Machining Critical Crane Components

By investing in a new horizontal machining center with a two-axis head and a six-station pallet pool, this crane OEM is making critical components for telescopic booms in one setup and running lights-out.

Share

When a manufacturer of heavy-duty cranes used in construction decided to upgrade from the stand-alone, dual-pallet horizontal boring mill it was using to machine components for booms, it had very specific goals in mind. It wanted to reduce setups, increase machine uptime using automation and introduce lights-out manufacturing into its operation—something it had never before attempted. By collaborating with the local representative of a machine tool builder based in Germany, it achieved all this and more, including adding new part numbers to the 150-plus it already had planned to run across the machine.

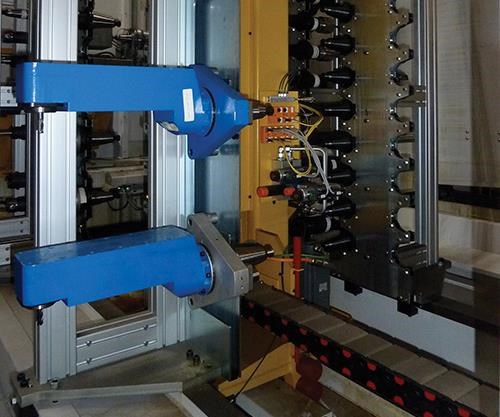

The system this crane OEM purchased, based on a horizontal machine platform, combined a variety of technologies to achieve these objectives. These include a two-axis head that can approach parts mounted on as many as five faces of a tombstone from vertical, horizontal and angular positions in one setup; a six-station pallet pool that enables employees to load new workpieces on multiple tombstones while the machine is cutting other parts; and a dedicated high-pressure coolant delivery and chilling system that enables it to maximize the benefits of new modular tooling that the company discovered. It also afforded the company the opportunity to sell its older machine, freeing up valuable floor space to potentially bring some outsourced fabrication work back in house.

Production Boom Times

Link-Belt Construction Equipment Co. employs some 700 workers at its 500,000-square-foot facility in Lexington, Kentucky. It manufactures components in seven categories of mobile cranes with an assortment of models within each. The division targeted for improvement machines critical components for five of its equipment categories, including the head at the very tip of the boom structure and the rear subweldments, or “subs,” at the other end, which bear a substantial portion of the weight of the boom and its load.

According to Tim Conway, production specialist at Link-Belt, although the horizontal boring mill it had long used to machine these parts was still operational, it was extremely slow, and its maintenance issues were escalating. Plus, its throughput was limited by its dual-pallet design. The machine sat idle as the employees unloaded single completed parts from the angle plate and then loaded four new workpieces on it, workpieces that required two setups and two separate part programs each.

Research led the company to machine tool manufacturer Burkhard+Weber (BW) LLC, which is part of Brazil’s Indústrias Romi S.A. and has a U.S. office in Erlanger, Kentucky, just south of Cincinnati, Ohio, and fewer than 100 miles from Lexington. Theodor Sprenger, BW territory manager, visited Link-Belt to learn about the company and its production needs. The questions for which he sought answers included whether the machine was producing a single part or a family of parts (family), the size and dimensions of the parts (rectangular, and generally no bigger than 2 feet wide by 5 feet high), the volume of output (high), and the materials being machined (steel).

After months of discussions, quotes on different machines and configurations, and a visit by Link-Belt personnel to see BW’s manufacturing facility in Germany, the company decided on a BW MCX 1200 HVP machine with a two-axis head and six-station pallet pool. Link-Belt leverages a variety of this system’s features to its advantage, including:

Two-axis head. The “HVP” in the machine model’s name refers to “horizontal, vertical and positioning.” The ability to approach workpieces from a variety of angular positions enables the company to machine multiple sides of parts fixtured to tombstones to complete parts in one setup. In some cases, the shop is able to fixture five workpieces on a single tombstone, one on each of the four vertical tombstone faces and one on the top horizontal face. While the fixturing was designed by Link-Belt and subcontracted to an outside specialist, it machined its own tombstones and has a total of nine: six small tombstones measuring 32 inches square by 58 inches tall, and three larger versions that are 40 inches square by 64.75 inches tall.

Mr. Conway says the working volume inside the machine is approximately 95 inches in diameter and 72 inches above the table, allowing for machining of the full range of components required for the boom. Its spindle delivers 55 hp and duty-rated torque of 900 foot-pounds.

For programming of the machine, production engineering manager Gary Gapp says the company has found the Siemens NX PLM software BW suggested to be helpful, especially because the software’s machine simulation function is capable of identifying potential interferences between the machine spindle, toolholder or cutter and the workpiece or fixturing elements. Link-Belt uses simulation on the first part of a new job to make sure there will be no breakdowns. This enables it to start production more quickly than before and with a higher degree of confidence.

Faster cycle times. The MCX 1200 offers rapid traverse rates of approximately 65 m/min. with an acceleration rate of 5 m/sec2. This reduces overall cycle times by reducing the time required for non-cutting positional movements. In addition, the system includes a high-capacity tool-management system with toolchanger that holds a maximum of 190 tools smaller than 120 mm and 17 tools larger than 160 mm. It can be field extended for a maximum of 350 tools. One advantage of this tool-change system is that the company can load a variety of duplicate or “sister” tools that will automatically replace a broken cutting tool if the tool-setting and broken-detection probe detects breakage or excessive wear, which is especially helpful when conducting lights-out machining. Other benefits include the ability to reduce tooling inventory with standardized tools.

Also, because the machine’s head can be positioned at numerous angles, it is possible for it to use longer tools to reach areas that were hard to machine on the old mill. In fact, this spurred Link-Belt to research new technology in longer cutting tools and purchase from Sandvik Coromant’s EH modular tooling line an exchangeable-head system that includes solid carbide heads, indexable milling cutters, boring heads, integrated machine adapters and different shanks. It works particularly well with large machining centers such as the MCX, because it offers long reach while retaining rigidity to minimize chatter, as well as reliability and accuracy thanks to the accurate interface between tool heads and shanks.

The MCX also features a self-contained, 725-psi coolant system that filters, cools and recirculates the cutting fluid within the machine. Mr. Gapp says this is preferable to hooking into the company’s plant-wide coolant delivery system, because it ensures that the coolant is clean and particulates don’t foul the machine’s moving parts. It also chills the fluid, allowing high-speed tooling to be used at higher feed rates. As a result, setup and cycle times have also been decreased. Setting up and machining the boom head, for instance, required two hours on the old machine, but that combined time has been slashed to 40 minutes on the MCX. Chilled coolant also stabilizes the workpiece, and high-pressure delivery clears chips from the cut while an overhead drench cleans the part and keeps the chips within the enclosure rather than carrying them out of the machine when they are unloaded.

Unattended production. Link-Belt knew it would benefit from the MCX’s six-station pallet pool, because employees could be fixturing new workpieces on tombstones outside the machine while it was cutting. But the company also found a side benefit in that it could load the machine to run a third shift unattended, whereas its previous machine ran just two manned shifts.

Having a machine tool that is “self-aware,” as Mr. Conway describes it, automatically checking tools and replacing those that are worn or broken, for instance, is critical for safe, lights-out machining. On-machine probing of parts is part of this self-awareness, enabling the machine’s coordinate system to be automatically adjusted to match the actual position of fixtured parts. Additionally, setup times have been reduced from approximately two hours on the previous mill to less than 40 minutes on the MCX.

Although much has been figured out on the shop floor since the machine went live more than a year ago, assistance from the manufacturer has been required at times, like when a power outage caused the machine to shut down and the operators were unsure of the proper procedure for restarting it. Mr. Conway provided the BW technicians in Germany with a password to the machine, which, despite the time difference between the two countries, allowed them to work on it overnight. The next morning, the MCX was up and running again.

As the company has dialed in its production process with the machine, it has found itself in the position to add new part numbers. Another project that has sprung from the experience of learning about and adapting to the many capabilities this new technology delivers involves a collaboration between the company’s engineering and IT departments. This team is developing bar codes to be attached to each face on the tombstones that can be read by the machine tool so that it can automatically assign the proper machining program.

Plus, with plans to sell the boring mill, the company finds itself with possible options such as expanding its welding operations to bring work that is currently being outsourced back in house. Not that the company is hurting for space, but the area now taken up by the old machine is immediately adjacent to its existing welding department, so it is an ideal location for such an expansion.

Related Content

CNC Machine Shop Honored for Automation, Machine Monitoring

From cobots to machine monitoring, this Top Shop honoree shows that machining technology is about more than the machine tool.

Read MoreInside the Premium Machine Shop Making Fasteners

AMPG can’t help but take risks — its management doesn’t know how to run machines. But these risks have enabled it to become a runaway success in its market.

Read More3 Ways Artificial Intelligence Will Revolutionize Machine Shops

AI will become a tool to increase productivity in the same way that robotics has.

Read MoreCutting Part Programming Times Through AI

CAM Assist cuts repetition from part programming — early users say it cuts tribal knowledge and could be a useful tool for training new programmers.

Read MoreRead Next

5 Rules of Thumb for Buying CNC Machine Tools

Use these tips to carefully plan your machine tool purchases and to avoid regretting your decision later.

Read MoreBuilding Out a Foundation for Student Machinists

Autodesk and Haas have teamed up to produce an introductory course for students that covers the basics of CAD, CAM and CNC while providing them with a portfolio part.

Read MoreSetting Up the Building Blocks for a Digital Factory

Woodward Inc. spent over a year developing an API to connect machines to its digital factory. Caron Engineering’s MiConnect has cut most of this process while also granting the shop greater access to machine information.

Read More

.jpg;maxWidth=970;quality=90)