-

SPONSORED

-

-

-

-

-

MMS Blog

CYCLO COOL 900 Series

(Sponsored Content) MAG’s CYCLO COOL 900 cutting fluid series has a unique formula that performs well within the aerospace industry in replacing typical soluble oils and semi-synthetics. These fluids provide huge cost savings in reducing non-scheduled cleanings, fluid maintenance and usage of MWF additives. Customers are also able to recycle these fluids without excessive amount of maintenance, equipment and additives.

Read MoreMind The Mechanicals Before Upgrading Your CNC

Don’t plan a control retrofit project too narrowly. Proper mechanical alignment is a key part of a comprehensive approach to upgrading a machine’s CNC.

Read MoreGoing Lean Has Positive Benefits For Metal Finishing

The rationale behind lean manufacturing applies very directly to metal coating and finishing processes. The cost savings are often greater than one might expect.

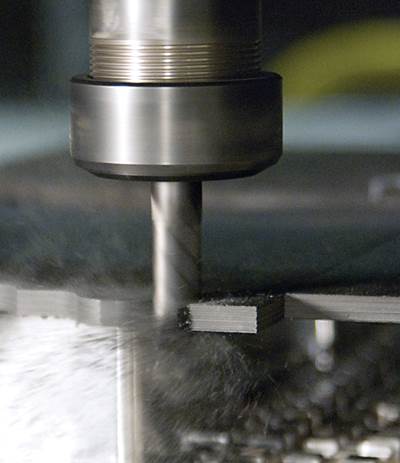

Read MoreCutters Compress To Effectively Machine Composites

The combined up-cut and down-cut spiral flutes on these cutters compress layered composites to prevent delamination during machining.

Read MoreApplying Minimum-Quantity Lubrication: 3 Articles and a Video

These three articles and a video explain why shops should consider minimum quantity lubrication.

Read MoreMachine Tool Specification Information Made Available To MMS Online Visitors

A powerful new capability will allow MMS Online visitors to compare machine tools by brand and capability to speed and simplify the search for the right machine.

Read MoreHow Stylus Choice Affects CMM Accuracy

Measurement uncertainty and inconsistency can result when an improper CMM stylus is chosen. A metrology products manufacturer details four aspects of stylus choice that can impact overall CMM accuracy.

Read MoreDiagnostic Software Stimulates Accurate, Timely Decisions

This component-based troubleshooting and diagnostic system is said to consolidate large amounts of manufacturing information in a format that enables technicians to quickly find exactly what they need.

Read MoreAluminum Molds In Three Weeks Or Less

While aluminum molds are commonly used to create prototypes or to serve as stopgap bridge tooling, they are starting to receive greater attention for production work. This shop’s approach to creating aluminum molds in one day to three weeks is the same for each of these situations.

WatchCYCLO COOL Cutting Fluids

(Sponsored Content) CYCLO COOL cutting fluids consist of a large range of premium metalworking fluids designed for the various dynamic metal manufacturing industries. More specifically, general job shop manufacturing facilities are extremely impressed with the ‘work horse’ nature of CYCLO COOL 1800 and CYCLO COOL 2000.

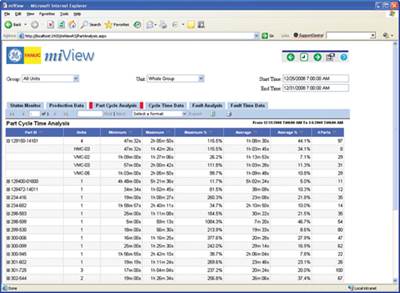

Read MoreAutomating Machine Monitoring And Data Collection

This automated machine data collection software automatically collects a wealth of information specific to machining processes and presents it in an intuitive format so users can quickly analyze the data and implement changes.

Read MoreCYCLO CUT HSK63A End Mills

(Sponsored Content) CYCLO CUT cutting tools offer integral shank HSK63A end mills for use in high speed machining of large aluminum structural components. Integral design allows indexable cutting while running at high RPM’s, and much higher cutting capabilities. Cutters are available up to 2.00” in diameter with reaches of 2.00” to 4.00”.

Read More