Share

Automation is the present of manufacturing.

Even without robots, pallet changers or other obvious forms of reducing manual labor, competitive manufacturers find ways to accomplish more with fewer people. One example is the use of machines that combine multiple operations in a single platform. However, the tradeoffs involved in combining processes can result in equipment that is just as specialized as the dedicated machinery it replaces.

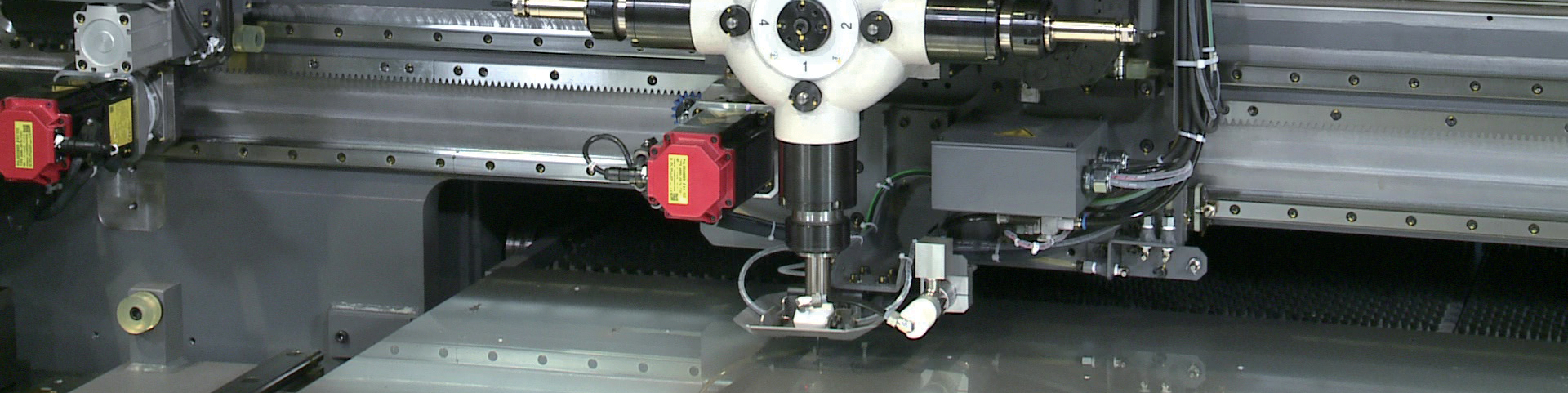

Consider the Advanced Hybrid Laser, a laser-fabrication system from Murata Machinery (Muratec) that combines laser-cutting, forming and tapping capabilities into a single multifunction machine. Flat, sheet-cut parts with numerous formed features and threaded holes constitute a broad category of work. However, Jeff Tyl – Muratec National Sales Manager, Aftermarket and Fabrication – says designers also had a specific application in mind: panels for electrical housing components manufactured for the HVAC, medical and lighting industries.

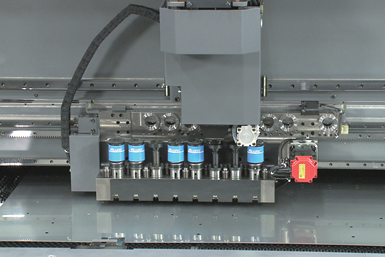

Here we see the tooling for the punching station. The machine has the capacity for eight tools, with up to 46 using optional tool changers. Photo Credit: Muratec

Automating With Specific Parts in Mind

Electrical housing components have numerous features that need stamped into the metal, as well as holes that need threaded for fasteners. For materials a half-inch and thinner, the laser will cut all interior holes and transfer the material for forming and tapping while maintaining positional accuracies with use of fixed material workholding. For larger materials, it can be used as a stand-alone fiber laser where workholding is not needed. Once in the forming and tapping station, the machine can use up to eight tools – 46 with a tool changer – to form the material into shape prior to tapping. “Before, someone would have to position it in the laser, then transfer the part to a forming machine, then finally transfer over to tapping,” Tyl says.

While the machine has a relatively large footprint, various manufacturers of flat parts that require secondary operations could benefit from it. In fact, Muratec has already agreed to develop processes for medical parts, Tyl says, adding that the machine is also great for parts that require contouring. However, electrical housings are ideal for it because the metal is thin and the parts require secondary processes.

“This machine is the first of its kind that I’m aware of.” – Jeff Tyl, Muratec

“If you look at a hybrid machine, be it a plasma punch or a punch laser or what have you, there is always a limitation,” says Tyl. “With the Advanced Hybrid Laser, that limitation is the tonnage of the press.” Specifically, the press can achieve only five tons each of upward and downward pressure – which means it is suitable for material at 12-gage thickness or thinner. “It really finds its niche in materials that require quite a bit of tapping and maybe some counter sinking,” says Tyl.

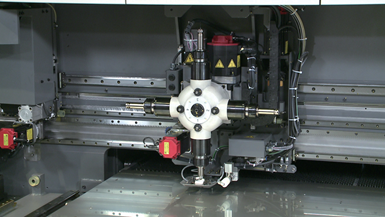

The tapping station has four separate spindles for tapping holes. When using particularly thin parts, holes must be extruded at the forming station to create the space required for tapping. Photo Credit: Muratec

Additionally, forming before tapping is generally a requirement for thinner parts, including panels for electrical housing components, Tyl says. “It’s important to form before tapping especially thin sheets because they lack the thickness required to tap,” he explains. “So the tool has to extrude the metal up or down to provide the space to cut threads.” The tapping system uses independent servos to generate the cutting forces.

Finally, Tyl says potential users should consider the need for new tooling. “This machine is first one of its kind that I’m aware of. No one’s current tooling will work with it,” he explains. “However, Mate and Murata will both manufacture tooling.”

In manufacturing, there will always be tension between specialized and generalized approaches to automation, and it is unlikely either approach will ever completely overshadow the other. The tradeoffs inherent to combining processes on one platform can narrow a machine’s application range, but within that niche it can outperform generalized approaches, as this hybrid machine demonstrates.

Related Content

Managing Coolant with Skimmers, Refractometers and More

Bacteria-infected coolant harms machines and sickens machinists. Coolant management technologies like skimmers and automated systems counter this tendency.

Read More3 Ways Artificial Intelligence Will Revolutionize Machine Shops

AI will become a tool to increase productivity in the same way that robotics has.

Read MoreFour-Axis Horizontal Machining Doubles Shop’s Productivity

Horizontal four-axis machining enabled McKenzie CNC to cut operations and cycle times for its high-mix, high-repeat work — more than doubling its throughput.

Read MoreInvesting in Automation, Five-Axis to Increase Production Capacity

To meet an increase in demand, this shop invested heavily in automation solutions and five-axis machines to ramp up its production capabilities.

Read MoreRead Next

5 Rules of Thumb for Buying CNC Machine Tools

Use these tips to carefully plan your machine tool purchases and to avoid regretting your decision later.

Read MoreBuilding Out a Foundation for Student Machinists

Autodesk and Haas have teamed up to produce an introductory course for students that covers the basics of CAD, CAM and CNC while providing them with a portfolio part.

Read MoreSetting Up the Building Blocks for a Digital Factory

Woodward Inc. spent over a year developing an API to connect machines to its digital factory. Caron Engineering’s MiConnect has cut most of this process while also granting the shop greater access to machine information.

Read More

.jpg;maxWidth=300;quality=90)