-

SPONSORED

-

-

-

-

-

MMS Blog

Don't Touch That Tool

Tool measurement is critical to the metalcutting process. Exact knowledge of a cutter’s length, diameter, even profile, and the ability to measure and monitor these dimensions over time, can reduce variability and help optimize the process. Here’s a look at how non-contact tool measurement and breakage detection benefit your metalcutting process.

Read MoreAn Approach To Boosting Shop Production Capacity

The increased availability of modular manufacturing cells has added another means of increasing a shop’s capacity. This article looks at a practical approach to evaluating when and how much automation is appropriate for a shop.

Read MoreWho's Counseling Whom?

How to make manufacturing attractive to career guidance counselors and parents is a challenge. Nobody has all the answers.

Read MoreProgramming To The Machine's Reference Position

Almost all current model CNC machine tools have a special reference position. For machines having Fanuc or Fanuc-compatible controls, this special position is called the zero return position.

Read MoreTroubleshooting Your Way Oil System

An expensive lesson that many shops learn too late is that the automatic oil system on their CNC machine tool may not be completely automatic. Since the automatic oil system is designed to give a warning when the oil tank is empty, many machinists simply assume all is well if the alarm doesn't go off.

Read MoreThe Other Angle On Five-Axis Machining

Machine complex prismatic parts efficiently on low-cost machining centers. This shop embraces five-axis machining—the kind that features a five-figure price tag.

Read MoreScamming The Scammers

According to the Small Business Administration (SBA), there are over 24 million small businesses in the Unuted States, and the number is growing by almost a million a year. At the same time, the number of Internet scams is increasing markedly.

Read MoreTrends In EDM

Electrical discharge machines, both wire and ram type, have undergone rapid improvements in capability, economical operation, speed and flexibility. New applications are continually emerging as shops discover the advantages of this process.

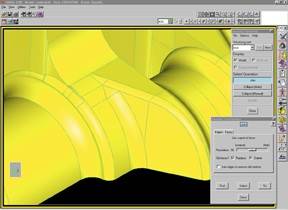

Read MoreTool Path Strategies For High Speed Machining

CAD/CAM features can be key to realizing effective High Speed Machining.

Read MoreThe Case For Additive Technology In EDM

Producing fine finishes on EDMed surfaces has long been a goal, especially for mold and die shops that operate ram-type electrical discharge machines. Lately, there has been renewed interest in using additives in the dielectric oil to achieve ultra fine finishes with graphite electrodes without excessive burn times.

Read MoreMaking Sense Of Model Data

Designs often arrive incomplete downstream. There may be no changing that. But these tools can reduce the amount of time spent on reworking customer models.

Read MoreImproved Spindle Cuts Cycle Time

Cutting speeds of 500 inches per minute are a reality with this new 15,000 rpm spindle system for high speed machining.

Read More