see AI helping our skilled people solve problems more readily and use their creativity more productively,” he says. “Likewise, I see AR helping talented newcomers get the training they need in an immersive, virtual experience that complements the younger generation’s familiarity with video gaming and similar graphical environments.”

The Next Level of Transparency

Circling back to the theme of trust and confidence based on communication, Cope ultimately wants digitalization to lead to sharing data with customers more effectively. Most likely, this initially will take the form of automatically reporting job status to customers who elect to receive these updates, he predicts. Other possibilities being explored include sharing metrology data so that a customer can apply selective assembly for tightly-toleranced complex assemblies.

Cope feels that digitalization makes this level of transparency both feasible and desirable, and that the contract manufacturing world is ready to make this jump. “We'll be ready and willing to do what it takes so that we and our customers can level up together,” Cope concludes.

Related Content

Using the Toolchanger to Automate Production

Taking advantage of a feature that’s already on the machine tool, Lang’s Haubex system uses the toolchanger to move and store parts, making it an easy-to-use and cost-effective automation solution.

Read MoreHow to Accelerate Robotic Deburring & Automated Material Removal

Pairing automation with air-driven motors that push cutting tool speeds up to 65,000 RPM with no duty cycle can dramatically improve throughput and improve finishing.

Read MoreCutting Part Programming Times Through AI

CAM Assist cuts repetition from part programming — early users say it cuts tribal knowledge and could be a useful tool for training new programmers.

Read More4 Steps to a Cobot Culture: How Thyssenkrupp Bilstein Has Answered Staffing Shortages With Economical Automation

Safe, economical automation using collaborative robots can transform a manufacturing facility and overcome staffing shortfalls, but it takes additional investment and a systemized approach to automation in order to realize this change.

Read MoreRead Next

5 Rules of Thumb for Buying CNC Machine Tools

Use these tips to carefully plan your machine tool purchases and to avoid regretting your decision later.

Read MoreBuilding Out a Foundation for Student Machinists

Autodesk and Haas have teamed up to produce an introductory course for students that covers the basics of CAD, CAM and CNC while providing them with a portfolio part.

Read MoreSetting Up the Building Blocks for a Digital Factory

Woodward Inc. spent over a year developing an API to connect machines to its digital factory. Caron Engineering’s MiConnect has cut most of this process while also granting the shop greater access to machine information.

Read More