Share

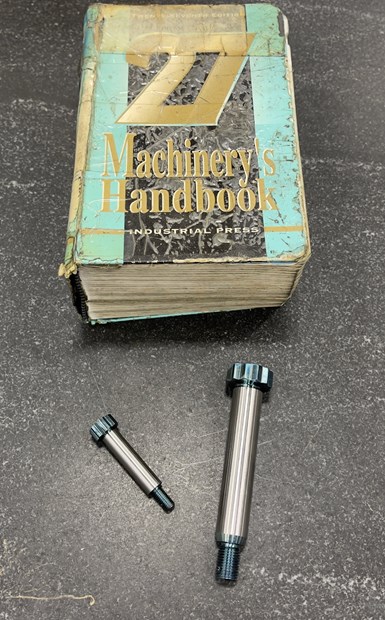

Shear screws and shear pins are machined parts engineered with a weak point that snaps, or shears, when met with a predetermined force or pressure. In one function, they are the mechanical equivalent of an electric fuse — sacrificial parts that safeguard other parts or systems in a machine. But shear screws can also serve as conditional safeguards that prevent the operation of a mechanism until a pressure threshold is achieved. In the oilfield services industry, when a hydraulic pump reaches a certain depth and meets a predetermined pressure, the shear screw snaps and allows the equipment to engage.

To the oil and gas industry, shear screws are critical parts for drilling and fracking operations. But to Shamrock Precision, a family-owned machine shop that has been manufacturing shear screws since the 1990s, they are critical to the success of the company and the livelihood of its employees.

Shamrock Precision has been manufacturing shear screws since the 1990s, and recently invested in several Swiss-type machines and a new CAD/CAM system to help ramp up production. All photos by Modern Machine Shop unless noted.

“Shear screws are the name of the game for Shamrock Precision,” says Corbin Embrey, the company’s second-generation owner and CEO. Until recently, Shamrock had been relying on conventional CNC lathes to produce several varieties of screws and fasteners. In 2017, when the oil and gas industry rebounded after a downturn and demand for shear screws started to skyrocket, Shamrock began to reevaluate its bread-and-butter product. As Embrey saw the opportunity to grow the business, he posed what sounds like a simple question: “How can we cut production time for these parts in half?”

Figuring out the answer to this question would be a central preoccupation at Shamrock for the next four years.

A new, automated, multi-axis/multi-spindle machining process would offer half of the solution. The other half would rely on software — a new CAD/CAM platform with which the company had no experience — and the ability of Shamrock programmers to master its key features.

It has been five years since Embrey posed his question, and the company has largely achieved its goal. During a visit to the shop earlier this year, I learned how they did it.

Shamrock launched its Swiss department in 2017. The company began using SolidCAM for its Swiss-machined parts in 2021, a transition led in part by (from L to R) Rob Holeman, Corbin Embrey and Chad McElroy.

A Reputation at Stake

The first part of the solution arrived in 2017 in the form a Marubeni Citizen-Cincom A20 Swiss-type lathe. Shamrock’s shear screws — machined from a variety of materials including Inconel, stainless steels, brass and aluminum — range in size from 0.125 to 0.875 inch, with threads tolerances as low as 0.0005 inches. They are in many ways ideal parts for Swiss-type machining, and the company was ready to invest heavily in capital equipment — if it meant meeting customer demand and cementing Shamrock’s reputation a top supplier to the oilfield services industry.

Shamrock Precision has recently diversified its customer base, taking on aerospace and defense projects and investing in five-axis machine tools. But shear screws, bolts and fasteners remain its staple product.

With the decision to create a new Swiss department in place, two obstacles remained: The first reason — and the main reason that Shamrock had not invested in Swiss up to this point — was that no one at the company had experience with Swiss-type machines. The company's CNC programmers were writing their own G-code programs by hand, a labor-intensive and time-consuming operation for multi-spindle, multi-axis machining. By 2020, it became clear that cutting production time in half would require software and offline programming to keep the machines running.

One of the recruits Embrey hired to run the new Swiss department was Rob Holeman, a journeyman machinist and engineer who had programmed a wide variety of CNC lathes and mills, and had experience with several CAD/CAM platforms — including SolidWorks, with which he was particularly experienced. And after researching several CAM platforms, Shamrock selected SolidCAM for its Swiss department partly because of its integration with SolidWorks’ CAD system.

The associativity between SolidWorks and SolidCAM proved to be vital when programming segmented threading operations, Holeman says. On a Swiss machine, screw threads must be machined in segments that are shorter than the length of the machine’s guide bushing, which means the toolpaths for longer threads have to be split into segments. By using SolidWorks as a CAD platform, Holeman was able to determine the exact starting and stopping points for each segment through the creation of sketch geometry in the CAD file. SolidCAM then uses that sketch geometry to help match the tool pitch at the start and end point of each threading pass. The result is a long, continuous thread with no cross threading or overlap.

The fact that SolidCAM is nested within SolidWorks allows the CAM to associate toolpaths for each machining operation to the CAD models in real time. In other words, when Holeman updates a model in SolidWorks, SolidCAM updates the toolpath for the part simultaneously. “No other software I've used had done that,” Holeman says. “You would actually have to go in and create a flat pattern for the lathe. Now you go in and you set your coordinates, which is nothing more than touching a diameter. It then automatically populates your target and your geometry. It’s instant.”

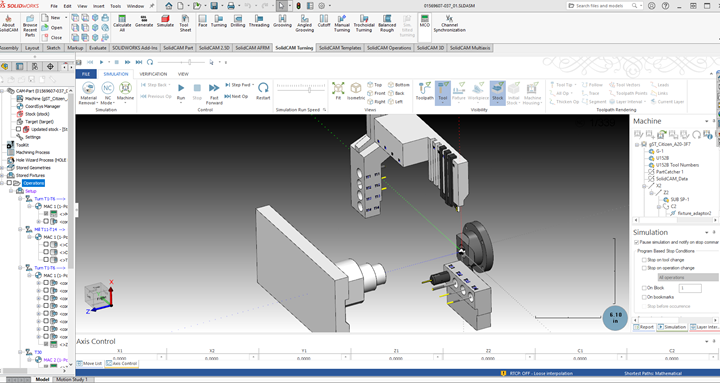

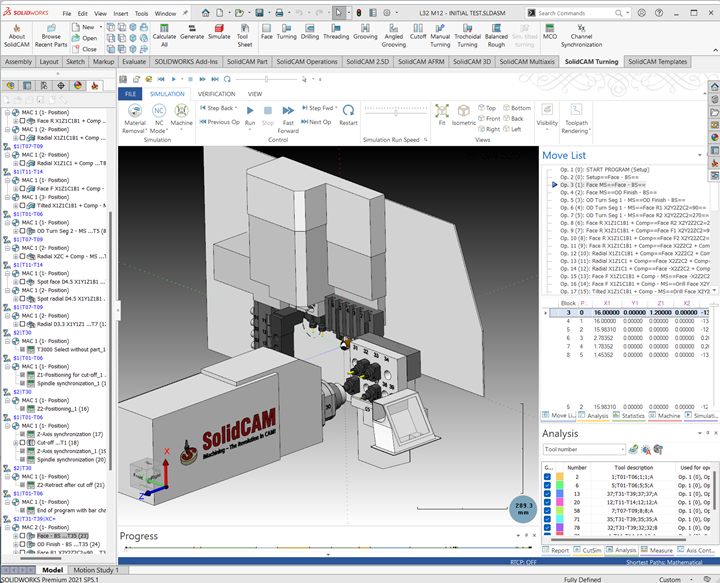

Channel synchronization helps to coordinate main spindle operations with subspindle operations to determine the most efficient machining process. This allows for crash detection and detection of interference issues within a Swiss multi axis. Screen shot provided by Shamrock Precision.

Synchronicity

The G and M codes for Swiss-type machining operations can look foreign to CNC programmers experienced with other machine types. This is a particular danger when it comes to programming the machine’s main spindle and subspindle to make coordinated machining passes. In SolidCAM, channel one may represent the main spindle and channel two the subspindle, and channel synchronization functions allow Holeman to coordinate these channels and avoid a potential collision.

This ability allows the user to program a part from start to finish on one channel, then test that code against another channel’s program. Multi-axis lathes can include multiple turrets, and the ability to synchronize those channels and insert wait markers (instructions for a given channel to pause) is a big step toward automating the process. Watching a simulation run, you can see the starts and stops of each spindle line up with the wait markers in the G code. Holeman says that watching simulations side-by-side with the corresponding G code enabled him to learn the nuances of Swiss-type programming relatively quickly — especially when he was able to see how the wait markers lined up with the actions of each spindle and turret.

The software also provides a time study that allows Holeman to see how the changes he makes to any channel’s operations affect overall machining time. “I can see how much time I’m saving by using the subspindle while the main spindle is operating,” he says. “I can save the program as a template, try it again, then choose the template that's the fastest and run it and post it.”

During a simulation run, the wait pauses for each channel are synchronized with the G code output. Viewing simulations side-by-side with the G code files allows new users to more quickly adapt to Swiss-type programming. Screen shot provided by SolidCAM.

This same feature can also detect potential clashes or collisions. When one channel is not capable of performing a specific motion while another channel is moving, the software will not allow the user to post out the code or run a simulation until the machine is back to a movable state. Early on, Holeman says, this was an aspect of the software that allowed him to avoid scenarios that could put that machine in danger. “If you have 10 operations in your subspindle, you can move them into the section of code where you think you want them and [SolidCAM] will show you interferences,” he says. “It will put a red line across the section and show you, nope, you can’t do that.”

On Pace

By the time I visited Shamrock Precision earlier this year, the Swiss department was fully operational. The company has been diversifying its customer base, taking on aerospace and defense projects and investing in five-axis with the purchase of a Makino a500z HMC. But in the Swiss department, more than a dozen Swiss-type lathes, including two Citizen L32s, eight A20s, and two Tsugami B0206s, are running non-stop across two shifts, on pace to produce tens of thousands of shear screws and other parts per year.

Four years after introducing Swiss-type machines into its operations and just only year after fully adopting a new CAD/CAM system, Shamrock Precision has met an ambitious challenge set out in 2017 by owner Corbin Embrey.

That the lion’s share of this work was achieved in less than two years — during a global pandemic — is testament to Embrey’s vision as well as Rob Holeman and his team’s dedication to making this department successful. Holeman says that he has spent countless hours on the phone with SolidCAM application engineers like Eric Middleby, and Greg Payton, who each guided Holeman through the transition.

“I can call Eric and have him on the line like that,” Holeman says, snapping his fingers. Embrey and Holeman credit this — real, human-interfacing customer service — as perhaps the most important feature of the platform. “Greg spent a week at Shamrock writing custom posts for both the A20 and the A32, and he matched the code to the way that our operators are used to seeing it. It’s a game changer when you’re dealing with a company that’s dedicated to getting this to work.”

Related Content

Inside the Premium Machine Shop Making Fasteners

AMPG can’t help but take risks — its management doesn’t know how to run machines. But these risks have enabled it to become a runaway success in its market.

Read MoreQuick-Change Tool Heads Reduce Setup on Swiss-Type Turning Centers

This new quick-change tooling system enables shops to get more production from their Swiss turning centers through reduced tool setup time and matches the performance of a solid tool.

Read MoreThe Future of High Feed Milling in Modern Manufacturing

Achieve higher metal removal rates and enhanced predictability with ISCAR’s advanced high-feed milling tools — optimized for today’s competitive global market.

Read MoreCNC Machine Shop Honored for Automation, Machine Monitoring

From cobots to machine monitoring, this Top Shop honoree shows that machining technology is about more than the machine tool.

Read MoreRead Next

When Handing Down the Family Machine Shop is as Complex as a Swiss-Turned Part

The transition into Swiss-type machining at Deking Screw Products required more than just a shift in production operations. It required a new mindset and a new way of running the family-owned business. Hardest of all, it required that one generation let go, and allow a new one to step in.

Read MoreShop's Success Turns on Swiss-type Technology

During the past few decades, the Swiss-type lathe has evolved from a niche product to a go-to platform for done-in-one production of small precision parts. This shop has evolved right along with it.

Read MoreRegistration Now Open for the Precision Machining Technology Show (PMTS) 2025

The precision machining industry’s premier event returns to Cleveland, OH, April 1-3.

Read More