Turn-Mills 101

Turn-mills are a type of multitasking machine that can shorten cycle times and help facilitate lights-out machining for two common machining types.

Share

Live-tool CNC lathes may not match the flexibility of full turn-mills, but they can still machine parts impossible for traditional lathes. In this case, Chick Machine Company used the lathe to machine a square part.

Turn-mill machines are a type of multi-tasking machine capable of both rotating-workpiece operations (such as turning) and rotating-tool operations (such as milling and drilling). They enable users to machine workpieces complete on a single piece of equipment—increasing accuracy by reducing setups and positioning adjustments, decreasing footprint compared to dedicated machines for each operation and reducing backlog waiting for different machines to become available on the shop floor.

Adoption of these machines increased heavily during the 2010s, a change that Modern Machine Shop’s Peter Zelinski credits to two developments. First, CAM software and postprocessors have caught up with these machines and can now reliably run them. Second, more shops have become interested in them as a means of facilitating automation.

Over the past decade, programming and control software advancements have gone beyond basic compatibility for turn-mills. Some systems use AI and machine learning in conjunction with digital twins, optimizing tool paths on offline testing grounds to reduce cycle times and eliminate potential crashes. Ongoing efforts to develop powerful postprocessors that limit the need for G-code editing should also lower the programming entry barrier for turn-mills.

As for shops becoming more interested in using turn-mills for automation, surveys from Gardner Intelligence’s Top Shops program show that the best predictor of whether a shop is likely to conduct light-out machining is whether that shop uses a turn-mill machine — followed by whether it uses a Swiss-type lathe, twin-spindle turning machine or twin-turret turning machine.

Lathe or Mill?

Many turn-mill machines are based on lathe designs, with the milling spindle more supplementary. This setup evolved from live-tool lathes, which use driven spindles that mount on a tool gang plate or turret to mill flats and drill holes.

The best predictor of whether a shop is likely to conduct light-out machining is whether that shop uses a turn-mill machine.

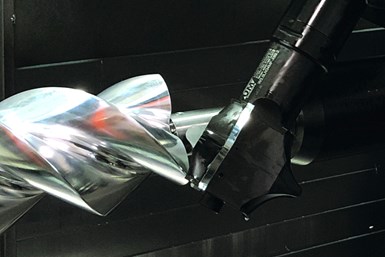

Another common form of turn-mill, B-axis turn-mills, more closely resembles a mill, but offers both five-axis milling and turning functionality. The turn-mill’s rotating milling head can machine parts held in the spindle or subspindle from many different angles. These parts don’t need to be the round parts of turning, either, with the B-axis flexibility enabling processing of fully prismatic parts or machine-contoured parts.

B-axis milling spindles open the door for a wide variety of machining operations, including complex contouring operations for turned parts.

These B-axis turn-mill platforms can perform simultaneous milling and drilling operations, as well as more complicated maneuvers such as pinch turning, skiving, contoured turning work and “turning milling,” where instead of feeding a static, single-point turning tool down the Z-axis, a spinning milling tool is moved down the part to “turn” the diameter. These machines are also good at creating big, shaft-like components that need milled features, such as large crankshafts.

More traditional twin-spindle and dual-turret turn-mill configurations can also improve performance, but may require synchronization of separate part programs running simultaneously, lest workpieces or spindles collide. Swiss-type machines with B-axis milling spindles have also become larger players in the turn-mill field, especially after the debut of automatic toolchangers and full-power B-axis spindles expanded their audience from shops working with small-diameter barstock to shops working with larger parts.

Tips and Tricks

Turn-mill users should follow a few workholding and parts loading best practices to optimize productivity.

When using a subspindle in conjunction with a bar feeder, the subspindle grabs the end of the bar and pulls out the length needed for the next part. As the subspindle will be more precise in pulling out the stock than the bar feeder is at pushing the stock in, relying on the subspindle for positioning will improve the final results for high-tolerance parts. Also, once the parting tool severs the finished part from the barstock, have a parts catcher ready so the turn-mill’s subspindle can drop the workpiece and make room for the next part.

If using automatic subspindle transfer, use three-jaw or dead-length collet chucks. If a collet or chuck moves in or out slightly, pushing or pulling on the workpiece when clamping, this unwanted motion could easily mar the workpiece.

Related Content

Cutting Part Programming Times Through AI

CAM Assist cuts repetition from part programming — early users say it cuts tribal knowledge and could be a useful tool for training new programmers.

Read MoreFour-Axis Horizontal Machining Doubles Shop’s Productivity

Horizontal four-axis machining enabled McKenzie CNC to cut operations and cycle times for its high-mix, high-repeat work — more than doubling its throughput.

Read MoreWhich Approach to Automation Fits Your CNC Machine Tool?

Choosing the right automation to pair with a CNC machine tool cell means weighing various factors, as this fabrication business has learned well.

Read MoreInside the Premium Machine Shop Making Fasteners

AMPG can’t help but take risks — its management doesn’t know how to run machines. But these risks have enabled it to become a runaway success in its market.

Read MoreRead Next

5 Rules of Thumb for Buying CNC Machine Tools

Use these tips to carefully plan your machine tool purchases and to avoid regretting your decision later.

Read MoreBuilding Out a Foundation for Student Machinists

Autodesk and Haas have teamed up to produce an introductory course for students that covers the basics of CAD, CAM and CNC while providing them with a portfolio part.

Read MoreRegistration Now Open for the Precision Machining Technology Show (PMTS) 2025

The precision machining industry’s premier event returns to Cleveland, OH, April 1-3.

Read More