Share

Pioneer Service Inc. uses spreadsheets with live data to keep track of its tool supply and demand. Photos courtesy of Pioneer Service Inc.

In 2012, Pioneer Service Inc. lost 90% of its business within six months.

With its usual business seemingly gone and no indication it would return, the machine shop needed to find and optimize a new niche to keep the doors open.

“Closing the doors and laying people off was not an option,” says Aneesa Muthana, CEO of Pioneer Service. So she turned to what she calls her — and everyone’s — best friend: YouTube. She scoured YouTube at night trying to figure out which direction to take the business.

There, she learned about Swiss-type machining and realized that was the direction to take the shop. It made sense because the staff was already familiar with working on small parts thanks to the years spent running Brown and Sharpe and Davenport screw machines in the Addison, Illinois, facility. Muthana gives a lot of credit to production supervisor Luis Hernandez for the transition. Hernandez would work Sundays and take his laptop home to teach himself how to program and set up a job with the new technology.

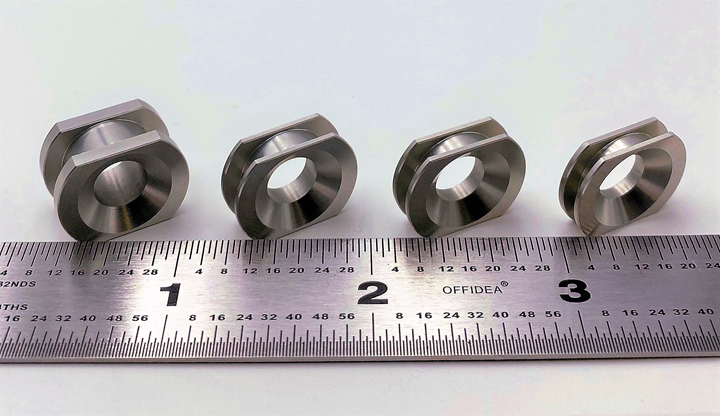

Pioneer Service precision machines parts for industries like aerospace, electric vehicles, sporting goods, oil, gas and more.

“It was extremely challenging just reinventing the company,” Muthana says. “I would see Luis on the shop floor on Sundays, and — I’ll never forget this — one day he looked at me and said, ‘When we didn’t have work and we were here cleaning and putting things away, you didn’t lay us off. You didn’t send us home. Now, it’s my turn. I want to learn and I want to give back.’”

Pioneer Service’s Swiss-type journey started with two Star CNC machines in July 2014. Fast forward to today and the shop has 31 Star machines on its shop floor with another 15 on order, and it now offers CNC turning and centerless grinding in addition to Swiss machining, using Horn as one of its tooling providers and a go-to resource for problem-solving solutions in the shop.

Pioneer Service’s Horn rep visits the business about once a month to check in and try to offer solutions to any problems the shop may be having. Pioneer Service is a high-volume environment that typically takes on jobs requiring 1,000 or more parts, serving a variety of industries like medical, aerospace, electric vehicles, oil, gas, sporting goods and more. It also makes millions of parts per year for Tesla.

While changes like the shift to Swiss-type machining were planned to compensate for the sudden loss of business, there was another, more happenstance change in Pioneer Service’s way of operating.

Seize the Data

Shortly after beginning the transition from manual screw machines to CNC and Swiss-type, Pioneer Service was approached by a small startup company that offered machine monitoring software. In early 2015, the company wanted to test out its software on one of the shop’s machines free of charge as a case study.

Pioneer Service obliged and communicated regularly with the company, with Muthana providing feedback on what data was most useful on dashboards and reports for understanding her shop’s strengths and weaknesses. With this feedback, the startup company would gain a better understanding of what shops would want and need from its software.

Once Pioneer Service realized the potential of machine monitoring software, it set up the software to display on machines, tablets and various monitors throughout the shop.

Pioneer Service didn’t go into this partnership with the goal of pairing the software with all of the shop's machines, but once it learned more about the data and had the opportunity to look at it to shape decision-making, Muthana decided that was the right move.

This move was well-received by some, and less so by others. Muthana recalls a former operations manager who pushed back on the idea due to the “Big Brother” skepticism that comes with the fear of upper management weaponizing the data.

“I would say it was intimidating to most people because it was like, ‘what is she doing with this information?’” Muthana says.

So, she made it a point to take the information and use it in meetings to explain what she was doing and how the machine shop uses the information, reassuring the staff that they wouldn’t get into trouble because of red numbers and various issues the data might show. Pioneer Service uses this data to spot ways in which it can support production by providing better tooling, raw material and training.

Muthana credits one of her younger operators and an engineer who enjoyed collecting and digging into the data with championing the effort to learn how to effectively use the software and implement it throughout the shop. And to further increase the buy-in to this data, Pioneer Service began distributing quarterly bonuses when certain performance goals are met.

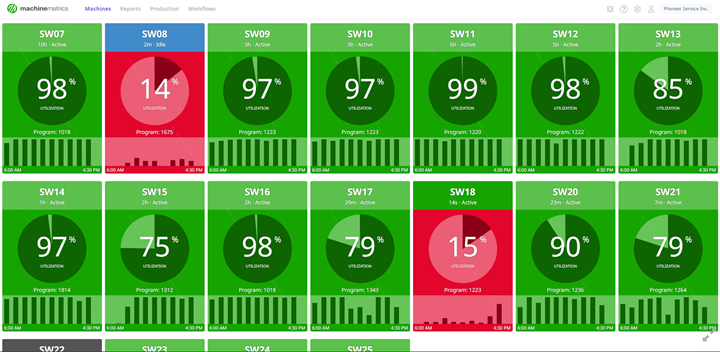

Pioneer Service has since parted with its first software provider on good terms, switching to MachineMetrics for its ability to integrate with Pioneer’s Global Shop Solutions ERP system.

One problem the machine data allowed Pioneer Service to spot was the consistency of tool breakage. With MachineMetrics offering data straight from the machine control, Pioneer Service can now collect and monitor production data to determine when tool failure is impending and replace the tool before failure occurs.

With this data on the shop floor, Pioneer Service can easily calculate and keep track of its overall equipment effectiveness (OEE) using various uptime, quoted time and actual cycle time statistics to calculate how well the shop is performing. The typical industry OEE figure is around 60%, while a suitable long-term goal is closer to 85%.

With the tools offered by its machine monitoring software, Muthana says Pioneer Service has increased its OEE on average by 15% year-to-year over the past four years and meets or exceeds that 85% target, citing increased awareness of tool life and visibility of the data throughout the shop on monitors, tablets and presentations as some of the main reasons for these improvements.

With MachineMetrics, Pioneer Service can quickly view various data points like utilization to calculate its OEE and determine the shop’s level of success.

An even bigger bottleneck in the daily process — until last year — was tracking the supply and demand of the shop’s tools to calculate what is in use and what quantities to order.

One of the machinists, John, had retired but returned part-time and was tasked with tracking this information. He initially printed out a spreadsheet and went from machine to machine, tracking what tools were in use, how much stock was on hand and how long tools were lasting. This task was taking an entire eight-hour shift with no automated data collecting.

When one of the process engineers, Oscar, joined the company, Oscar was tasked with finding a way to streamline the process. After a lot of Googling, he learned how to create macros in Excel that consolidate tool information into one spreadsheet. With this new setup, John only had to input the tool life, lot size and tool location, and the consolidated data then generated the demand calculation automatically, cutting the process down to about two hours.

Recently, manufacturing engineer Yousef Muthana says Scott Volk, vice president and COO of MetalQuest, visited the shop and made a suggestion that streamlined the process even further. Volk suggested connecting the document to Pioneer Service’s AutoCrib SQL database to have live inventory data every time the spreadsheet is opened. Now, Yousef says a process that used to take eight hours is done in less than 30 minutes. John’s time is freed up to use his four-hour shifts for other tasks like helping with job setups.

Pioneer Service’s niche is precision machining jobs of 1,000 or more parts.

What was once an old-school machining setup is now a shop full of data-driven processes and decision-making. And while going through all these changes and investing over $12 million in new equipment over the past decade for the 40-person, 25,000-square-foot shop, Aneesa avoided layoffs and never had to close the doors, a goal she had set as part of what she calls a people-first mindset. And with 15 new machines on order, Pioneer Service’s next step is moving into a new, 60,000-square-foot facility in April.

Related Content

Protecting Your Automation Investments

Shops need to look at their people, processes and technology to get the most of out their automation systems.

Read MoreManufacturer, Integrator, Software Developer: Wolfram Manufacturing is a Triple Threat

Wolfram Manufacturing showcased its new facility, which houses its machine shop along with space for its work as a provider of its own machine monitoring software and as an integrator for Caron Engineering.

Read MoreCan Connecting ERP to Machine Tool Monitoring Address the Workforce Challenge?

It can if RFID tags are added. Here is how this startup sees a local Internet of Things aiding CNC machine shops.

Read MoreDiving Deeper Into Machine Monitoring Data

Data visualization is the first step in using machine monitoring data, but taking it to the next level requires looking for trends within the data.

Read MoreRead Next

6 Tips for Training on a Swiss-Type Lathe

There are nuances to training a person to effectively operate a Swiss-type lathe. Derek Korn, Production Machining’s editor in chief, shares suggestions from a CNC machine shop.

Read MoreHow to Start a Swiss Machining Department From Scratch

When Shamrock Precision needed to cut production time of its bread-and-butter parts in half, it turned to a new type of machine tool and a new CAM system. Here’s how the company succeeded, despite the newness of it all.

Read MoreUnderstanding Swiss-Type Machining

Once seen as a specialty machine tool, the CNC Swiss-type is increasingly being used in shops that are full of more conventional CNC machines. For the newcomer to Swiss-type machining, here is what the learning curve is like.

Read More