An Approach To Boosting Shop Production Capacity

The increased availability of modular manufacturing cells has added another means of increasing a shop’s capacity. This article looks at a practical approach to evaluating when and how much automation is appropriate for a shop.

Share

What’s the most effective way of adding assets to increase shop production capacity? The traditional way is through the purchase or lease of additional machine tools, but that may not always be the best way. Throughput and piece cost reduction should also be parts of the equation.

One approach that considers throughput and cost reduction is the use of palletized workholding systems, and, as needs dictate, progression to flexible machining cells. This approach offers advantages that go beyond the simple productivity gains offered by putting more machine tools online.

Reducing Non-Value-Added Time

Pallets, or more specifically, pallet changing systems, significantly reduce non-value-added time caused by machine setup. For example, a manually operated two-pallet changing system can reduce machine setup downtime by allowing load and setup operations to be performed on the off-line pallet while work is being machined on the pallet clamped to the machine table.

When the machining cycle ends, pallets can be easily switched, the machined workpiece removed, and a new setup started. Combined with common workholding devices, such as vises and clamps or modular fixtures rather than custom fixtures, a palletized system can significantly reduce part changeover time and extend the flexibility of the machining operation. The manual system can also be enhanced with additional pallets so that repeat setups can be stored and delivered to the machine when needed.

The Goal: Maximizing Spindle Utilization

Pallet changing systems, both manual and automated, are often associated with long production runs; however, because they allow off-line setup, they are very effective for short runs, since they maximize spindle utilization.

Improving spindle utilization is a key objective in any type of automatic work handling or work changing system. Surveys indicate that machine tool utilization is generally in the 25 to 35 percent range, which is 15 to 21 minutes per hour. An automated pallet changer allows operator load/unload times to proceed in parallel with machining time, improving spindle utilization and increasing throughput.

Spindle utilization and throughput increase even more by combining a fixtured tombstone with a twin-pallet changer. Assume a 30-minute cycle time for one completed part. In this example, 15 tools are required per part during the 30-minute cycle, and there is a 10-second, metal-to-metal tool change time.

That’s a total of 150 seconds or 2.5 minutes per part. When combined with tool dominant programming techniques, tombstone fixturing of eight parts on a twin pallet system can amortize tool changes, saving 2.5 minutes per part. For each 30 minute cycle, 2.5 minutes represents 8.33 percent more spindle utilization, and that’s 8.33 percent for each part on the tombstone.

Combining pallet changing systems with tombstone fixtures can also dramatically compress “floor-to-door” time when a ship set approach to scheduling and programming is used. For example, batch processing eight parts that make up a ship set 20 at a time takes a half day, or four days to complete one ship set. Setting up tombstones so that all eight parts are programmed at one time allows a complete ship set to be produced in a half day.

When is a pallet changing system the right choice? The answer is whenever operators spend more time setting up a job than they do running it. Parts best suited for a palletized workholding/work handling system are small to medium sized prismatic parts.

Pallet changing systems can be fitted to virtually any type of production machine, including measuring machines and vertical and horizontal machining centers. Vertical machining centers are generally limited to a two-pallet changing system. Horizontal machining centers are not limited in the number of pallets that can be installed and can easily be expanded to flexible, multi-machine cells with the addition of pallet transporters, load/unload stations and a central controller.

Taking A Closer Look At Flexible Manufacturing

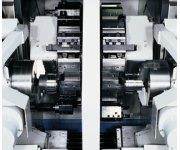

Flexible, cellular manufacturing offers even more production and throughput efficiencies than pallet changing systems. A cell can be a single machining center with an automated work handling system, or it can be a close grouping of machines connected by an automatic work handling system.

Whether a single machine or several machines, a cell is characterized by its ability to completely produce a workpiece so that the entire processing sequence is compressed in terms of space and time. This “Start-a-Part/Finish-a-Part” processing concept reduces the overall flow time required for the complete machining operation.

A properly designed cell can reduce part travel time around the shop and reduce manufacturing staging time, or in-line queue time. In effect, a cell becomes a manufacturing solution configured with the type and quantity of equipment needed to meet specific production requirements, whether they be high volume with low variety, low volume with high variety or varying volume with high variety.

What are the benefits of flexible manufacturing using the cell approach? Certainly improved part throughput. The primary advantage of cellular manufacturing is that automated pallet delivery keeps the spindle in the cut. In most cell applications, spindle utilization averages 90 to 95 percent.

Improved resource utilization is another advantage. Cellular manufacturing reduces part travel, and because of that, improves operator utilization by up to 50 percent. Because fixtures can be shared across multiple machines, fixturing costs also go down.

Reduced labor costs are also possible with cellular manufacturing. Because operators can control multiple machines, direct labor costs go down, and operators can be used in other value-added tasks. Cellular machining operations continue the cutting process through breaks and lunch, and they can operate unattended or lightly attended during off shifts. For example, with the addition of a cell, shops running two 10-hour shifts per day can run the remaining four hours unattended for full, 24-hour-per-day operations.

Moving Away From Sequential Processing

Generally, a cell approach is considered as a replacement for station-style, operation-oriented manufacturing. Sequential, manual movement and part flow characterize this style of manufacturing. Operation-oriented manufacturing is usually operator intense at each station and offers a limited variety of processing capabilities and setup flexibility. It is basic manual transfer manufacturing.

A cell approach offers the flexibility of process-oriented manufacturing. It features an automated part/pallet delivery system and a pool of online fixtures that are already set up.

It offers high variety and varying volume capability and features computerized workload and process management, pre-staging and automatic job execution. Redundancy, or randomness, is also an important feature of cellular systems.

Since processing is not sequential, parts can be routed to any available machine in the cell. The cell can also be set up so that all machining operations can be performed on one machine. As an added benefit, cellular, process-oriented, manufacturing is less direct-labor intensive than operation-oriented manufacturing.

Accounting For Unaccounted Costs

In a typical shop, part movement and in-queue times are the largest uncounted cost items. Parts can spend as much as 95 percent of processing time being moved or in-queue.

This time is usually taken up by waiting for raw goods inventory, moving parts from machine to machine, waiting for parts at each station, waiting for finished goods inventory, and inspecting the same features multiple times. Sequential production does not maximize throughput.

Because of work handling downtime, sequential manufacturing also does not provide the most efficient spindle utilization. For example, a typical four-operation sequential part processing application might have individual machine uptimes of 95, 94, 95, and 96 percent. But, when the four processes are combined (0.95 × 0.94 × 0.95 × 0.96), the result is 81 percent uptime.

Capital utilization is another concern in sequential operations. In the same operation, assume an average machine utilization of 64 percent. To determine the capital utilization, multiply average machine utilization by uptime by typical efficiency (0.64 × 0.81 × 0.80 = 41 percent). Examples vary widely by shop and by application, but the message is nonetheless clear. Because of time wasted in part movement and in queues for operations, sequential operations create inefficiencies that are difficult to overcome simply by adding more equipment and working harder.

When Is Cellular Machining Right?

There are certain symptoms that indicate the need for a cell. For example, does your shop operate with a progressive, dedicated station-style of manufacturing, typically producing too much work-in-progress identified by partially machined parts being transported all over the shop? Do the parts spend more time in non-value-added time traveling between operations than being machined? Do production requirements change faster than your shop can react? Are your parts plagued with engineering changes? Are your tooling costs too high? Do you purchase multiple machines to produce the same part or part families because setup time severely limits machining time and throughput?

If the answer is yes to any of these questions, then a cell arrangement may improve operations. Just as with palletized workholding systems, small to medium sized, prismatic parts—the types normally considered for horizontal machining center applications—are the ideal candidates for cellular manufacturing.

The first step in determining if a cell is the right approach for you is to perform an asset analysis. The asset value of any machining operation is a total of inventory and capital equipment.

The proper weighting between the two determines shop profitability. For example, each dollar in inventory increases expenses, costing as much as, or more than, 37 cents per year in taxes, lost revenue on inventory dollars, floor space cost and obsolescence.

On the other hand, dollars invested in capital equipment decrease expenses. Each dollar invested in capital equipment can produce an ROI of more than 33 cents per year due to investment tax credits, reduced direct labor costs, depreciation and better quality parts.

Consequently, each asset dollar shifted from inventory to capital equipment has the potential to produce 70 cents more profit per year. Machining cells replace stand-alone machines at ratios of up to four-to-one, making them extremely cost effective capital investments. A cell arrangement can be an efficient means of capital equipment expansion that has the added advantage of providing a highly flexible manufacturing capability that will give shop owners the ability to take on a wider variety of work.

Not All Of The Benefits Are Quantitative

There are advantages to cellular manufacturing that go beyond dollars and cents. For example, cellular manufacturing often fosters a team spirit where employees work together rather than as individuals responsible for the operation of a single machine.

Cells also optimize information retrieval through relational databases. Remote access through various interface options allows supervisors to call up status displays, generate reports, import/export NC programs, review tool data, workloads and routes, and exchange messages with operators from any PC.

It’s clear that any shop seriously considering increasing its capacity should investigate pallet changing systems and machining cells. A careful analysis of setup and queue times, capital utilization, direct labor rates and work-in-progress inventory could be all of the justification you need to open up a wide new world of possibilities. MMS

About the author: John Wiese is Industrial Equipment Marketing Director at Cincinnati Machine (Cincinnati, Ohio).

Related Content

Which Approach to Automation Fits Your CNC Machine Tool?

Choosing the right automation to pair with a CNC machine tool cell means weighing various factors, as this fabrication business has learned well.

Read More3 Ways Artificial Intelligence Will Revolutionize Machine Shops

AI will become a tool to increase productivity in the same way that robotics has.

Read MoreCutting Part Programming Times Through AI

CAM Assist cuts repetition from part programming — early users say it cuts tribal knowledge and could be a useful tool for training new programmers.

Read MoreSame Headcount, Double the Sales: Successful Job Shop Automation

Doubling sales requires more than just robots. Pro Products’ staff works in tandem with robots, performing inspection and other value-added activities.

Read MoreRead Next

High Automation for Low Volume

Many people think flexible machining cells are for high production, but this shop finds just the opposite. Here's how they've grown their cell to meet the needs of their work.

Read MoreDispelling Small Machine Shop Myths

Many job shops start in a garage with a used mill and a manual lathe. The owners of this Utah job shop took a different tack. Along the way to a very successful business, they've debunked a bunch of myths commonly held about job shops.

Read More